Spreader

A spreader and hanger technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of high labor intensity, low production efficiency, cumbersome work, etc., to reduce labor intensity of workers, improve replacement efficiency, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The application will be further elaborated below in conjunction with the accompanying drawings and embodiments.

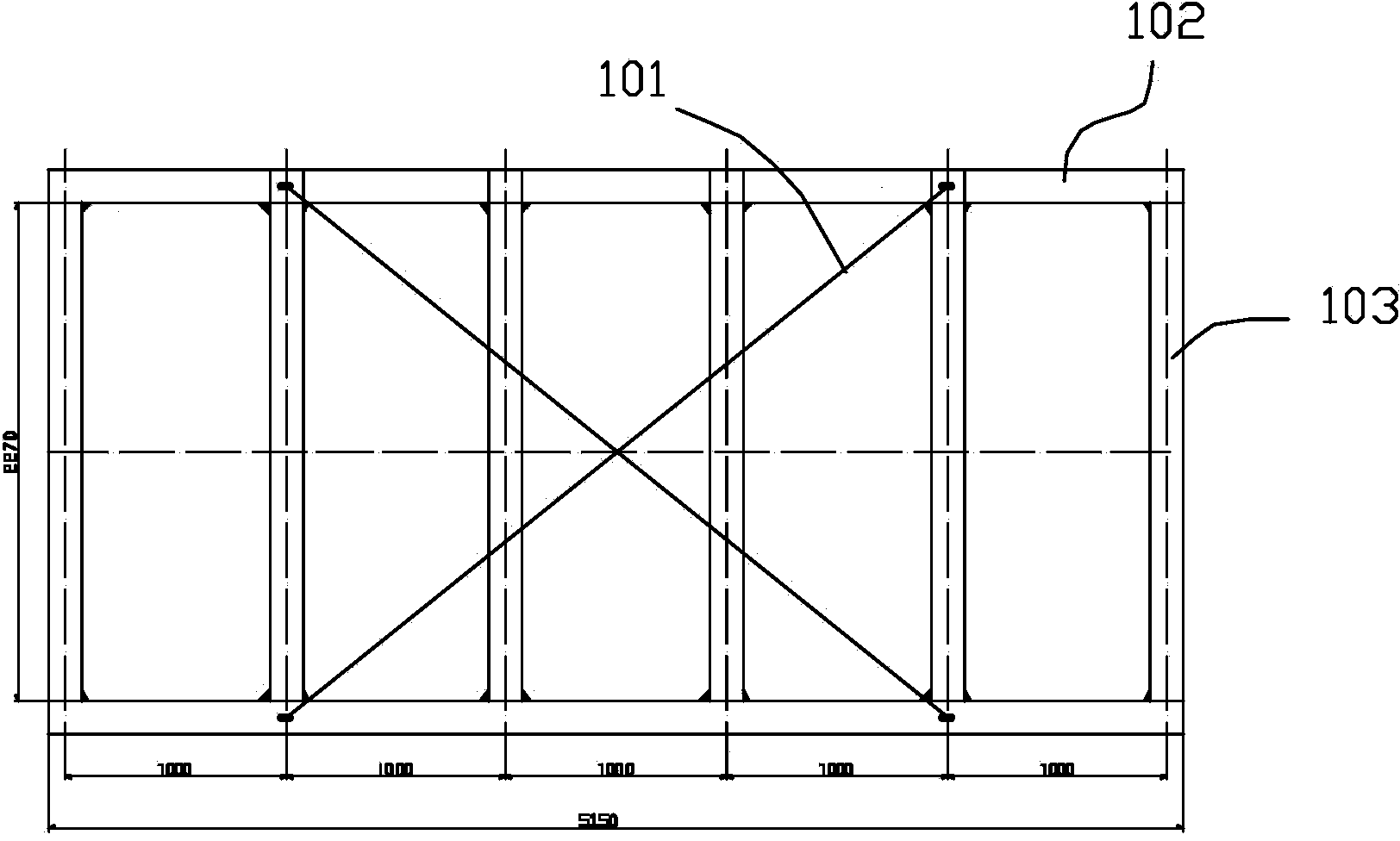

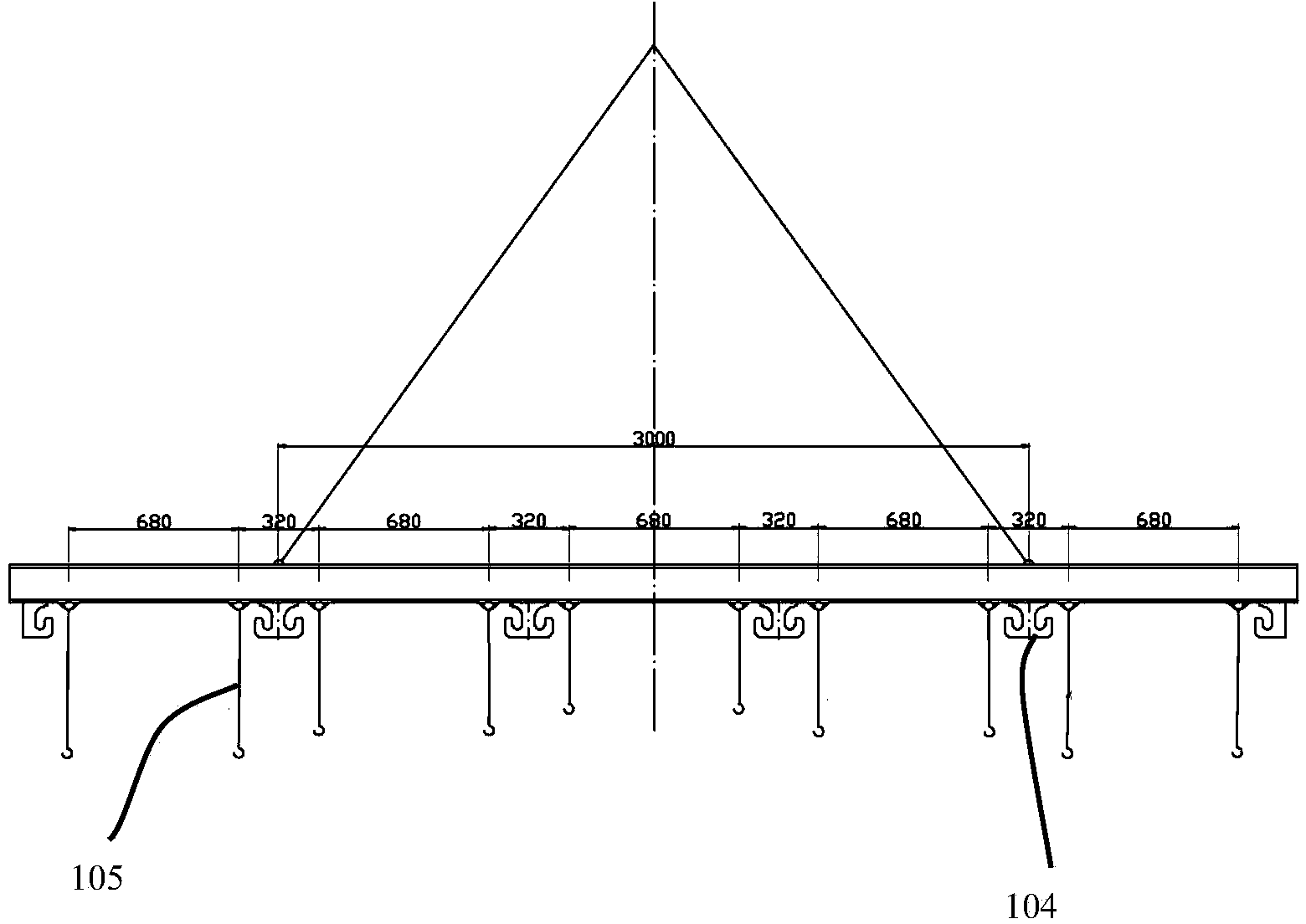

[0029] refer to Figure 1-Figure 5 , a kind of hanger, comprising a grid-type hanger, said grid-type hanger includes two parallel and opposite beams 102 and 6 support beams 103 vertically erected on the beams, between the central axes of two adjacent support beams The distance is 1.0m, each of the beams is provided with 10 suspension chains 105, and the support beams are provided with 4 pairs of hooks 104.

[0030] The hanging chains are evenly distributed along the center of the crossbeam to both sides, and the length of the hanging chains is lengthened sequentially along the center of the crossbeam to both sides.

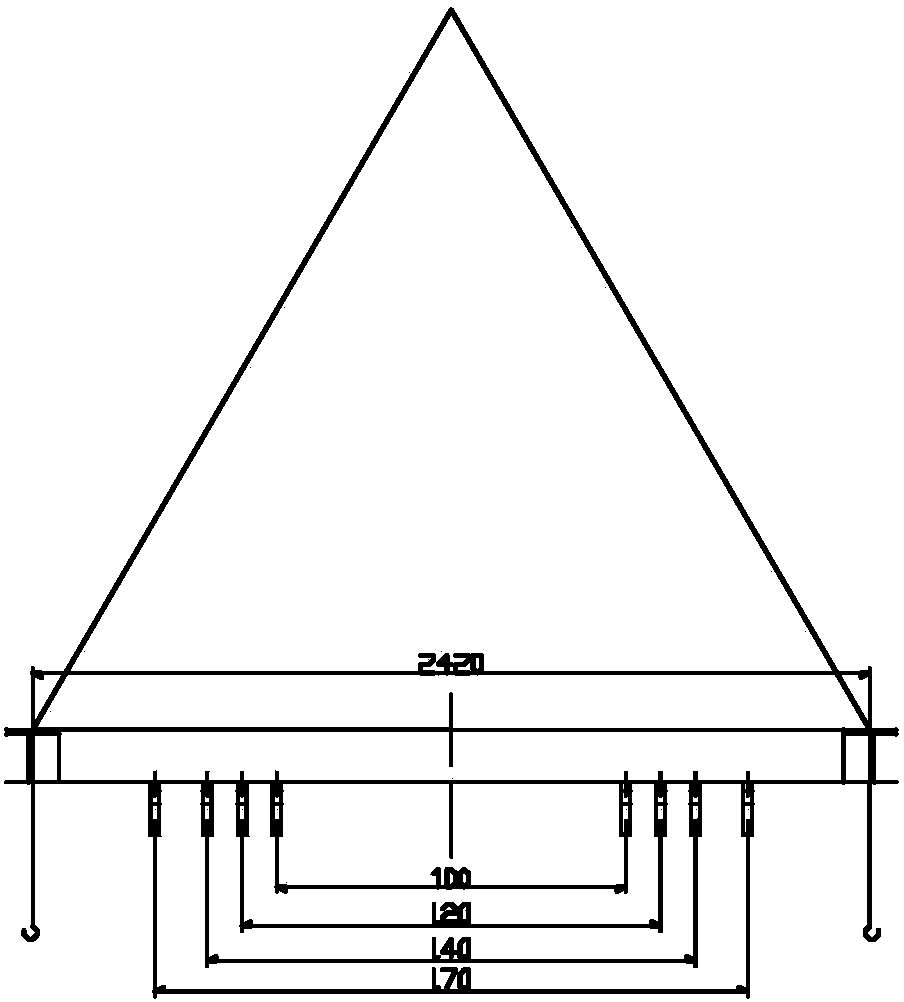

[0031] The hooks on the support beams on both sides of the beam are single hooks, and the hooks on the rest of the support beams are double hooks. The spacing between the 4 pairs of hooks is 0.10m, 0.12m, 0.14m, 0.17m respectively.

[0032] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com