Novel method for recycling ammonia synthesis cold energy in synthetic ammonia system

A technology of cooling capacity recovery and ammonia synthesis, applied in ammonia preparation/separation, etc., can solve the problems of ammonia tank overpressure, liquid ammonia cooling capacity recovery, etc., achieve the effect of reducing ammonia tank pressure, reducing production load, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

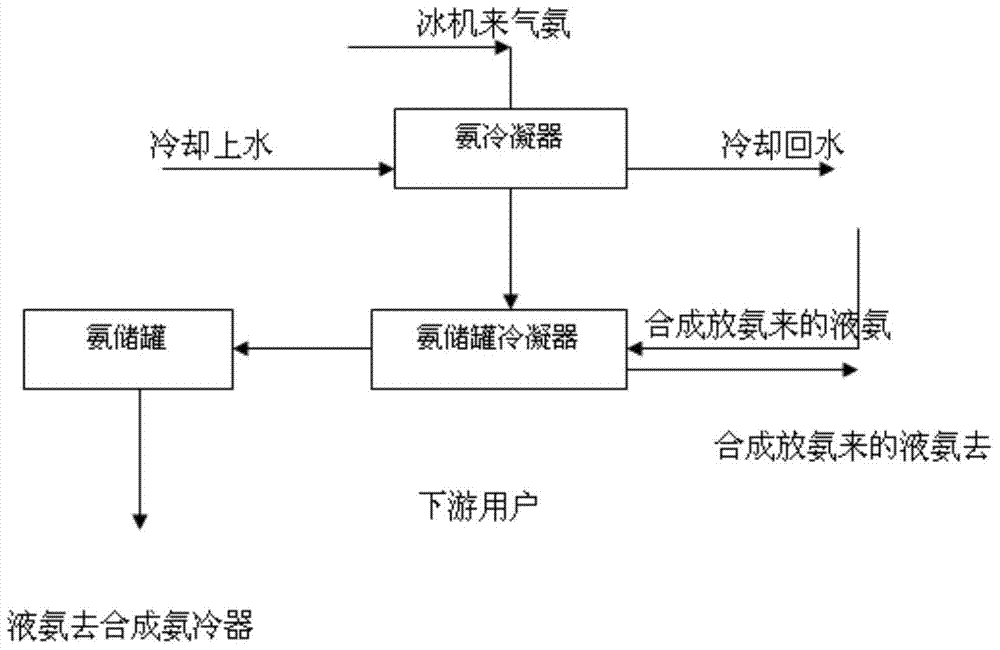

[0028] The specific implementation of the present invention is given below with reference to the accompanying drawings (take a set of 300,000 tons / year synthetic ammonia production equipment as an example):

[0029] Because ammonia synthesis dissolves part of hydrogen and nitrogen in ammonia, the liquid ammonia condensed by the refrigerated condenser also contains part of non-condensable gas. In order to improve the heat exchange effect, the traditional cold recovery process uses the liquid from the ammonia tank outlet of the ice machine. Ammonia exchanges heat with synthetic ammonia and recovers cold energy. The present invention adopts a high-efficiency heat exchanger, changes the previous heat exchange method, and invents a new heat exchange process, which greatly reduces the pressure of the ammonia tank, that is, reduces the pressure at the outlet of the ice machine, thereby reducing the consumption of the ice machine. To achieve the purpose of energy saving. The specific pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com