Coal mine fully-mechanized excavation face short-distance comprehensive dedusting method

A working face, short-distance technology, applied in the fields of dust prevention, mining equipment, earth-moving drilling, etc., can solve the problems of mine safety production threats, harsh working environment of employees, affecting employees' physical and mental health, etc., to ensure safe production and occupational safety. Effects on health, inhibition of backward escape, risk reduction and incidence of pneumoconiosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

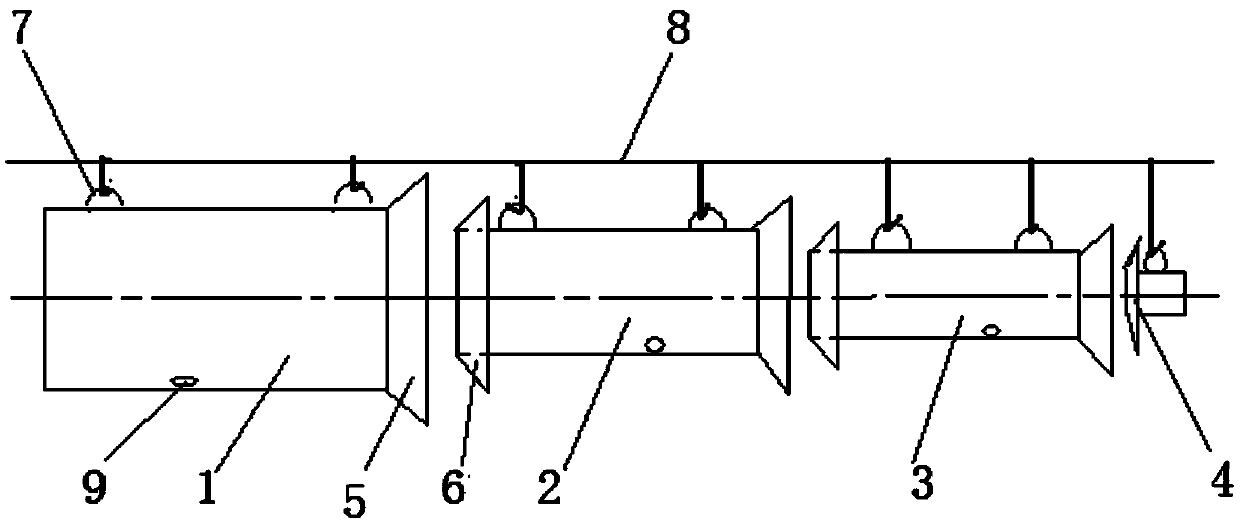

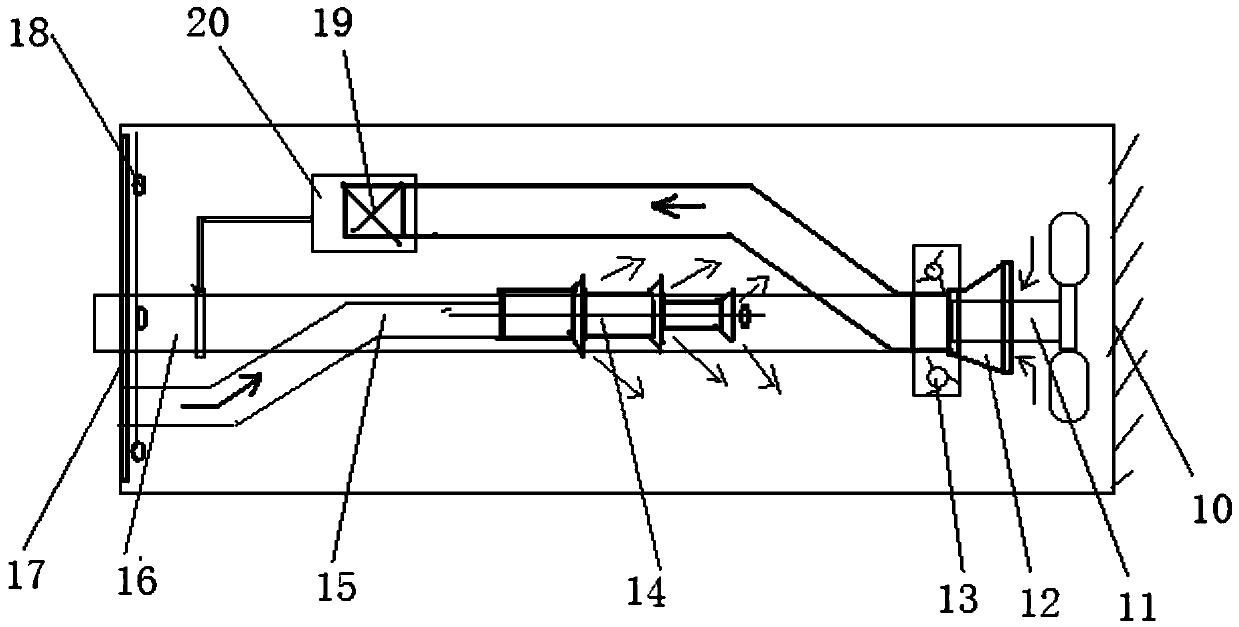

[0019] like figure 2 The short-distance comprehensive dust removal method for the fully mechanized excavation face of the coal mine shown, the steps are as follows:

[0020] Step 1, arrange the upper wet-type vibrating wire dedusting fan 19 within 20 meters from the fully mechanized excavation working face. The tail 16 of the second conveyor belt moves together along the belt-mounted track; the wet vibrating wire dust removal fan 19 is linked with the fully mechanized excavator 11; the air volume of the wet vibrating wire dust removal fan 19 is required to be greater than 200m 3 / min, the air suction port 12 of the wet-type vibrating wire dust removal fan 19 is designed as a bell mouth type air suction port, and the air suction port 12 is arranged between the cutting part of the comprehensive excavator and the loading machine 13 of the fully mechanized excavator, and is not far from the working surface. Greater than 3 meters, the wet vibrating wire dust removal fan 19 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com