Electromagnetic ultrasonic probe with variable structure

An electromagnetic ultrasonic, variable technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. and other problems to achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

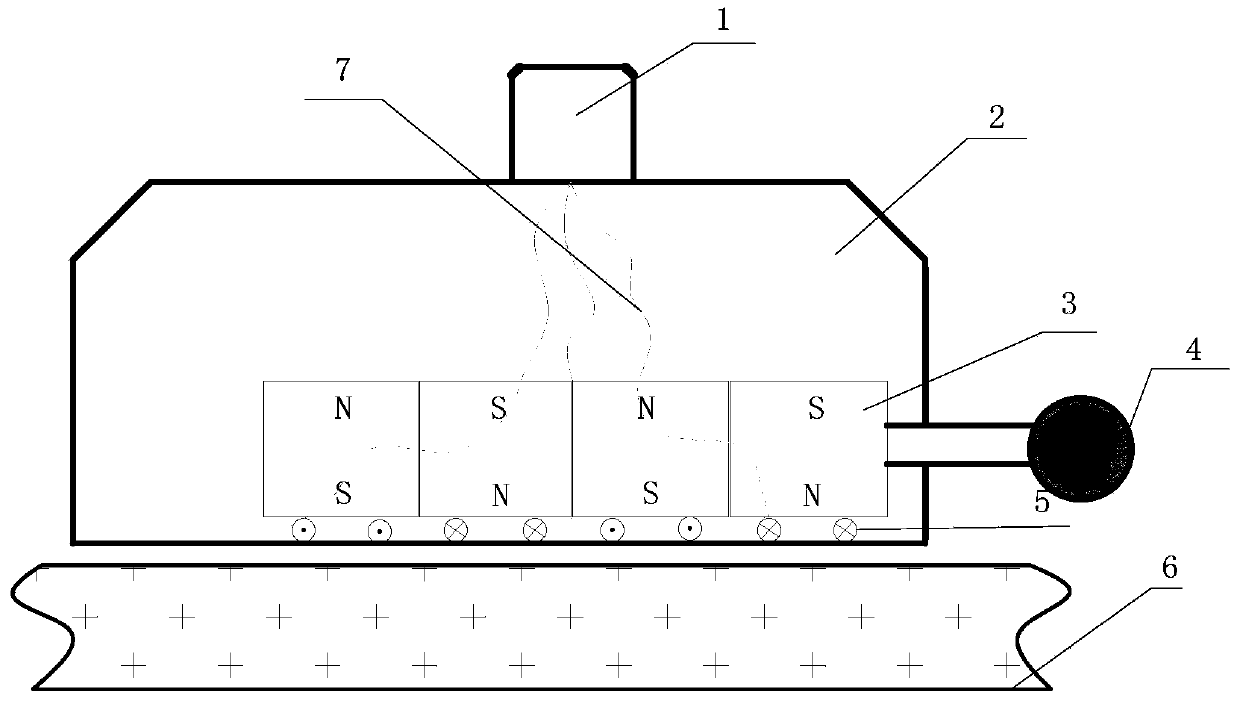

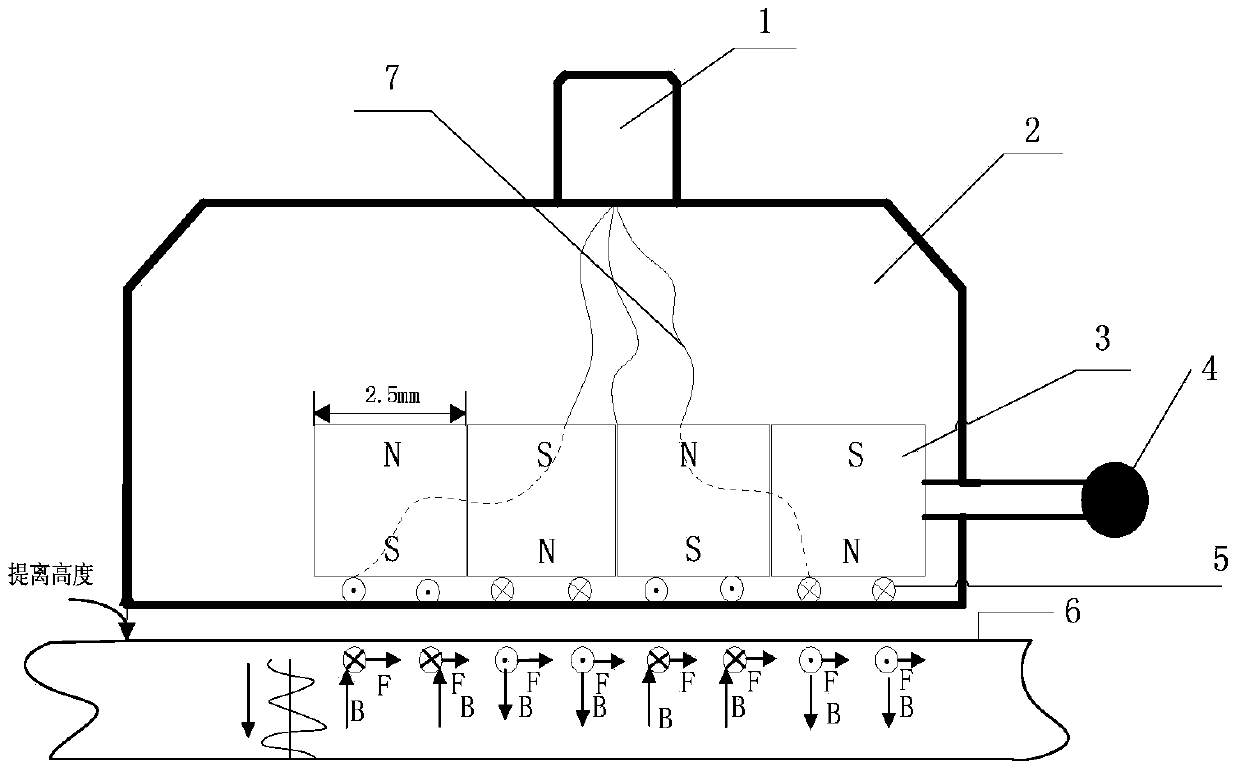

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. refer to figure 1 , the present invention provides an electromagnetic ultrasonic probe with a variable structure, including a probe interface 1 , an anti-interference shield 2 , a bias magnetic field 3 , a lever 4 , an EMAT coil 5 , and a connecting wire 7 . The bias magnetic field 3 is provided by a periodic magnet, and the periodic magnet is formed by splicing four equal and large square N42-type RuFeB.

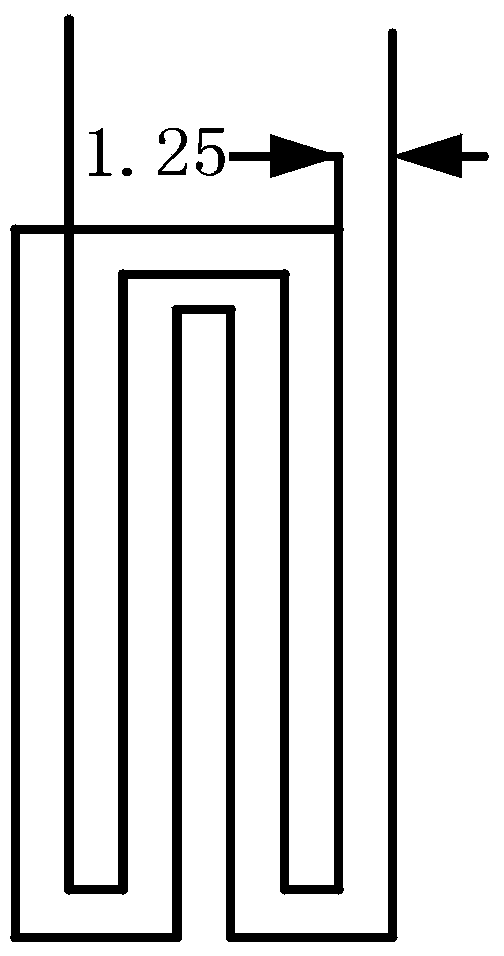

[0025] In this embodiment, the EMAT coil 5 is printed on a 0.5mm thick PCB, the line spacing S2=1.25mm, and the line width is 0.3mm. There are 2 wires under a single square N42 type RuFeB; the winding method is as follows figure 2 shown. The EMAT coil 5 is placed under the periodic magnet and placed in the anti-jamming shield 2 . The driving rod 4 is inserted into the sliding sleeve, and the sliding sleeve and the anti-interference shielding cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com