Electronic hydraulic brake system with mechanical failure protective function

A fail-safe, hydraulic braking technology, applied in hydraulic braking transmissions, brakes, etc., can solve the problems of less braking energy, pipeline leakage, less recoverable energy, etc., and achieve fast response speed and high safety. , the effect of reducing the risk of system failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

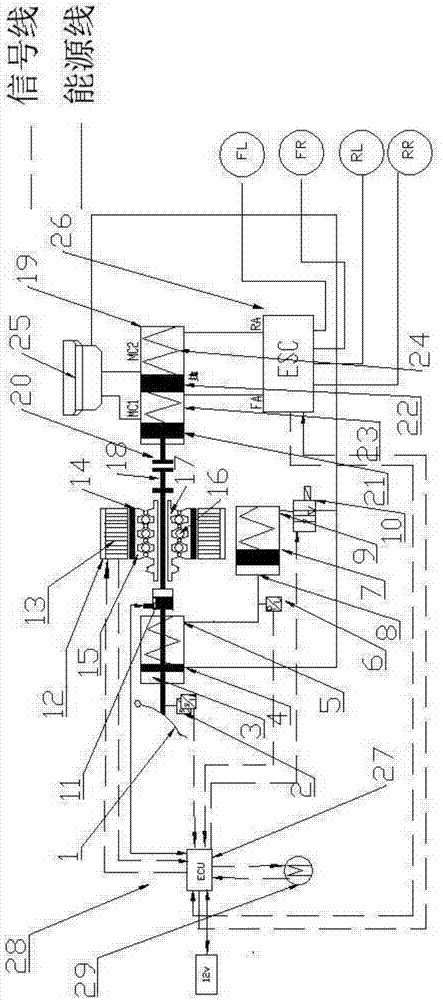

[0026] Such as figure 1 The electro-hydraulic braking system with mechanical failsafe control shown mainly includes a brake pedal 1, a secondary master cylinder 3, a pedal simulator 7, a mechanical failsafe device 11, a motor 12, a motor stator 13, a motor rotor 14, a wire Rod nut 15, ball 16, screw rod 17, linear motion mechanism push rod 18, master cylinder 19, pedal displacement sensor 2, hydraulic pressure sensor 6, solenoid valve 10.

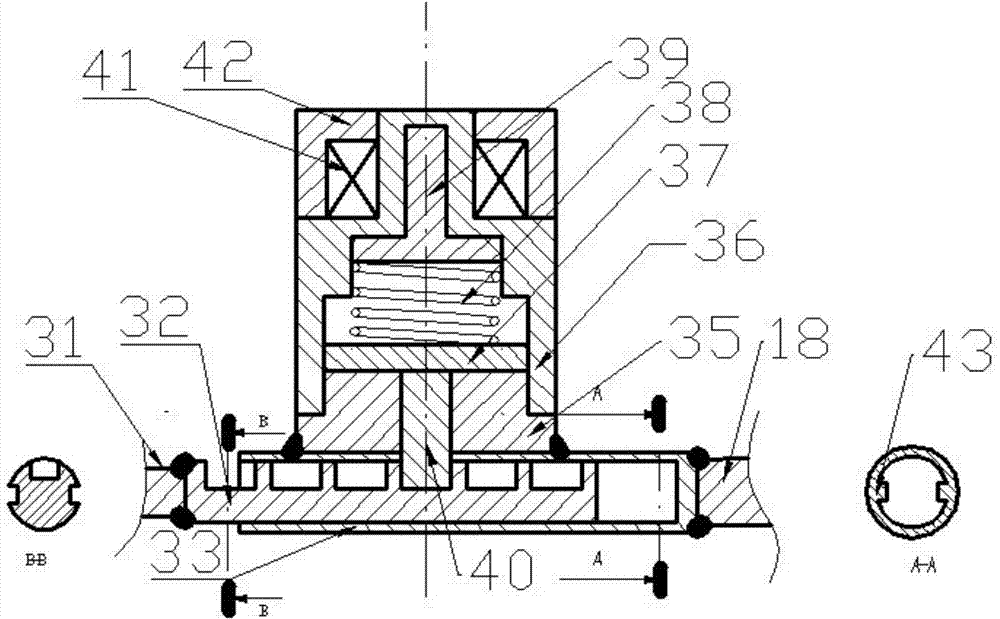

[0027] Such as figure 2 As shown, the mechanical failure protection device 11 mainly includes a bolt lock 32, a bolt lock sleeve 33, a bolt base (aluminum alloy) 35, a bolt shell (aluminum alloy) 36, a moving iron 37, a spring 38, a fixed iron 39, a bolt ( non-ferromagnetic material) 40, electromagnetic coil 41, electromagnetic coil shell (aluminum alloy) 42, latch lock sleeve guide groove 43.

[0028] In this embodiment, the electronically controlled linear motion module includes an electronic control unit 27 , a motor 12 , a motor stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com