Welding method of stainless steel plate

A technology of stainless steel plate and welding method, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of flexible welding method, simple operation and shortened maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The welding method of the stainless steel plate of the present invention will be described in detail below.

[0026] The purpose of the present invention is to provide a welding method for stainless steel plates. This welding method is easy to operate and is suitable for welding during on-site maintenance.

[0027] According to the welding method of stainless steel plates of the present invention, the method comprises: a step of cleaning the area to be welded of the stainless steel plates; a step of pairing the cleaned stainless steel plates; lapping the paired stainless steel plates The step of welding the joint; the step of welding the end joint between the edge of the welded stainless steel plate and the end of the steel pipe; the step of closing the arc for each section of the weld; Steps for water cooling.

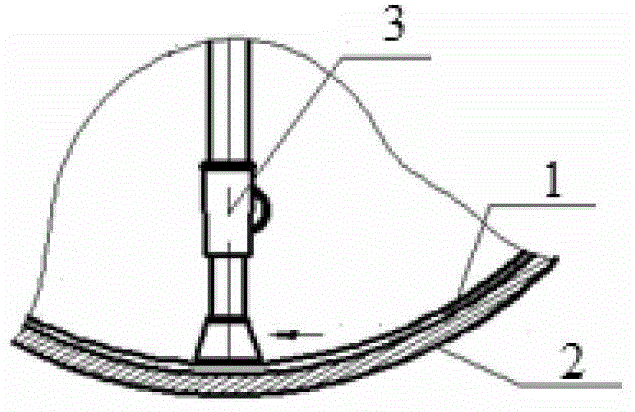

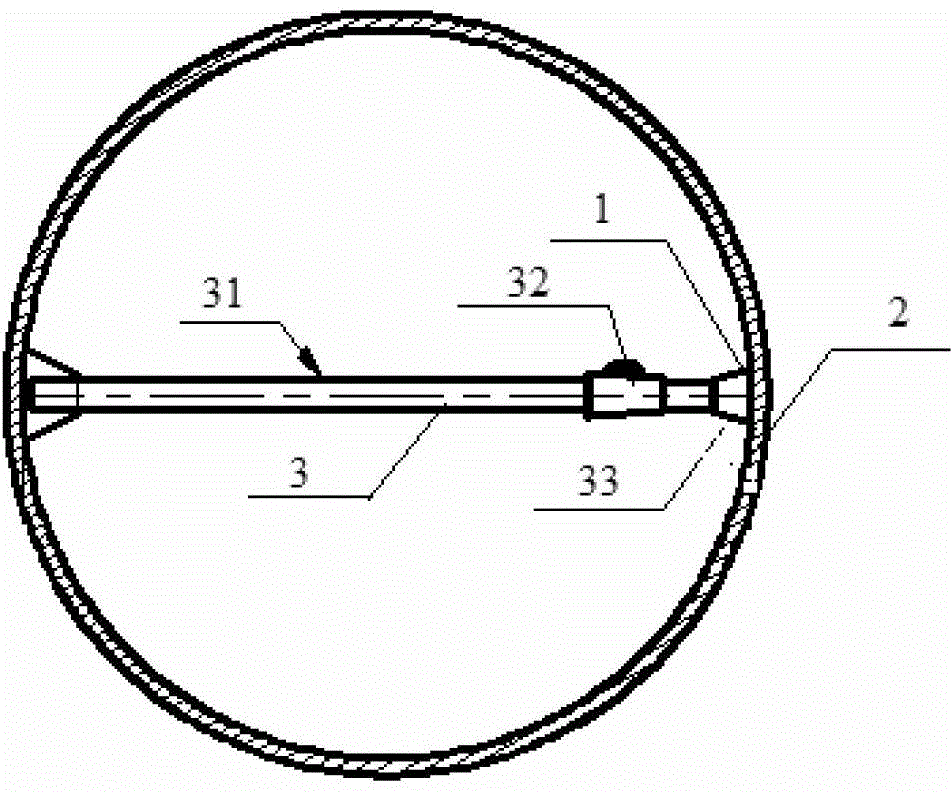

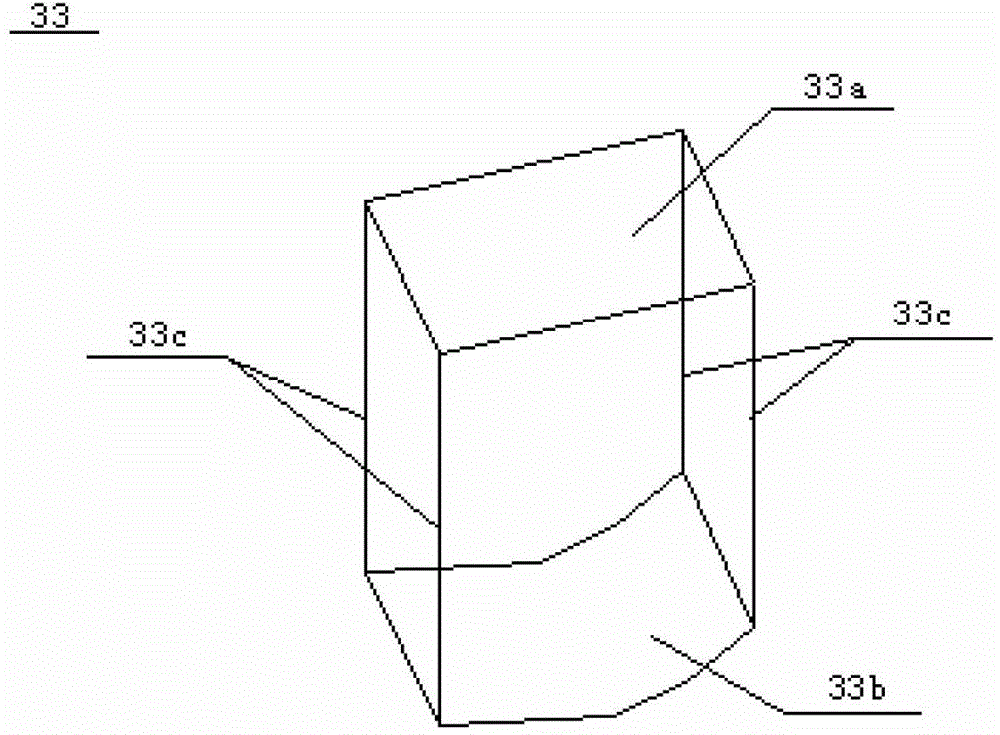

[0028] The following will refer to figure 1 The welding method of the stainless steel plate of the present invention is described in detail to FIG. 5 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com