Structure increasing cast aluminum rotor iron core ventilation area

A technology of iron core ventilation and rotor iron core, which is applied in the shape/style/structure of the magnetic circuit, rotating parts of the magnetic circuit, etc., can solve the problems of poor heat dissipation effect, and improve the heat dissipation capacity, performance parameters and force performance index guarantee. , The effect of increasing the working air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

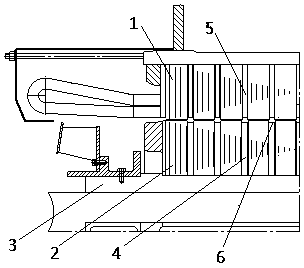

[0009] Such as figure 1 The shown structure for increasing the ventilation area of the cast aluminum rotor core includes a plurality of stator core segments 1 arranged at intervals and a plurality of rotor core segments 2 arranged at intervals, and the stator core segments 1 and rotor core segments 2 are arranged opposite to each other. The two ends of the rotor core section 2 far away from the stator core section 1 are provided with an air inlet channel 3, and an air channel is provided between each stator core section and each rotor core section, and the air inlet channel 3 is arranged between each stator core section and each rotor core section. Wind pressure elements 6 are arranged on the air passage, and the width of the radial air passage 4 between each rotor core segment is greater than the width of the radial air passage 5 between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com