A method of medium and high frequency induction heating radial forging forming screw

A high-frequency induction heating and radial forging technology, applied in metal processing equipment and other directions, can solve the problem of forming large-diameter lead screws without warm forming technology using radial forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

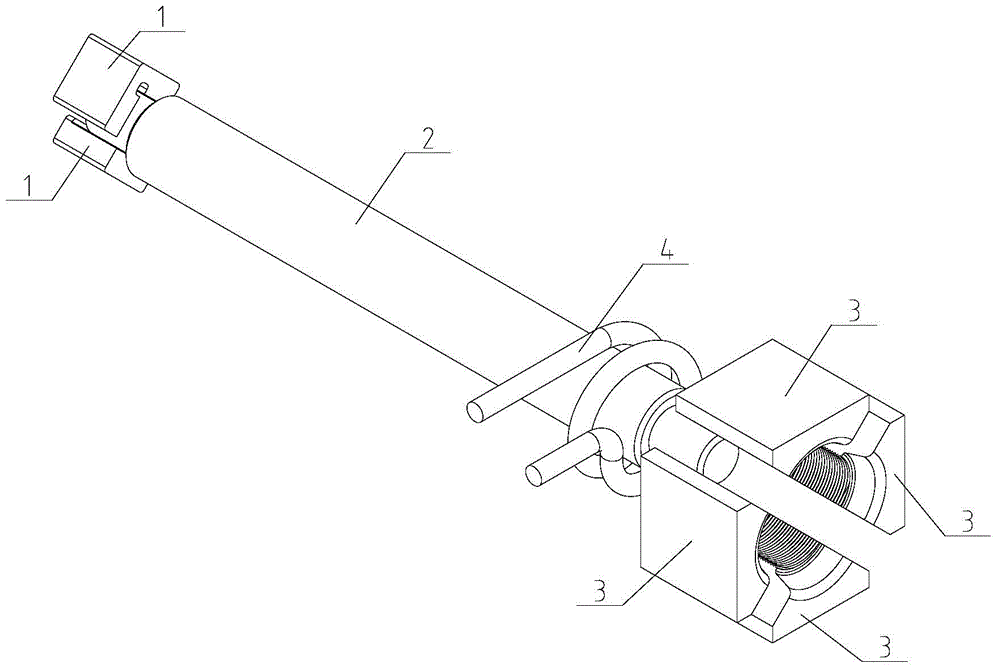

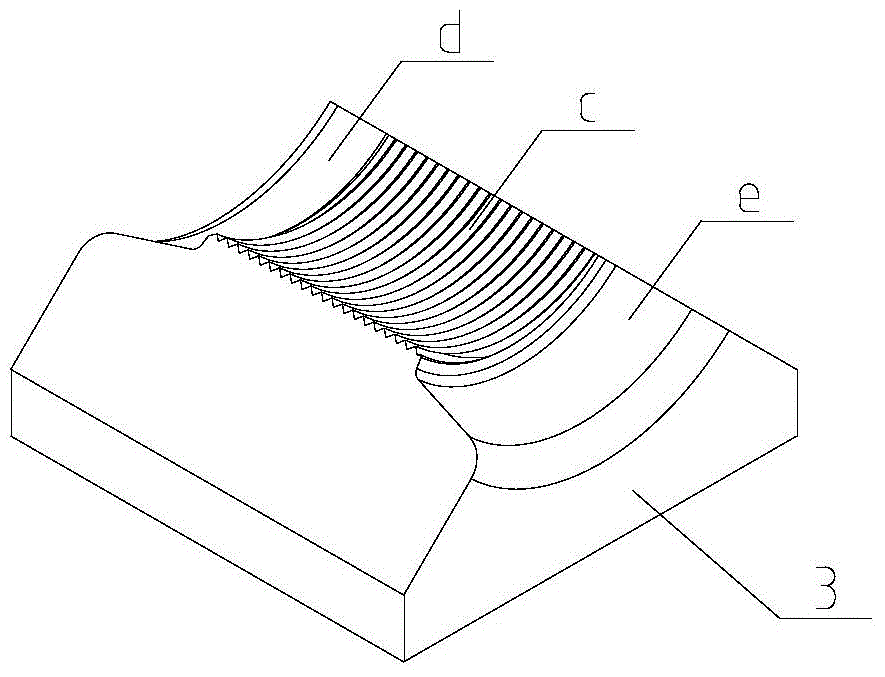

[0047] In this example, four hammerheads are used, and the four hammerheads are arrayed at equal intervals along the axis of the workpiece in space, and the material of the lead screw is 42CrMo high-strength steel.

[0048] A method for radially forging and forming a lead screw by medium and high frequency induction heating, comprising the following steps:

[0049] Step 1, clamping the workpiece 2, one end of the workpiece 2 is clamped by the first manipulator 1;

[0050]Step 2, locally heating the surface of the end area of the formed screw section on the workpiece 2, specifically:

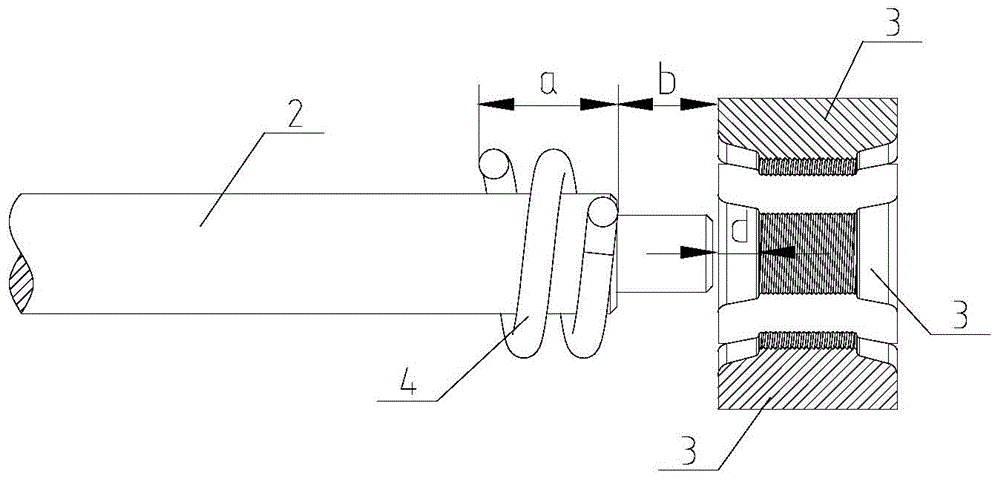

[0051] 2.1. Reference figure 1 , the workpiece 2 is fed in the direction of the radial forging hammer head 3, and the forming screw section on the workpiece 2 enters the medium-high frequency induction heater 4, and the medium-high frequency induction heater 4 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com