Optical proximity correction method for improving process window

A technology of optical proximity correction and process window, applied in the field of optical proximity correction, can solve the problem of not considering the size error of the mask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

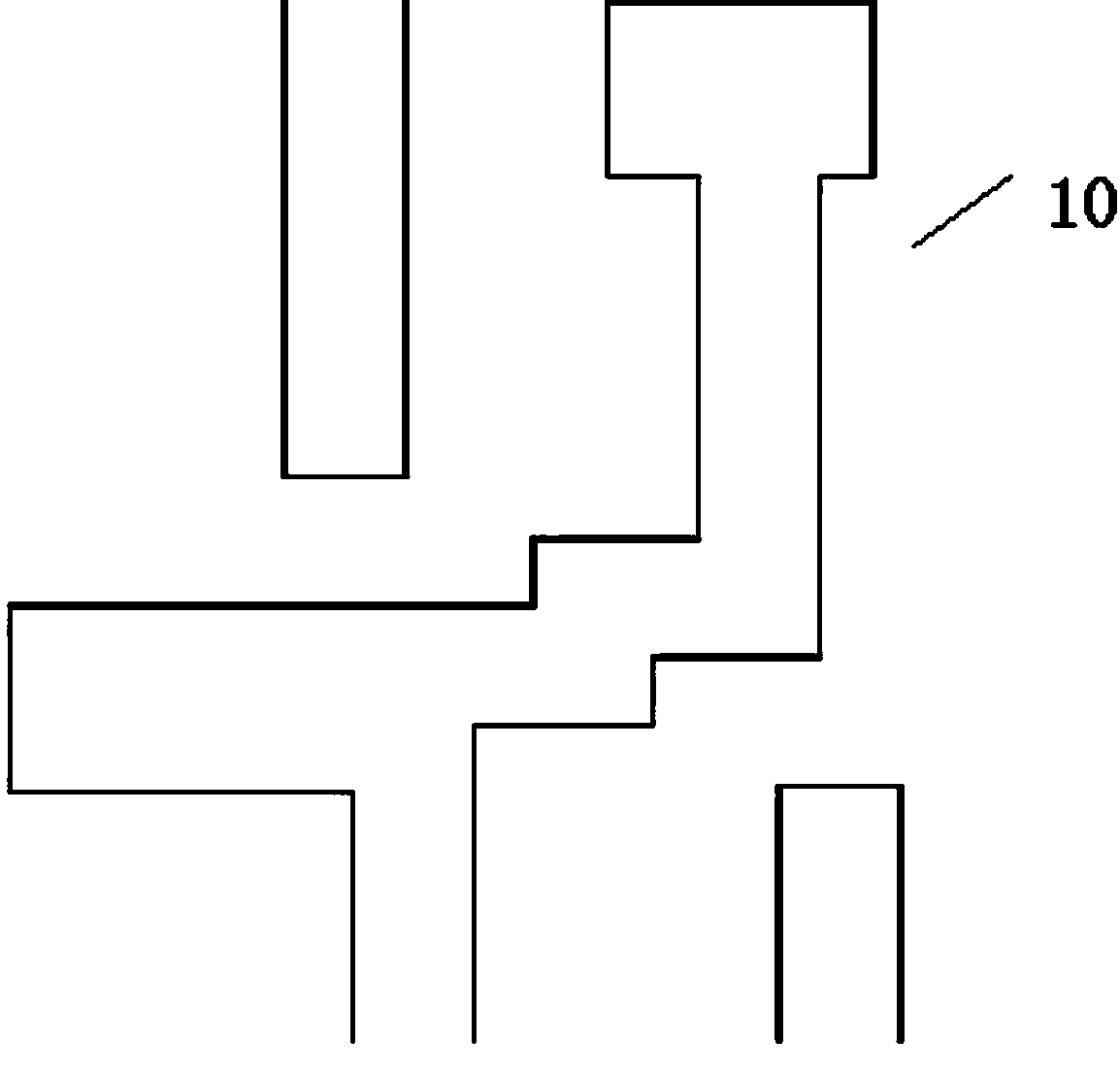

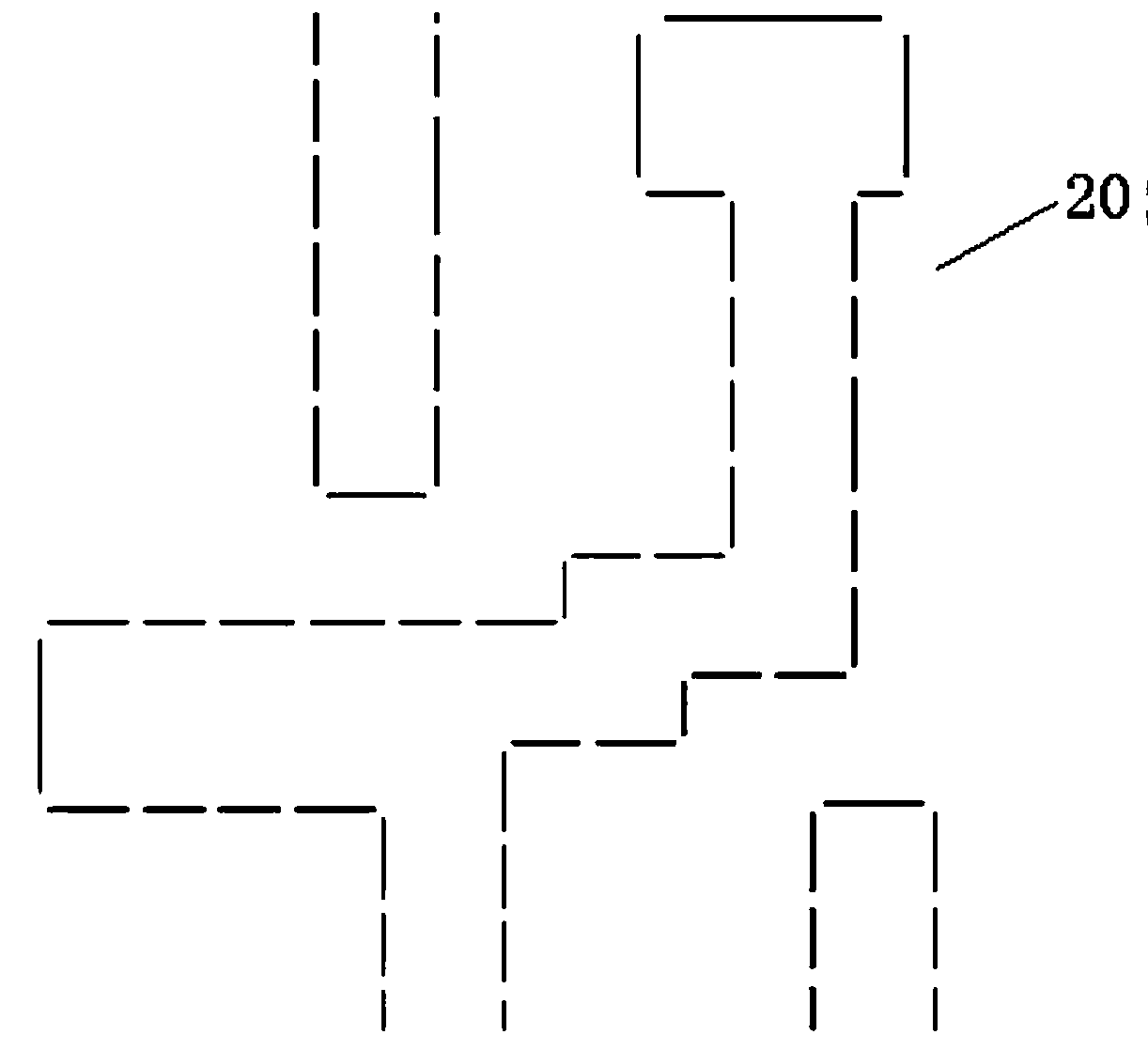

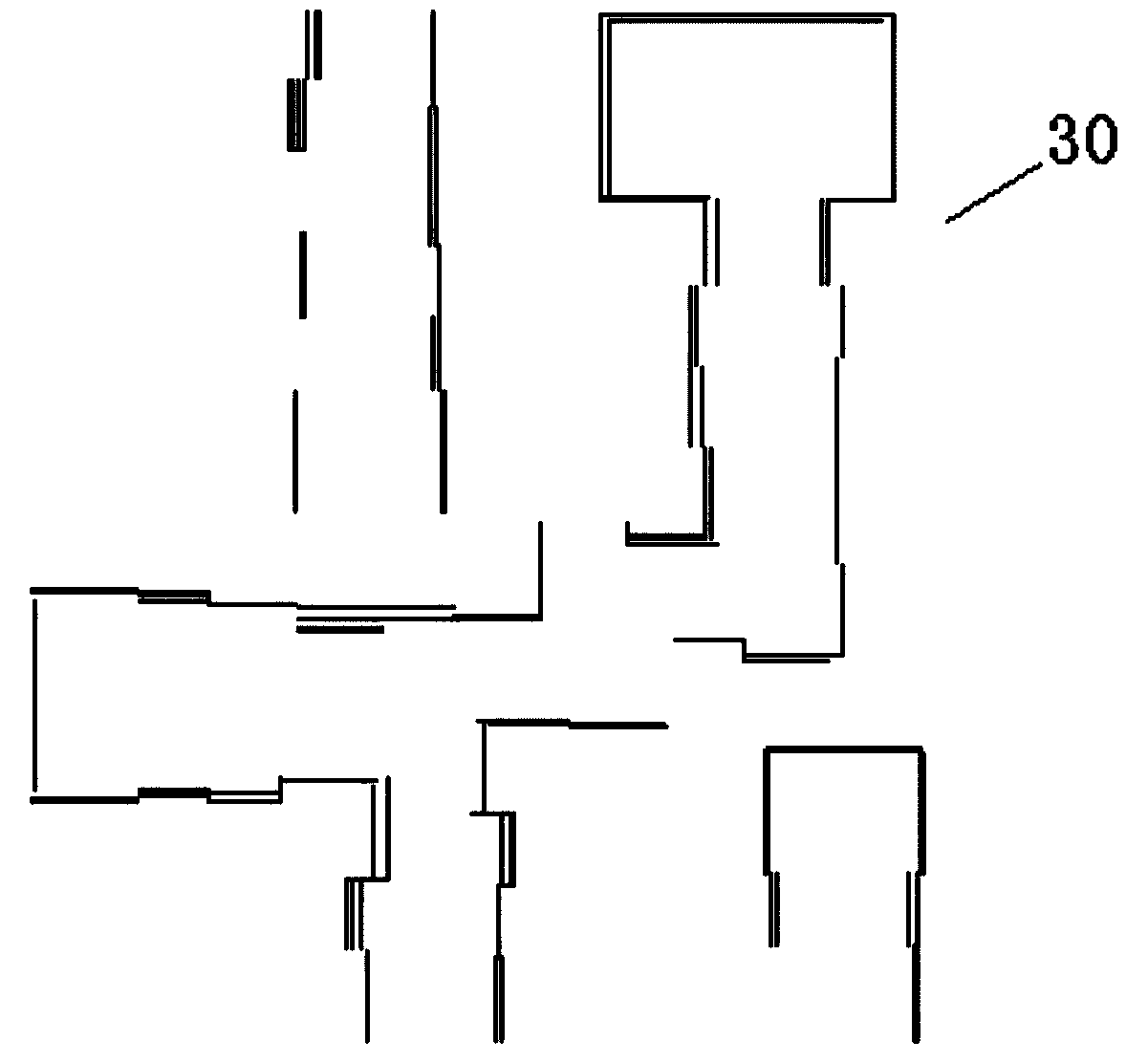

[0028] At present, the general model-based optical proximity correction OPC processing flow is as follows: firstly, the target graphics 10 (such as figure 1 ) for input, and then according to certain rules to cut the edge of the target graph into line segments, such as figure 2 As shown; the cut line segment 20 can be offset or corrected according to a certain calculation method, such as image 3 shown; before correction, the imaging result of the target figure is simulated 50 (such as Figure 5 ), correct according to the deviation (EPE) between the simulated contour and the target graphic, and then simulate again after correction and compare it with the target graphic. If several rounds are repeated, the final optical proximity correction O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com