Bactericidal filter layer for water pump and manufacturing process of bactericidal filter layer for water pump

A technology of manufacturing process and filter layer, applied in the field of sterilizing filter layer for water pumps and its manufacturing process, can solve problems such as difficult maintenance of equipment, complex design structure, complicated replacement of piping system, etc., achieve excellent adsorption filtration and improve filtration effect , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

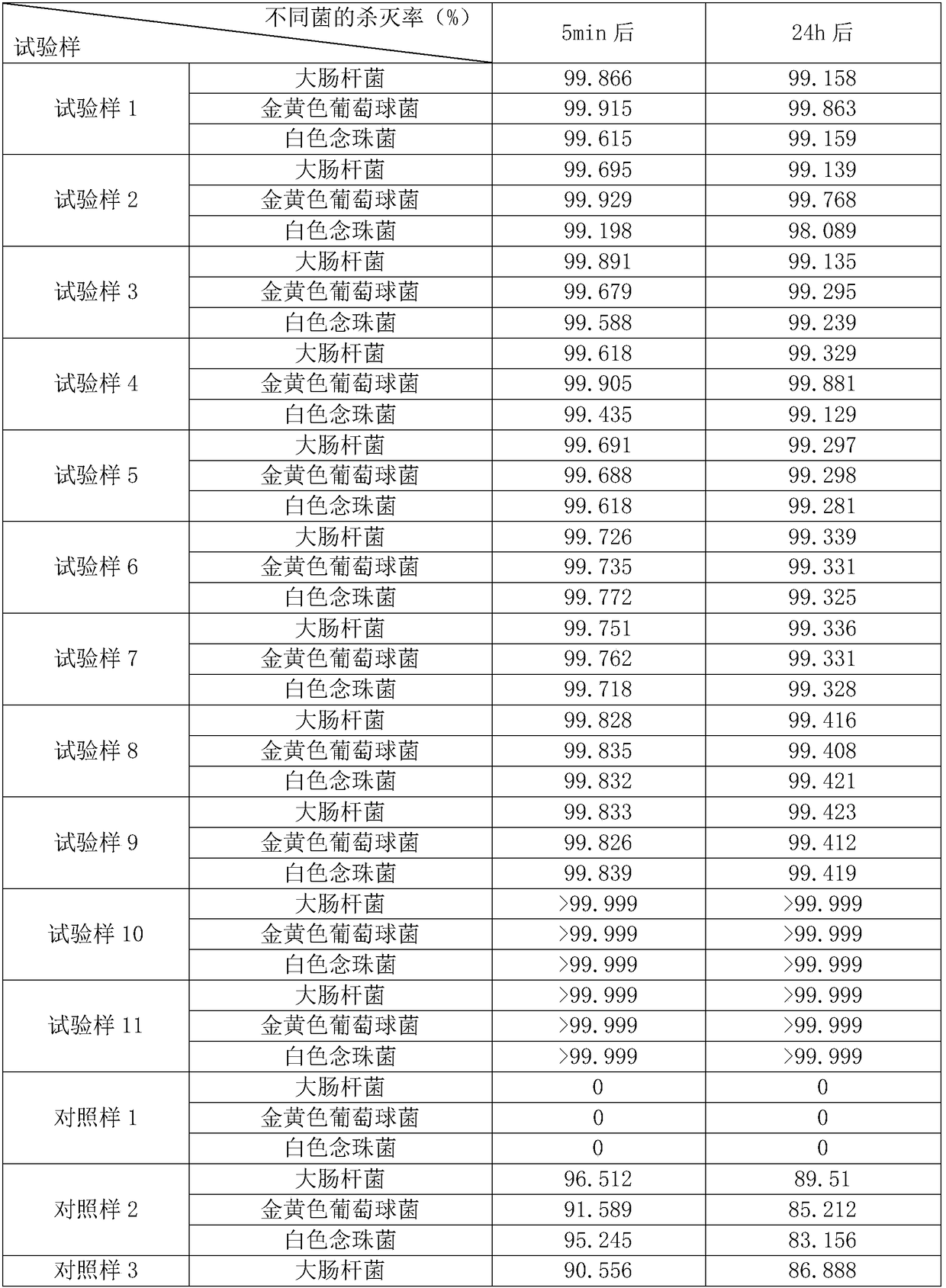

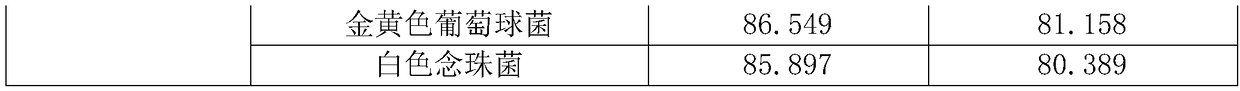

Examples

Embodiment 1

[0041] Example 1: A sterilizing filter layer for a water pump, the elongation at break of the filter layer is 40%, and the density is 12.5kg / m 3 .

[0042] And the sterilization filter layer for water pump is prepared by the following steps:

[0043] Step 1, disperse and manufacture polyester fibers with a strength of 3.5 g / denier to obtain a filter layer;

[0044] In step 2, the bactericide and ethanol are fully mixed at a weight ratio of 1: 5-5.5 to form a bactericide mixed solution;

[0045] In step 3, the filter layer obtained in step 1 is immersed in the bactericide mixture obtained in step 2 according to the standard of adding 22-24L of the bactericide mixture to the filter layer per cubic meter, immersed for 5 minutes, and the filter layer is taken out. , fully dried to obtain a sterilization filter layer for water pumps.

[0046] Wherein, the bactericide is composed of dichlorophenoxychlorophenol and sorbic acid with a weight ratio of 2:1.

Embodiment 2

[0047] Example 2: A sterilizing filter layer for a water pump, the difference from Example 1 is that the strength of the polyester fiber is 5.5 g / denier, the elongation at break of the filter layer is 25%, and the density is 13 kg / m 3 .

Embodiment 3

[0048] Example 3: A sterilizing filter layer for a water pump, the difference from Example 1 is that the strength of the polyester fiber is 4 g / denier, the elongation at break of the filter layer is 35%, and the density is 12.8 kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com