Multifunctional clamp for industrial robot teaching

An industrial robot and multi-functional technology, applied in the direction of educational appliances, teaching models, manufacturing tools, etc., can solve difficult problems such as practical teaching, and achieve the effect of simple structure, high precision, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

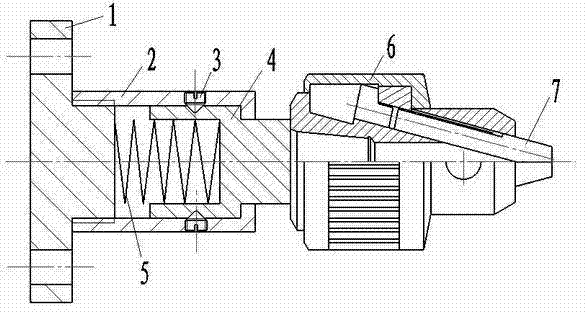

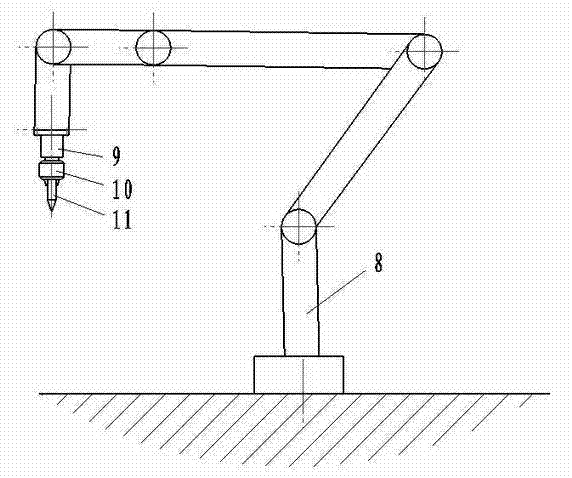

[0009] Embodiments are described in detail with reference to the accompanying drawings. A multifunctional fixture for industrial robot teaching, mainly composed of a clamp body 9 and an automatic centering chuck 10, wherein the clamp body 9 includes a base 1, a sleeve 2, a fastening screw 3, a guide mandrel 4 and a buffer spring 5, The base 1 is threadedly connected with the sleeve 2, which is convenient for disassembly and assembly, and the adjustment of the preload of the buffer spring 5 can be realized by adding washers of different thicknesses. The guide mandrel 4 is arranged in the sleeve 2 and connected with the sleeve. The sleeve 2 is slidingly fitted, and the sleeve 2 is installed with a fastening screw 3 at the position opposite to the guide mandrel 4. After the fastening screw 3 is tightened, the relative fixation of the sleeve 2 and the guide mandrel 4 can be realized. When clamping tools such as threaded screwdrivers, drill bits, taps or reamers, motion and torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com