Environment-friendly and energy-saving eddy crusher

An energy-saving, pulverizer technology, used in grain processing and other directions, can solve the problems of high price, very high requirements on the strength of the impact tooth plate, and complex structure of the jet pulverizer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

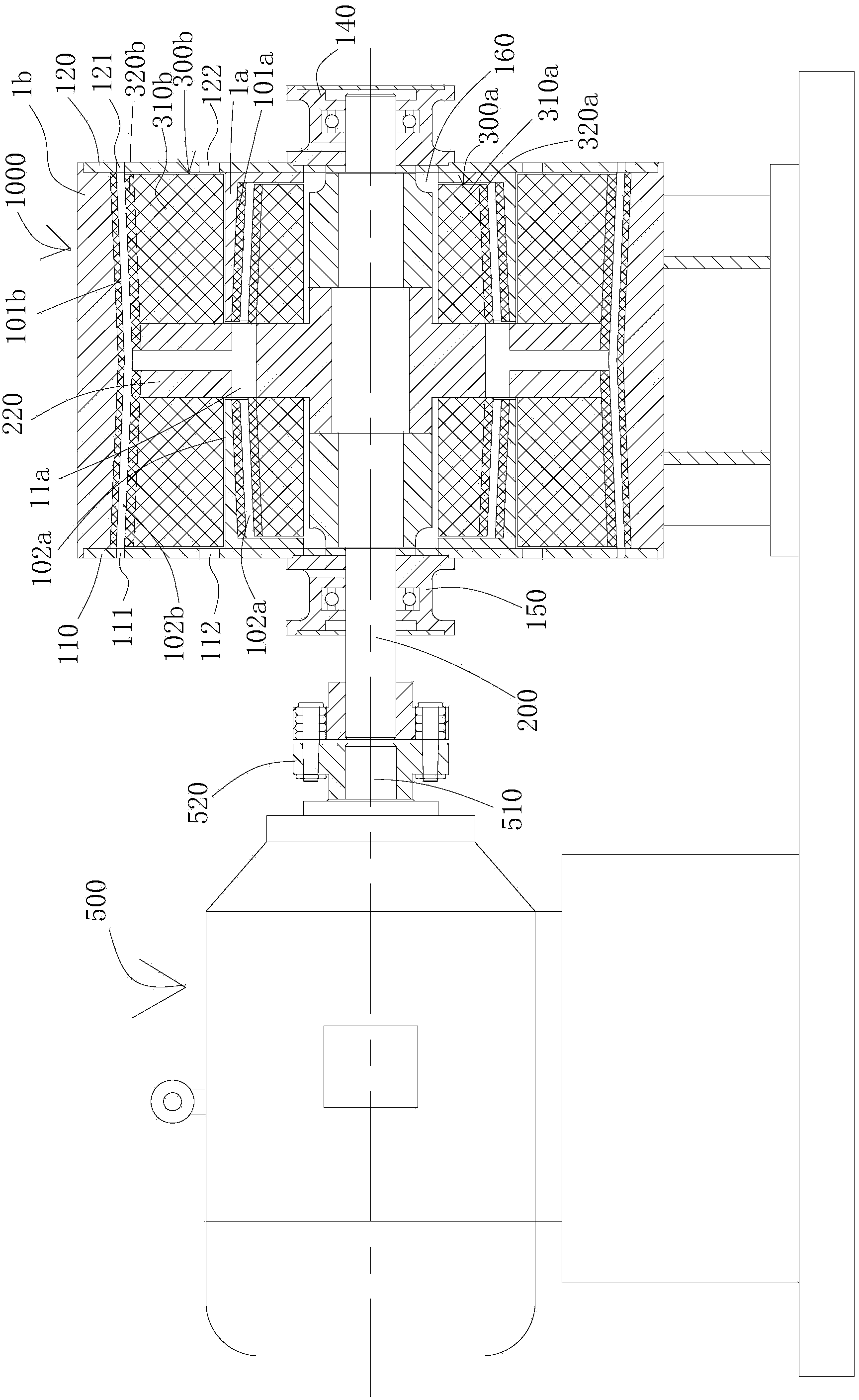

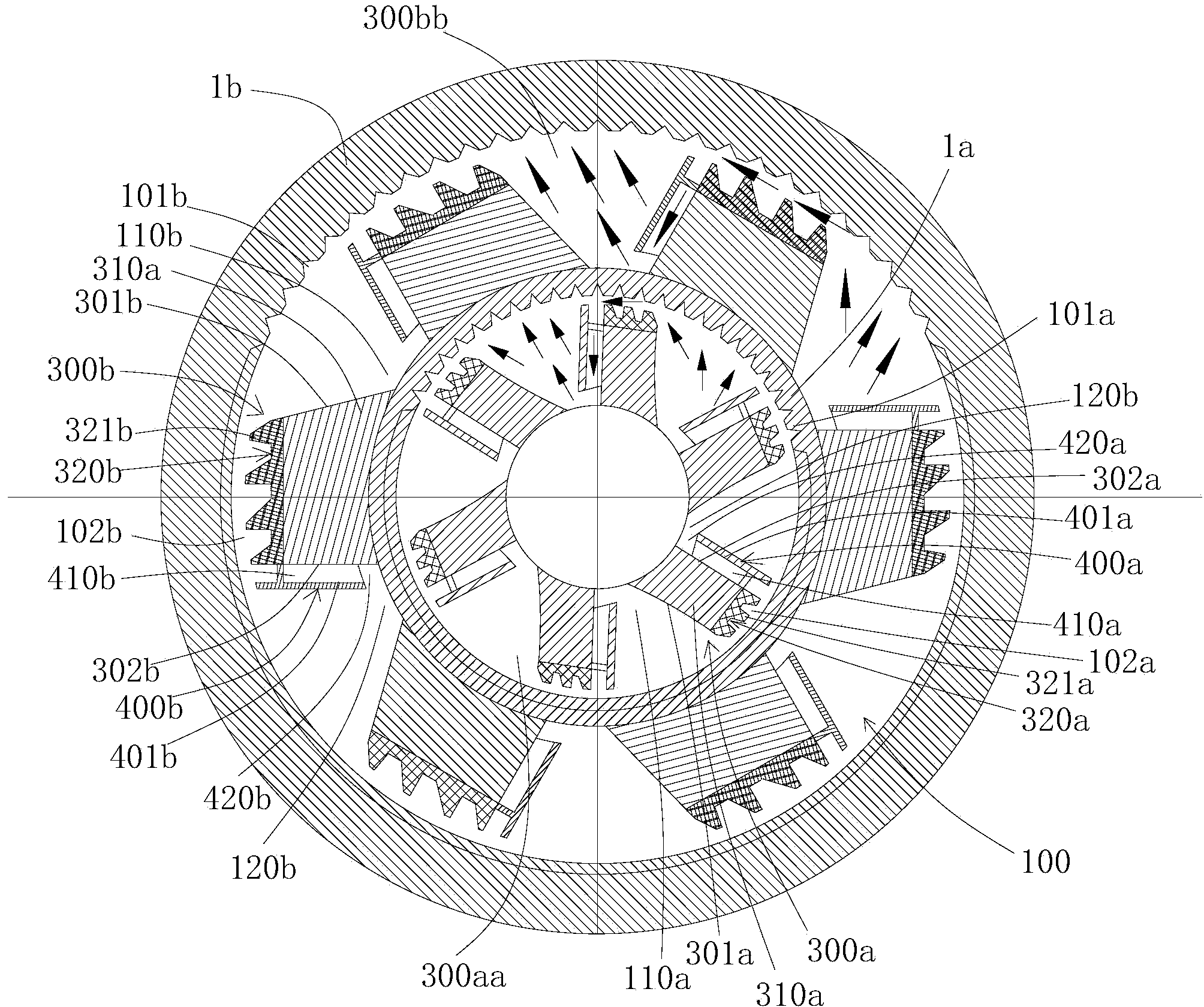

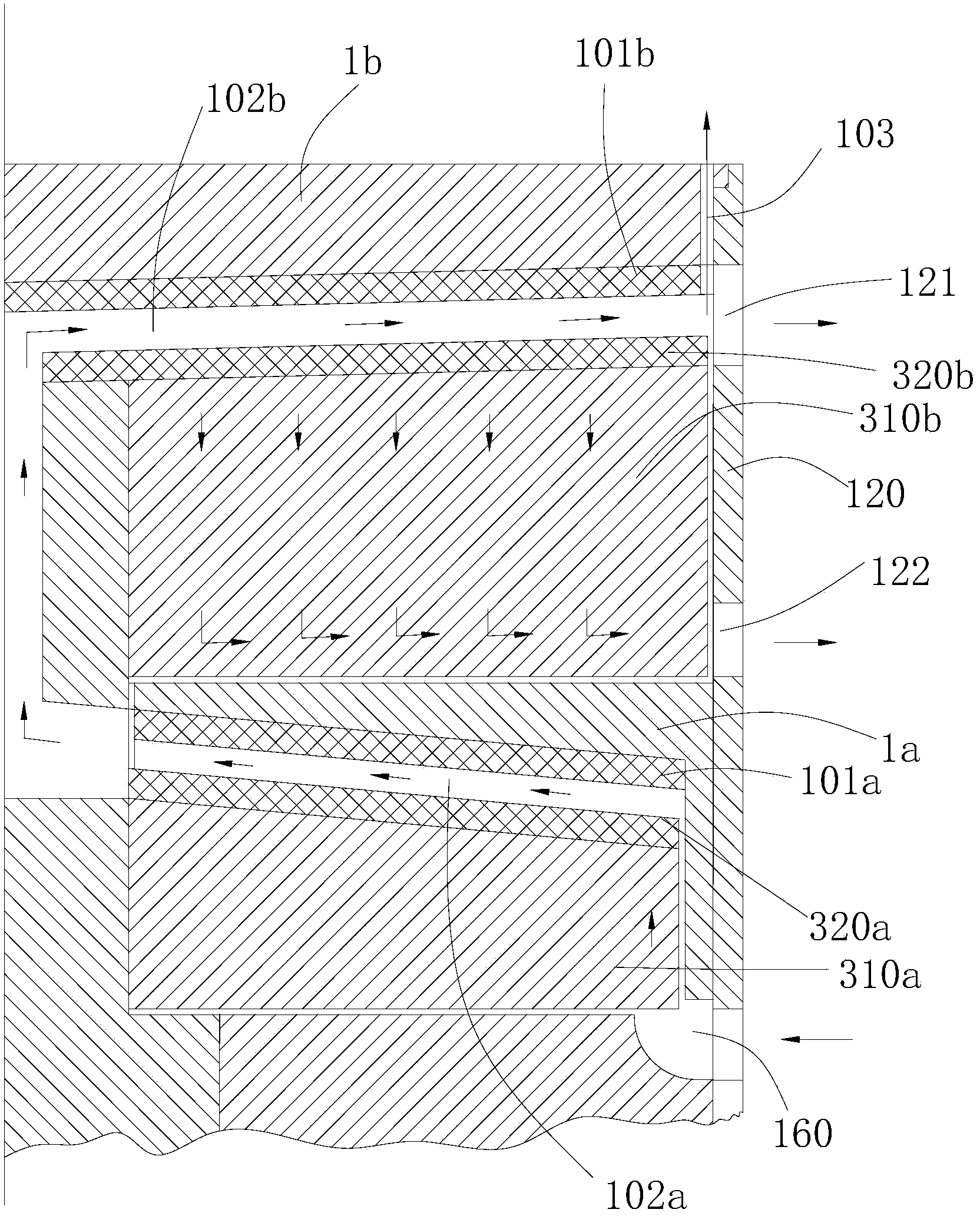

[0027] see figure 1 and figure 2 As shown, the environmental protection and energy-saving vortex pulverizer includes a variable speed motor 500 and a pulverization device 1000, and the pulverization device 1000 includes an inner cylinder 1a, an outer cylinder 1b, a rotor shaft 200, a wheel disc 220 installed on the rotor shaft 200, and six inner cylinders. Grinding block 300a, six outer grinding blocks 300b.

[0028] The inner cylinder 1a is coaxially fixed in the outer cylinder 1b, and the middle part of the inner cylinder 1a is provided with an annular groove 11a for the wheel disc 220 to protrude from. The front end and rear end of the outer cylinder 1b are respectively provided with a front density cover 110 and a rear sealing cover 120, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com