Load measuring device and measuring method thereof

A technology of load measurement and load, which is applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of bulky, expensive, and limited range of load measuring devices, and achieve the effects of practicability, low cost, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

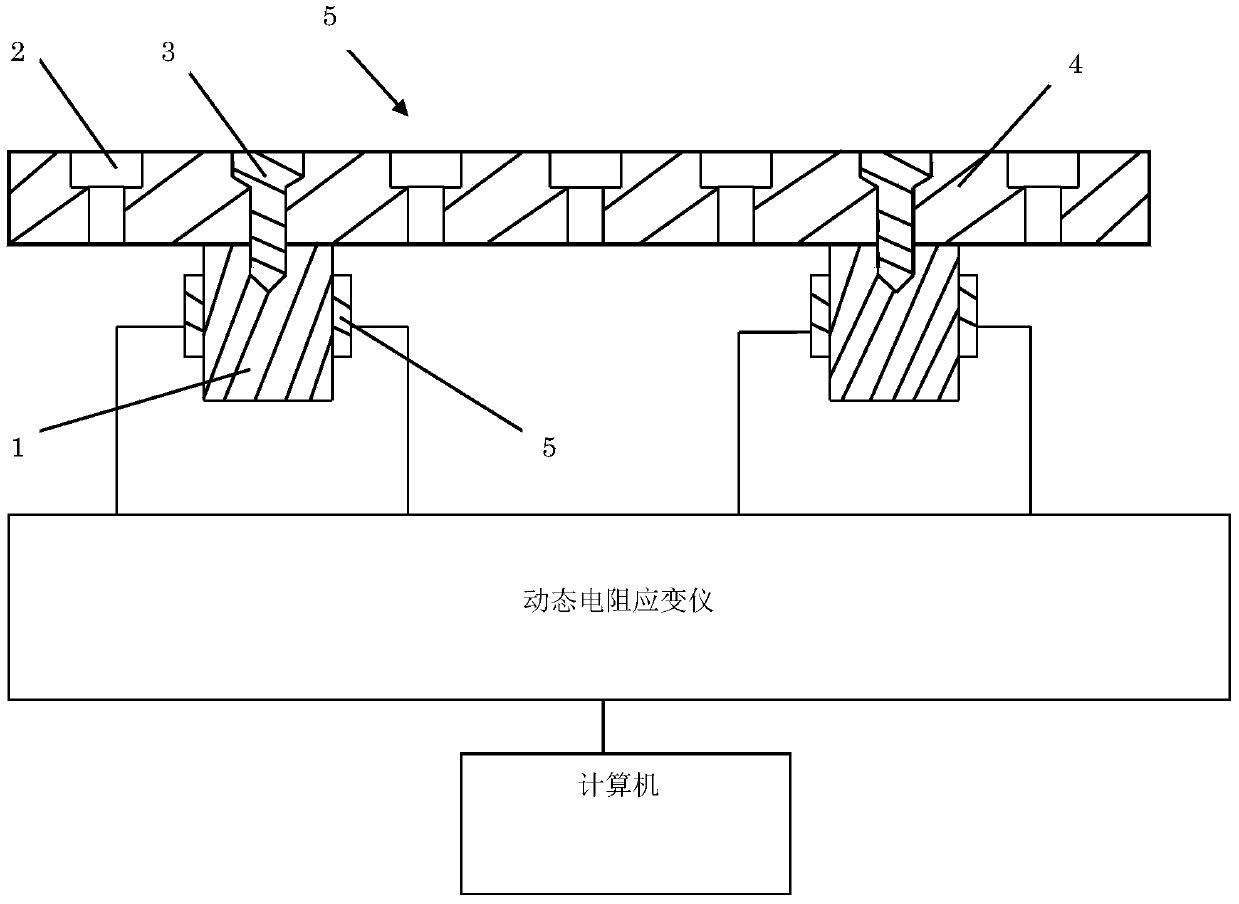

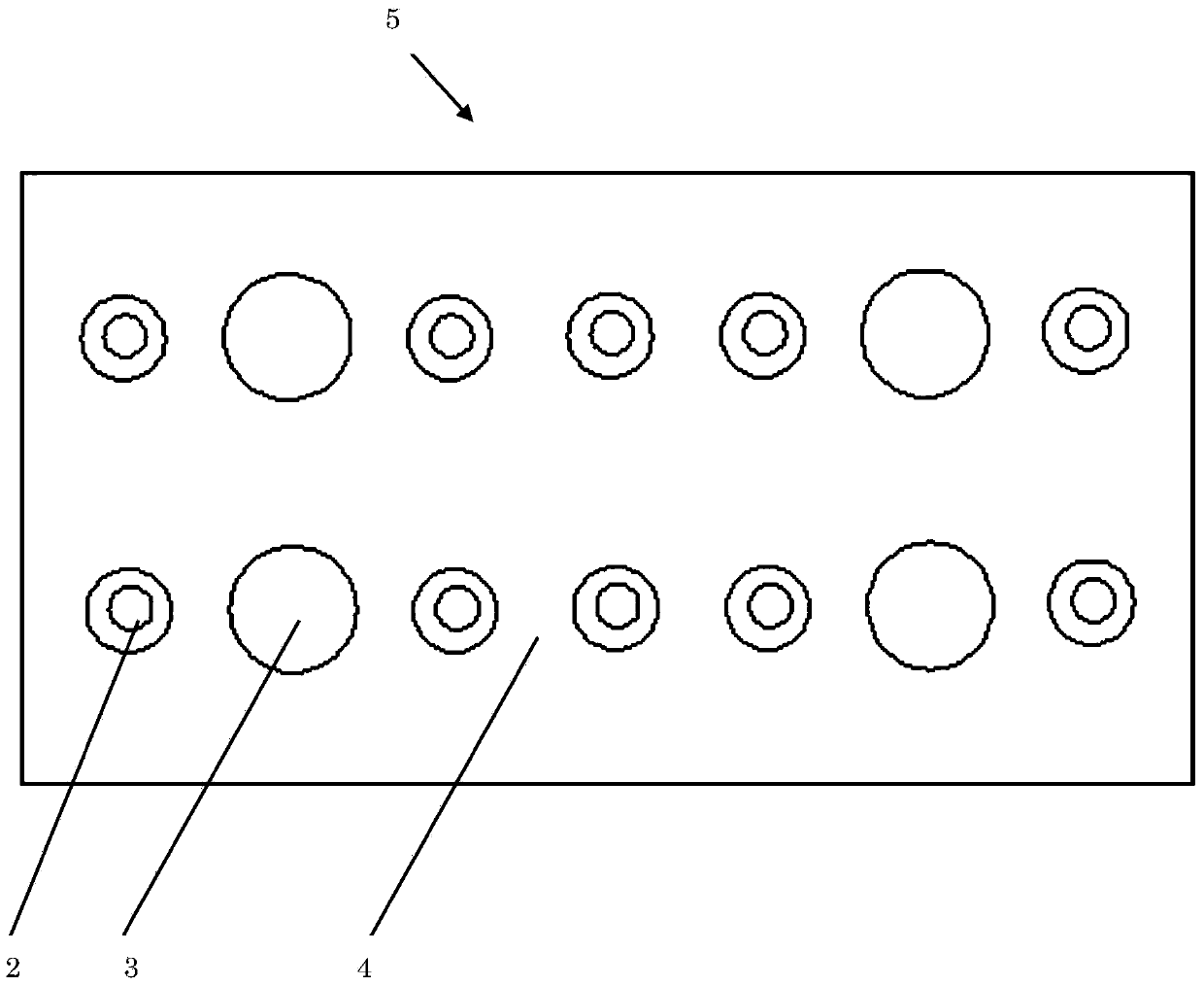

[0042] figure 1 is a schematic diagram of the cross-sectional structure of the load measuring device of the present invention in an embodiment.

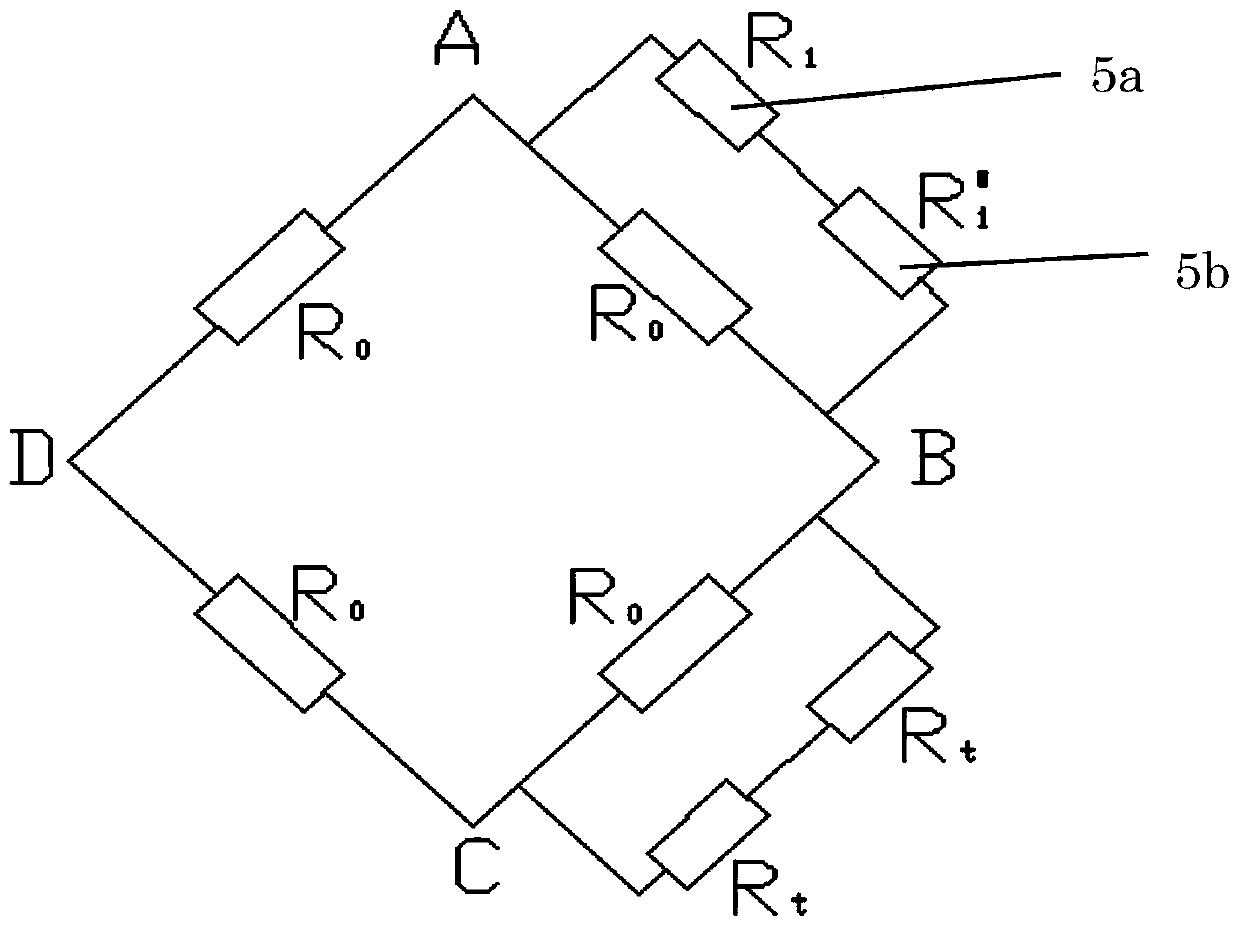

[0043] Such as figure 1 As shown, the supporting part of the load measuring device 5 includes a bearing plate 4 and four bearing columns 1. The ratio of the height to the diameter of the bearing columns 1 is 1.5:1, and the material used is a metal material with good elasticity. The level of the whole device is such that each bearing column 1 is subjected to an equal load, wherein the symmetrical position on each bearing column 1 is polished and used to attach two series resistance strain gauges 5a and 5b, and one bearing column 1 The two resistance strain gauges 5a and 5b are connected to the dynamic resistance strain gauge of the measuring section. The dynamic resistance strain gauge is connected to the computer of the data processing department.

[0044] The bearing plate 4 is connected with the bearing columns 1 by screws 3. Si...

Embodiment 2

[0066] This embodiment provides a method for measuring load using the above-mentioned load measuring device, and the specific steps are as follows:

[0067] Step 1: First select the size of the load-bearing column so that the ratio of height h to diameter D is 1.5, measure the cross-sectional area of the load-bearing column to meet the requirements of GB / T7314-2005 metal material room temperature compression test method, and then load the column that meets the size requirements Grind the front and back symmetrical parts on the cylinder surface in the middle of the column, and paste the resistance strain gauge.

[0068] Step 2: Pre-compress the load-bearing columns with the strain gauges pasted on them within the elastic range with as large and the same preload as possible, and measure the elastic modulus E of all the load-bearing columns;

[0069] Step 3: Connect the bearing column with the bearing plate with screws, and at the same time connect the two resistance strain gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com