A kind of armored cable mechanical locking joint

An armored cable and mechanical lock technology, applied in the field of mechanical locking joints and armored cable mechanical locking joints, can solve the problems of uneven force, uneven arrangement of steel wires, extrusion and fracture of steel wires, and achieve uniform stress. Consistent, safe and reliable use, easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

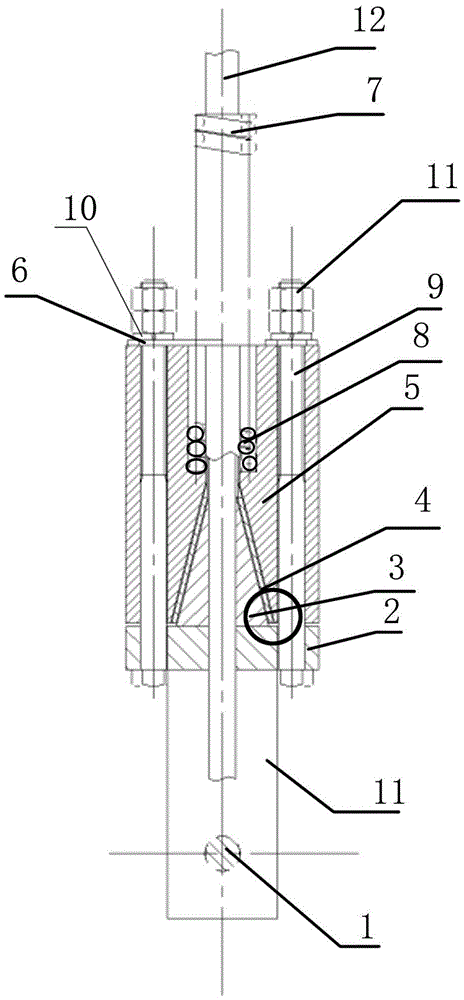

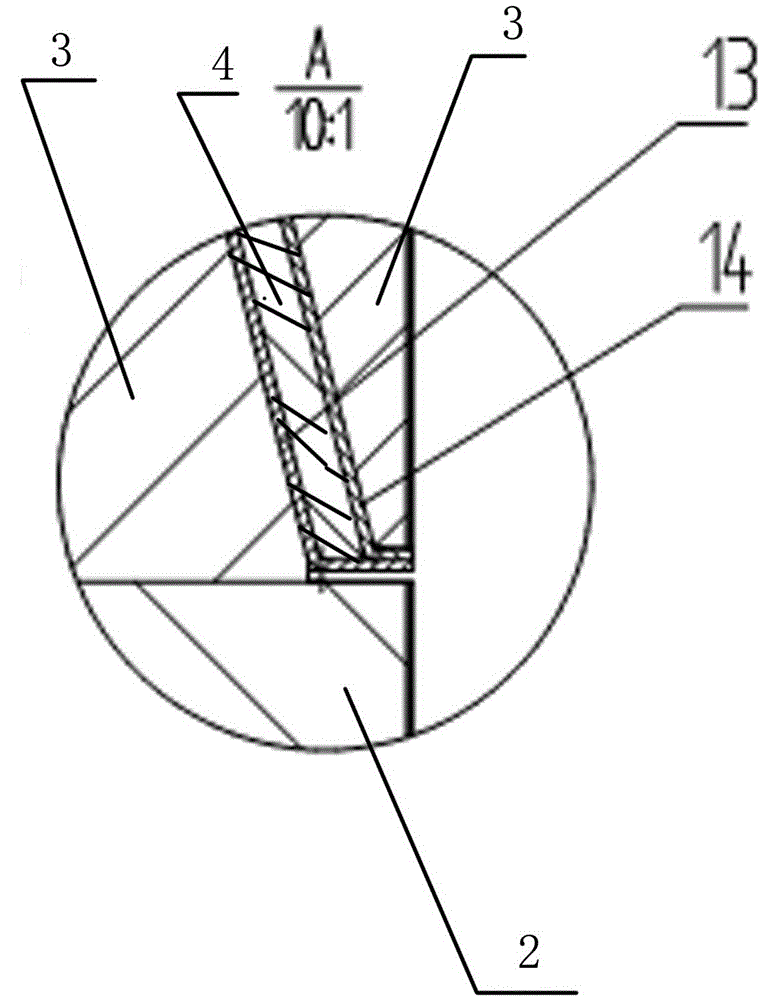

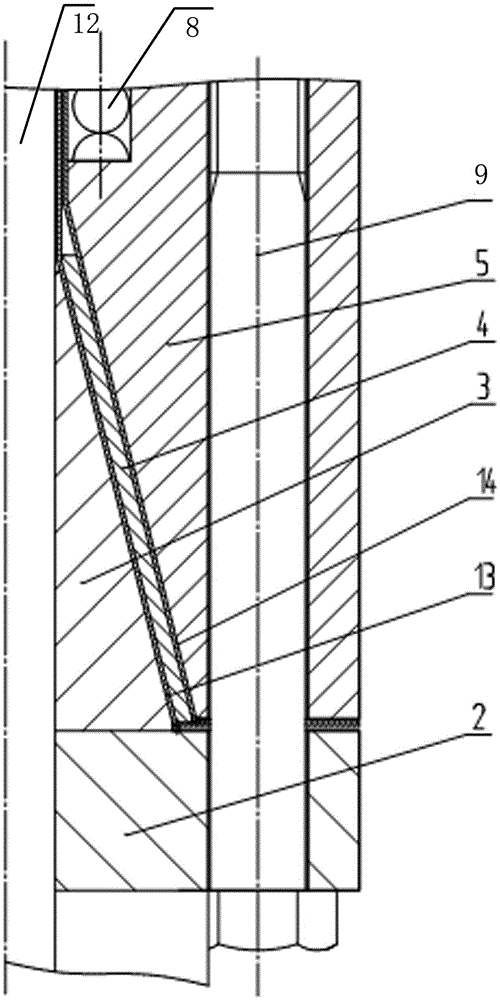

[0026] The armored cable mechanical locking joint of the present invention is mainly composed of a pin shaft, a U-shaped frame, an inner cone, an outer cone, a clamp body, a spring limit piece, a cable protection spring, a bolt, a flat washer, a spring washer, a compression nut, an armored It is composed of the cable and other components, the axis of the clamp body is drilled through the cable, and one end is a tapered hole; the outer steel wire of the armored cable of the mechanical locking joint is arranged between the clamp body and the outer cone, and the inner steel wire is arranged outside Between the cone and the inner cone; armored cable mechanical locking joints, the inner cone and the outer cone are designed with guide wire grooves evenly distributed along the edge.

[0027] Working principle: the outer steel wire 14 in the armored cable 12 of the mechanically locked joint is evenly arranged between the clamp body 5 and the outer cone 4, and the inner steel wire 13 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com