Heat exchange plate structure in brazed plate heat exchanger

A technology of heat exchange plates and heat exchangers, which is applied in the field of machinery, can solve the problems of consuming large amounts of copper raw materials, and achieve the effects of saving copper materials, improving welding efficiency, and ensuring welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

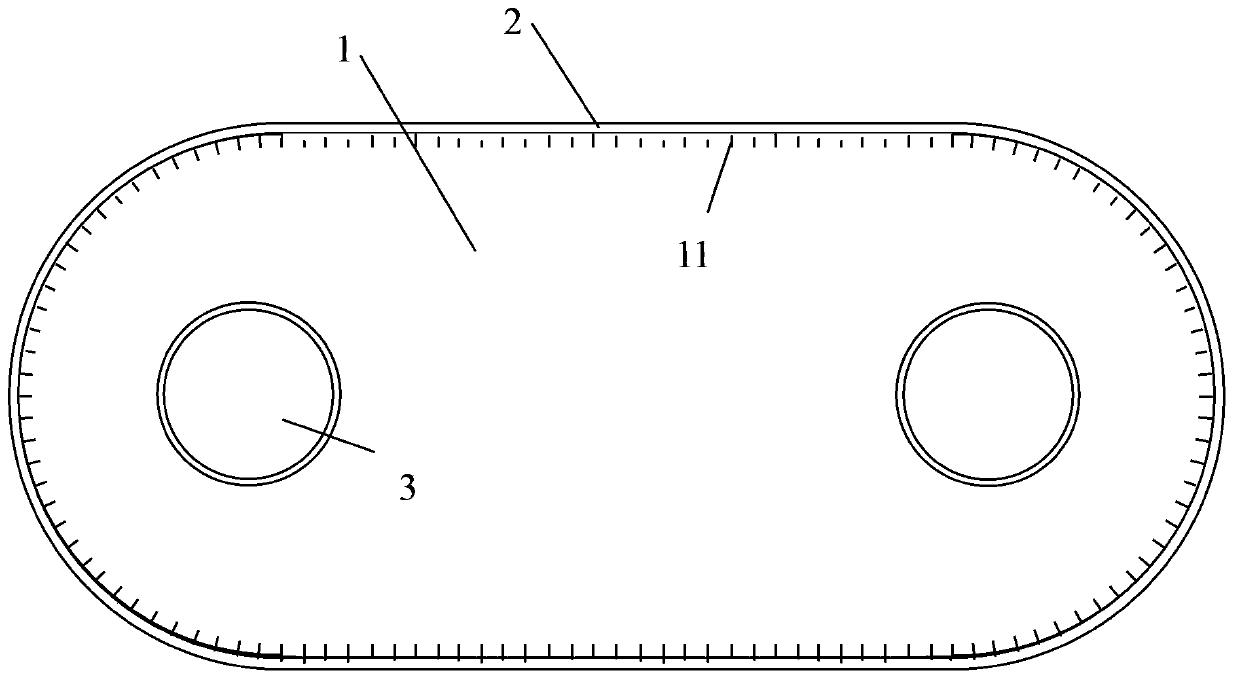

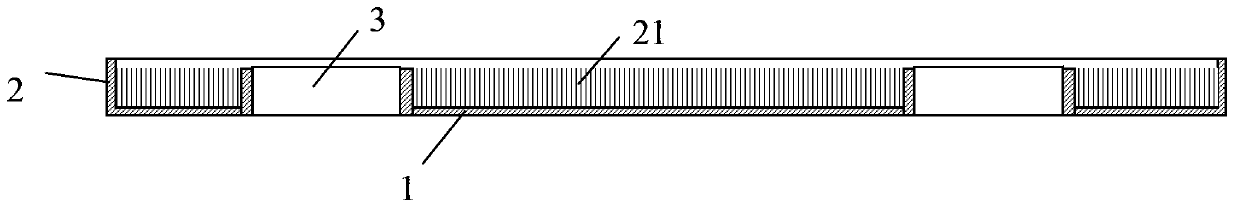

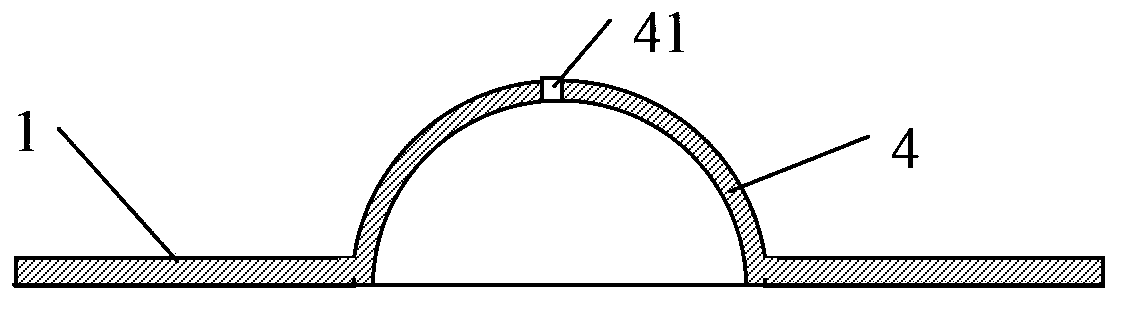

[0019] Such as figure 1 and figure 2 As shown, the heat exchange plate structure in the brazed plate heat exchanger of the present invention is composed of a metal sheet 1, and the periphery of the metal sheet 1 is provided with a flange 2 on the upper side, wherein the upper surface of the metal sheet 1 A plurality of bottom surface shallow grooves 11 are equidistantly distributed along the periphery of the side surface, and a plurality of sidewall shallow grooves 21 are equidistantly distributed along the periphery of the metal sheet 1 on the inner surface of the flange 2, any one There is a distance between the upper end of the side wall shallow groove 21 and the upper edge line of the flange 2 .

[0020] Further, the inner surface of the flange 2 is perpendicular to the upper surface of the metal sheet 1, the number of shallow grooves 21 on the side wall is equal to the number of shallow grooves 11 on the bottom surface, and any one shallow groove 21 on the side wall and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com