Light-emitting diode and preparation method thereof

A technology of light-emitting diodes and light-emitting layers, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. It can solve problems such as device damage, reduce the risk of contact, reduce the annealing time, and reduce the degree of roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

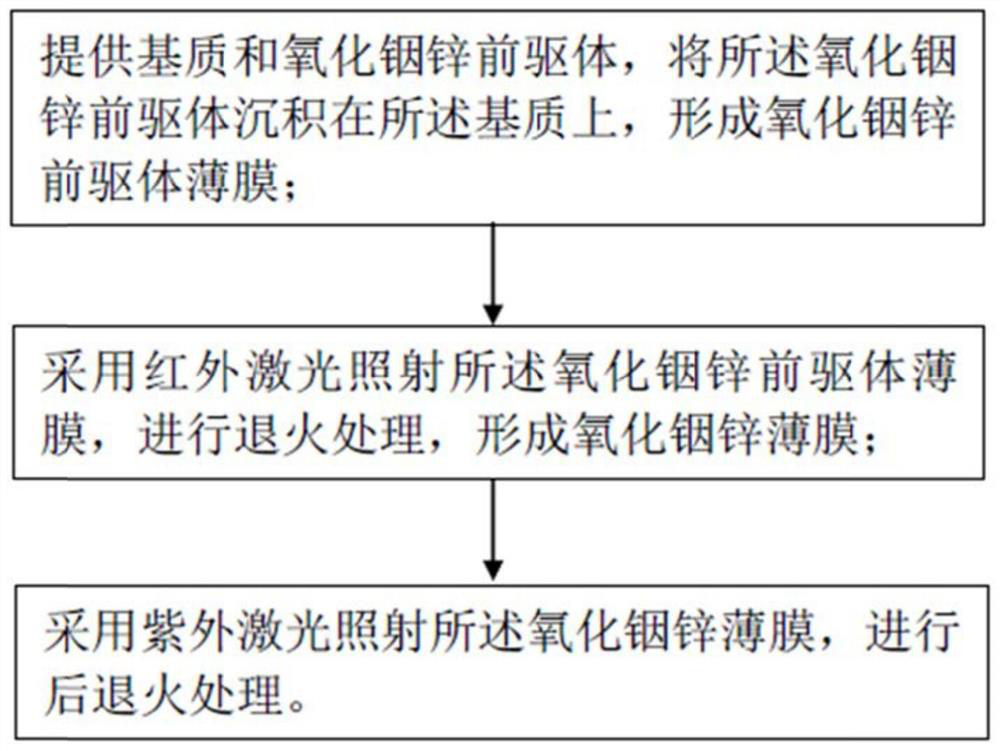

[0019] A kind of preparation method of light-emitting diode, such as figure 1 shown, including the following steps:

[0020] S01, providing a substrate and an indium zinc oxide precursor, depositing the indium zinc oxide precursor on the substrate to form an indium zinc oxide precursor film;

[0021] S02, irradiating the indium zinc oxide precursor thin film with an infrared laser, and performing annealing treatment to form an indium zinc oxide thin film;

[0022] S03, irradiating the indium zinc oxide thin film with an ultraviolet laser, and performing a post-annealing treatment.

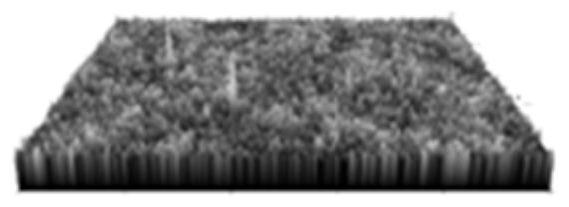

[0023] The preparation method of the light-emitting diode provided by the embodiment of the present invention, on the one hand, uses an infrared laser to irradiate the indium zinc oxide precursor film, so that the temperature of the material surface is instantly increased to generate a thermal effect, so as to form the indium zinc oxide film, thereby achieving the purpose of annealing, short-term ...

Embodiment approach

[0026] As an implementation manner, a light-emitting layer is formed on the substrate;

[0027] The step of depositing the indium zinc oxide precursor on the substrate includes: depositing the indium zinc oxide precursor on the light emitting layer.

[0028] An indium zinc oxide precursor is deposited on the light emitting layer, thereby forming an indium zinc oxide thin film on the light emitting layer. Since the embodiment of the present invention adopts the annealing method of infrared laser and ultraviolet laser successively, while greatly shortening the annealing time and improving the performance of the film layer, it also takes into account the possible impact of annealing on the light-emitting layer materials such as quantum dots, etc., from the overall The performance and lifetime of the device are improved.

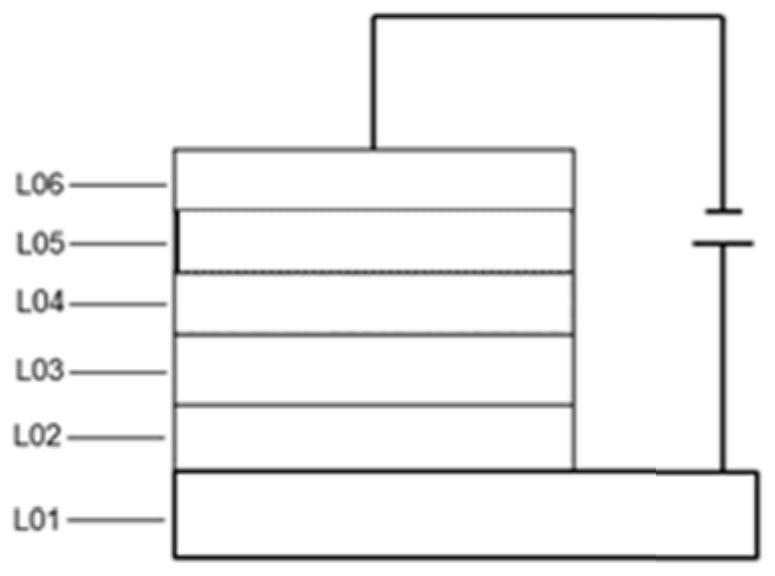

[0029] In some embodiments, the substrate includes: an anode, and the light-emitting layer is formed on the anode.

[0030] The material of the anode can refe...

Embodiment 1

[0062] In this embodiment, a light-emitting diode is prepared, which specifically includes the following steps:

[0063] 1. Preparation of IZO precursor solution

[0064] First put 0.1M of [In(NO 3 ) 3 ·xH 2 O] The powder is placed in a reagent bottle, and then 2.5ml of ethylene glycol methyl ether, 50ml of acetone, and 22.5ml of ammonia are added to the bottle. Then prepare another reagent bottle, add 0.1M [Zn(CH 3 COO) 2 2H 2 O] powder, 1.5 ml of ethylene glycol methyl ether and 30 ml of acetone. The two reagent bottles were placed in a magnetic stirrer, and stirred at a speed of 700 rpm for one hour in an environment of 60°C. The obtained two solutions were mixed at a ratio of one to one, and then fully stirred at a speed of 500 rpm for three hours in an environment of 27° C. to obtain an IZO precursor solution.

[0065] 2. Preparation of light-emitting diodes

[0066] (1) Spin-coat PEDOT:PSS on an ITO glass substrate at a speed of 5000 rpm for 30 seconds, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com