Ignition method for boiler by utilizing methyl alcohol

A technology of boiler ignition and methanol, which is applied in the field of boilers, can solve the problems of thermal power generation fuel restrictions, etc., and achieve the effect of reducing oil consumption, reducing investment and operating costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

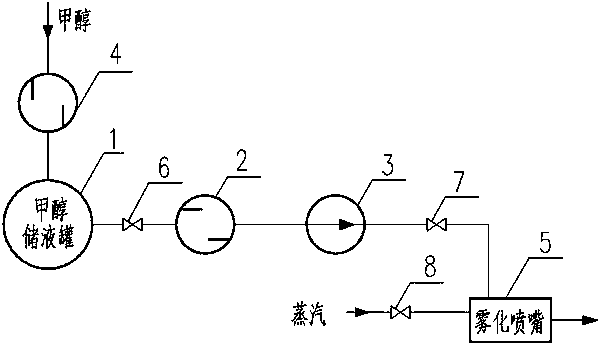

[0016] refer to figure 1 , the invention provides a kind of method utilizing methanol to ignite a boiler, specifically comprising the following steps:

[0017] Step A: Methanol is stored in the methanol liquid storage tank 1 after being filtered through the methanol coarse filter 4;

[0018] Step B: use the methanol pump 3 to inject the methanol in the methanol liquid storage tank 1 into the methanol fine filter 2 to filter, and inject it into the atomizing nozzle 5;

[0019] Step C: send the steam from the boiler into the atomizing nozzle 5, mix with the methanol in the atomizing nozzle 5 and make the methanol heat up and atomize;

[0020] Step D: Mix the atomized and heated methanol and air into the boiler and ignite it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com