Self-cleaning stain-resistant oil fume and dust fog air filtering and purifying equipment

A technology for air filtration and purification equipment, which is applied to chemical instruments and methods, separation of dispersed particles, combined devices, etc., which can solve the problems of wasting time and cost for cleaning filter material components, wasting water sources and costs for cleaning components, and poor filtration efficiency, etc. , to achieve long-term stability of filtration efficiency, avoiding water resource costs, and eliminating time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

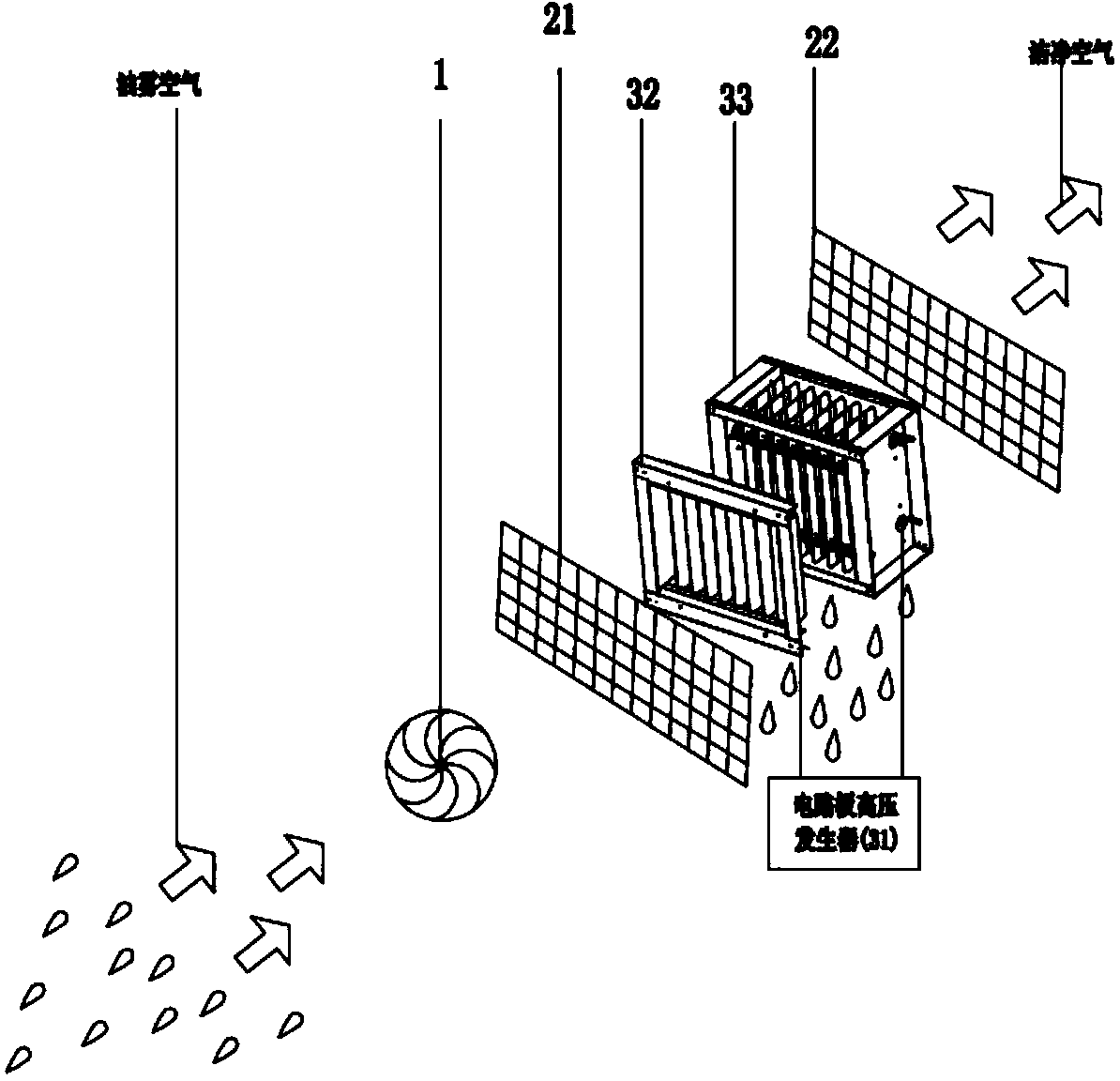

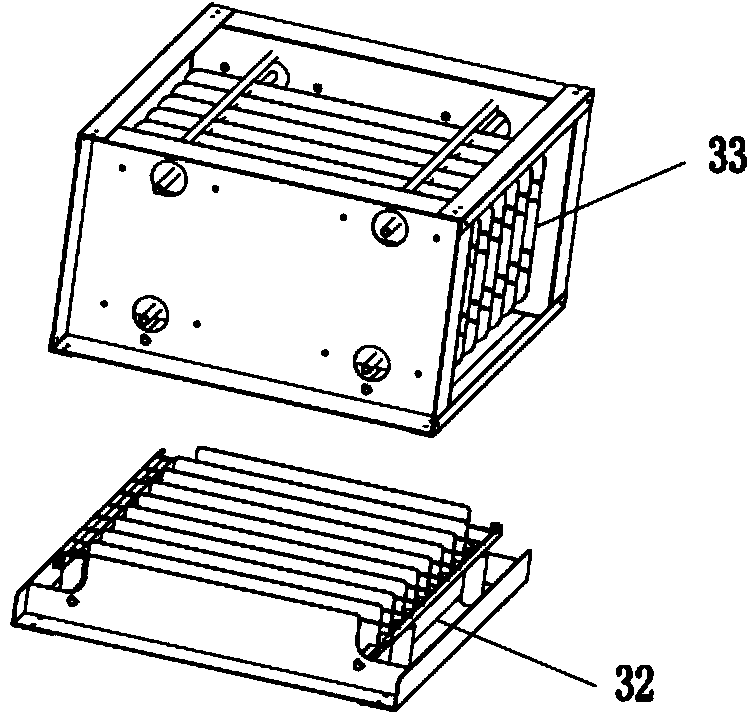

[0020] like figure 1 As shown, the fan module 1 is used to provide air power for extracting oil smoke and dust; the filtration and separation module 2 includes: a pre-screen filter 21, which is arranged at the air inlet of the fan module 1, and is used to filter and separate the fan The oil, smoke, dust, and larger particles in the mist air sucked by the module 1; the rear mesh filter 22 is arranged at the air outlet of the fan module 1 to further filter the air of oil, smoke, dust, and mist; the ionization adsorption area 3, It is arranged between the pre-screen filter screen 21 and the rear screen filter screen 22, including an ionization device 32 and an adsorption device 33. The ionization device 32 includes several conductive plates or wires and several parallel It is composed of a grounding conductive plate connected between the conductive plates, the conductive plate can be an electrode wire, and the conductive or wire plate has an oil-repellent and hydrophobic structur...

Embodiment 2

[0033] According to the different requirements of the air volume and the different filtering effects, the difference from Embodiment 1 is that the front mesh filter 21 is arranged at the air outlet of the fan module 1, and the rear mesh filter 22 is arranged at the fan module. The air inlet of 1 and the ionization adsorption area 3 are arranged between the pre-screen filter 21 and the rear filter 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com