Fixing device for damageable workpieces

A technology for fixing devices and workpieces, applied in positioning devices, clamping devices, metal processing machinery parts, etc., can solve problems such as inability to fix, deform or damage, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

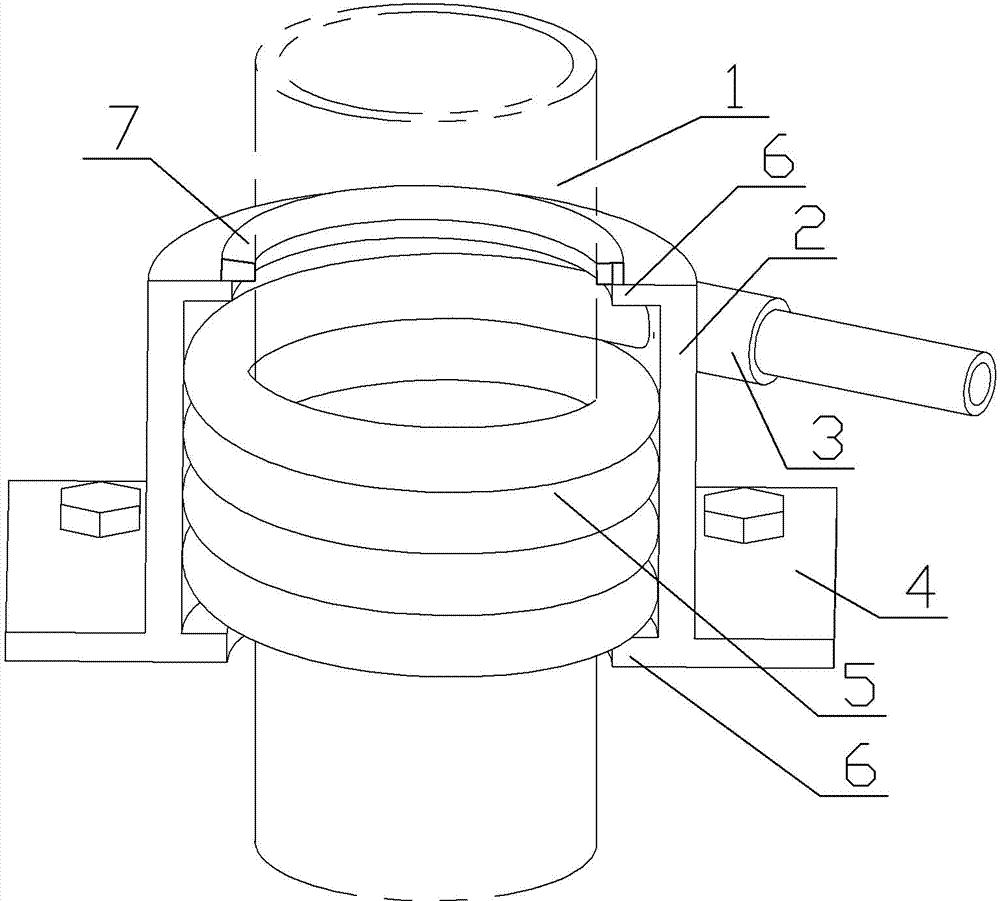

[0011] For the convenience of description, the "upper" and "lower" referred to in the following are respectively related to the attached figure 1 The up and down directions are the same, but it does not limit the structure of the present invention.

[0012] Below in conjunction with accompanying drawing and embodiment technical solution of the present invention is described in further detail:

[0013] like figure 1 The shown fastening device for vulnerable workpieces includes a hose 5 and a hose holder 2, which is a cylindrical shell. One end of the hose 5 is a closed structure, and the other end is an open structure; the hose 5 is placed in a spiral shape and is located inside the hose holder 2 . The upper end of the hose holder 2 is also provided with a boss 6 for limiting the hose 5, and the lower end is provided with a boss 6 and a fixing platform 4 for fixing the hose holder 2; the boss 6, the fixing platform 4 It is integrally constructed with the hose holder 2. A ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com