Gapless Beam Dropping Method and Its Adjustable Height-adjusting Device after the Bridge is Highly Raised

A height-adjusting device and large-height technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in ensuring synchronization and stability, occupying equipment usage costs, and long working hours, so as to ensure elevation installation Accuracy, time saving, and simple use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

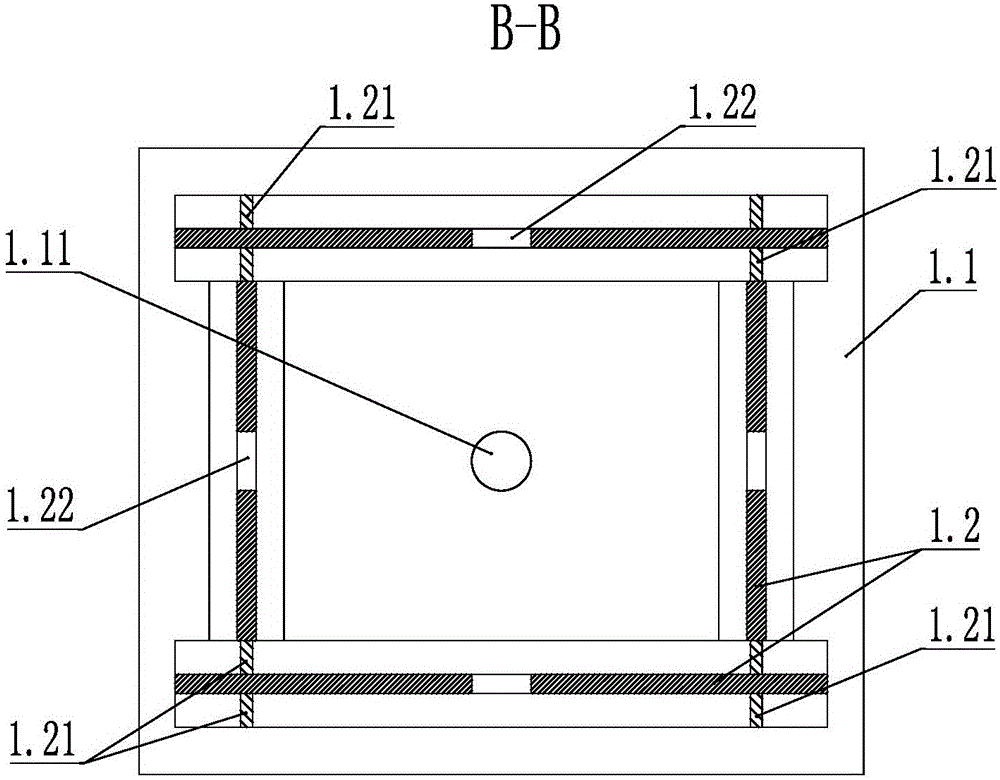

[0051] Such as image 3 As shown, the support platform 1 of the height-adjustable device includes a thick steel plate top plate 1.1 and a connecting beam 1.2; the top plate 1.1 is provided with a vent hole 1.11, and the vent hole 1.11 is located at the center of the top plate 1.1. Of course, it can also be combined with the actual situation. The exhaust holes 1.11 are arranged at other positions of the top plate, and a plurality of exhaust holes 1.11 can also be arranged on the top plate 1.1. In this way, when pouring the pouring layer, the air bubbles during pouring concrete can be removed as much as possible. The connecting beam 1.2 is a rectangular or square frame composed of vertically and horizontally cross-connected section steel, and the first stiffener 1.21 can be arranged at the connection, so that the connection is more reliable; the connecting beam 1.2 is provided with a grouting hole 1.22. This facilitates the entry of concrete as the pour progresses.

[0052] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com