Deviation-preventing and fast-drilling drilling assembly

A drilling tool assembly and deflection prevention technology, which is applied in directional drilling and other directions, can solve the problems of limited popularization and application, high cost, performance impact, etc., and achieve the effects of wide application range, stable performance and excellent deflection prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

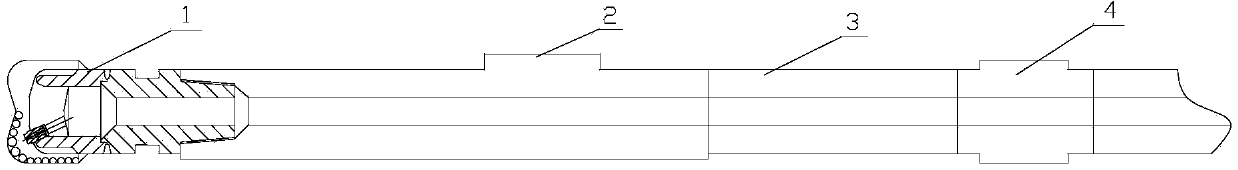

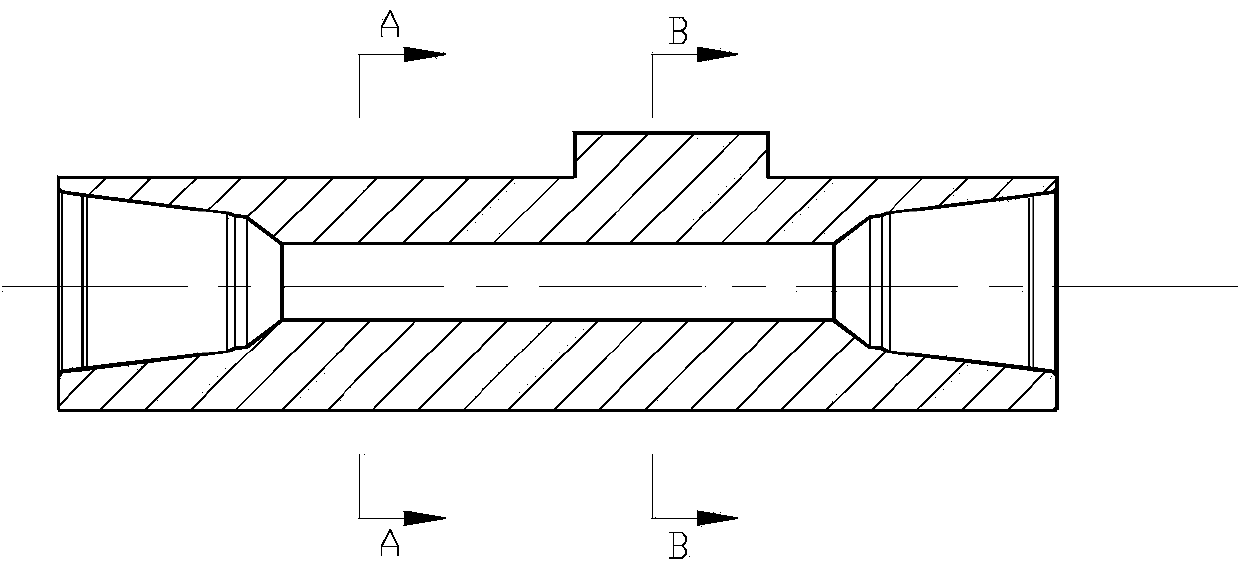

[0021] like figure 1 As shown, the anti-deviation fast drilling tool assembly includes: drill bit 1, eccentric deflection lever structure pup joint 2, drill collar 3, centralizer 4; drill bit 1, eccentric deflection lever structure pup joint 2, drill collar 3, centralizer 4 connected by threads in turn. When in use, the drill bit 4 is located at the bottom of the well and is used for rock-breaking drilling; the eccentrically deflected lever structure nipple 2, drill collar 3, and centralizer 4 are combined to form a combined structure for changing the force and cutting state of the drill bit, thereby changing Drilling trend; the centralizer 4 is connected to the drill tool assembly on its upper part.

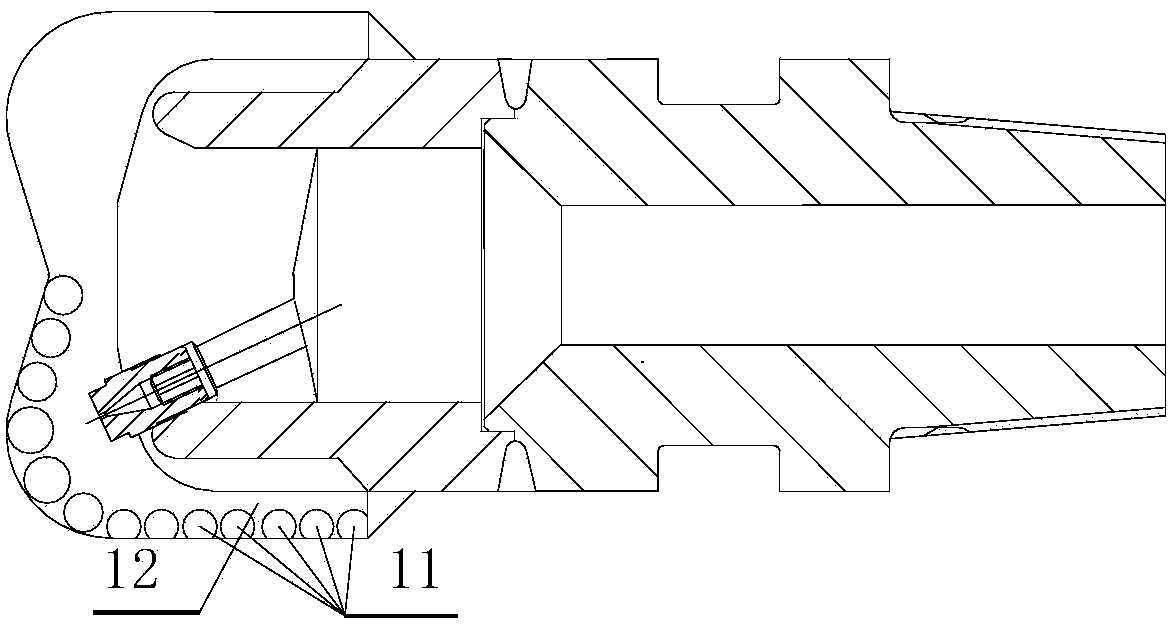

[0022] The drill bit 1 is evenly distributed with cutting teeth 11 on the diameter gauge part 12 of the drill bit blade, and the drill bit cutting teeth 11 are used to strengthen the lateral cutting ability of the drill bit 1 . When the drill bit is subjected to the same magni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com