Thermal deposition apparatus

A thermal evaporation and evaporation technology, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of large evaporation deviation, difficulty in uniform evaporation, and reduced evaporation quality, etc. The effect of reducing impurity content, increasing use efficiency and improving evaporation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the preferred embodiments according to the present invention will be described in detail with reference to the drawings. Prior to this, the terms or words used in this specification and claims are not limitedly interpreted as general or prior meanings, but should be interpreted as meanings and concepts consistent with the technical idea of the present invention.

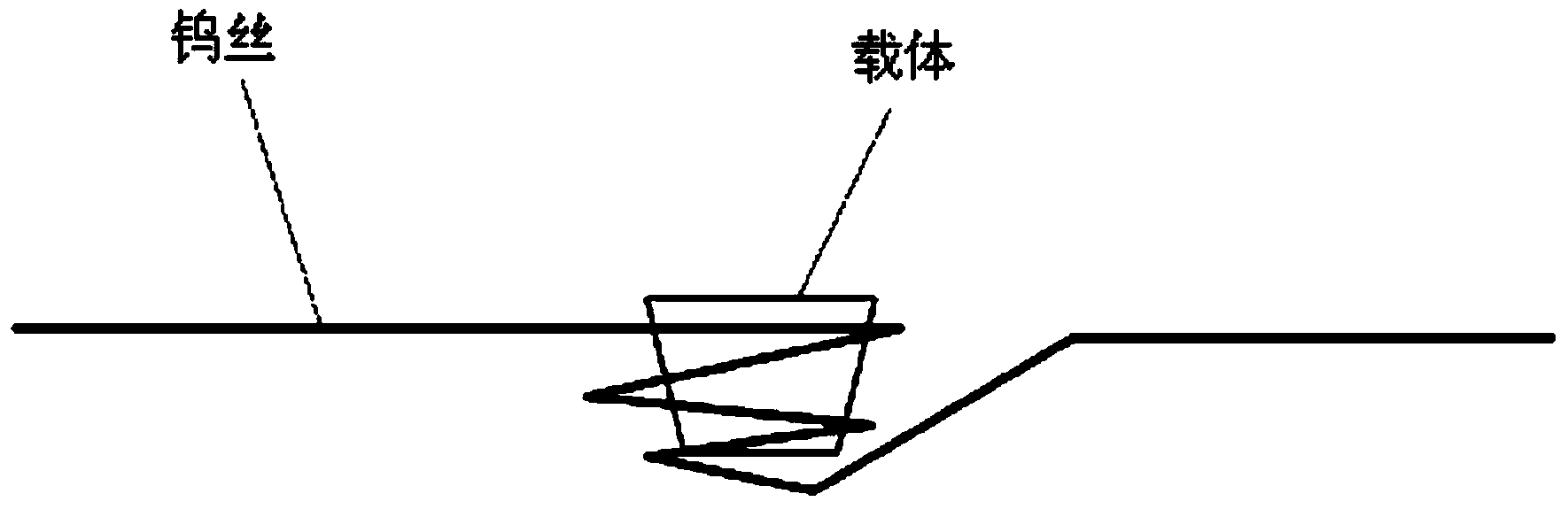

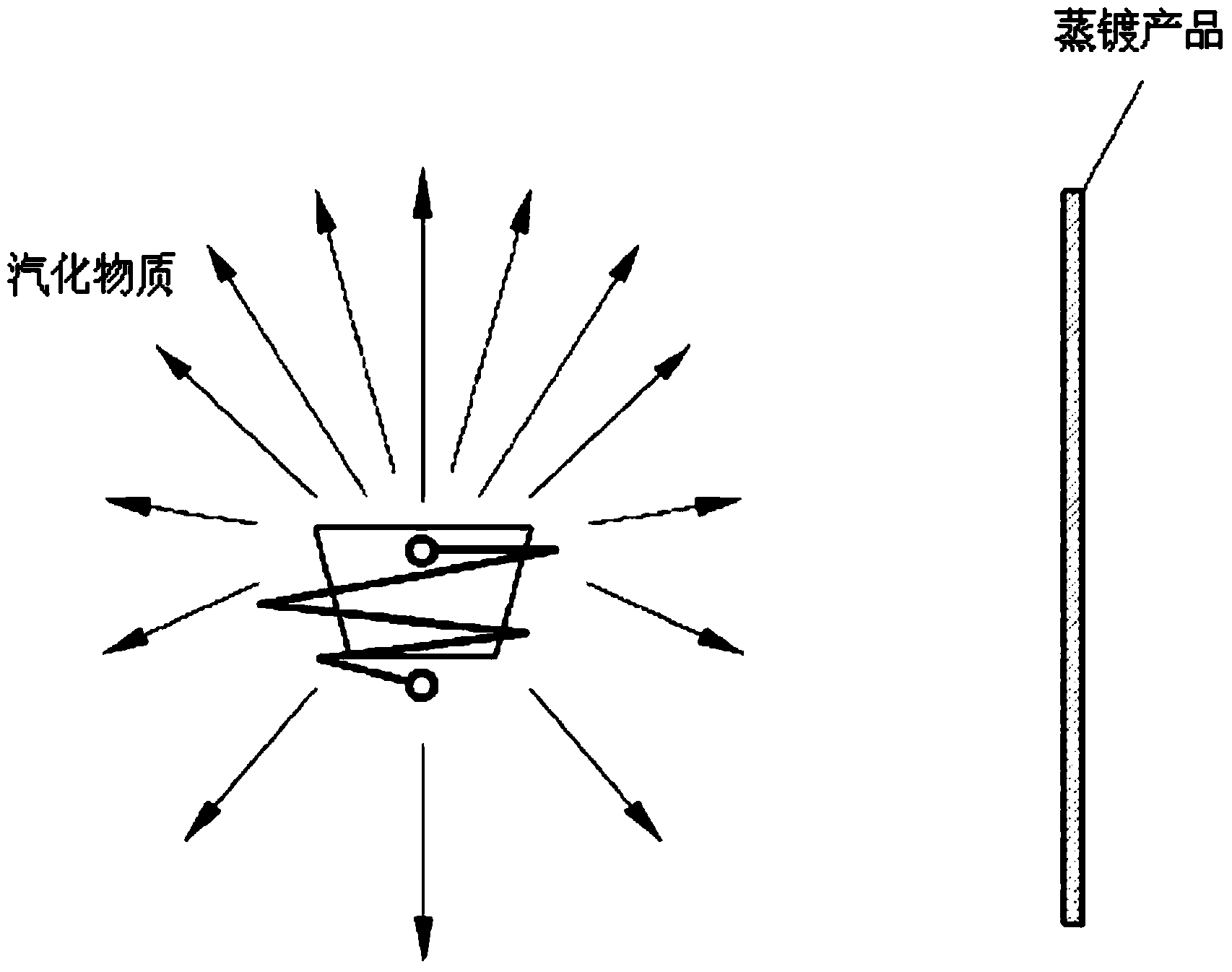

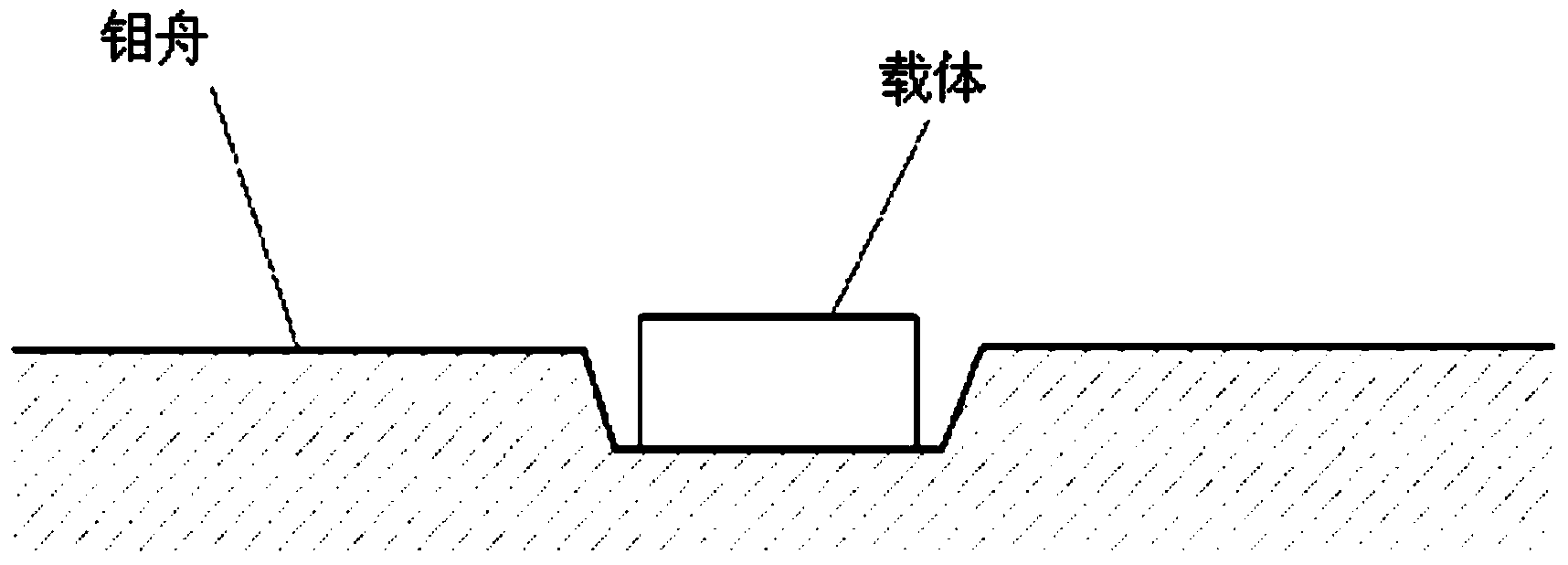

[0022] The present invention relates to a thermal vapor deposition device, which includes: a carrier, which contains the existing vapor deposition material; a heater, which heats the carrier containing the vapor deposition material; a jig, which is used to carry equipment to form It is movable in front of the carrier. Wherein, the heater is a plate-shaped metal heater, which is arranged parallel to the idle axis of the equipment, and the carrier is located in front of the plate-shaped metal heater.

[0023] In other words, as shown in Figures 3 to 5, the thermal vapor deposition device of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com