Concentrating and phosphorus removing method for excess sludge

A technology for excess sludge and sludge concentration, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve complex air flotation concentration equipment, large volume of gravity concentration tank, and cost of dosing chemicals High-level problems, to achieve the effect of low drug price, small footprint, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

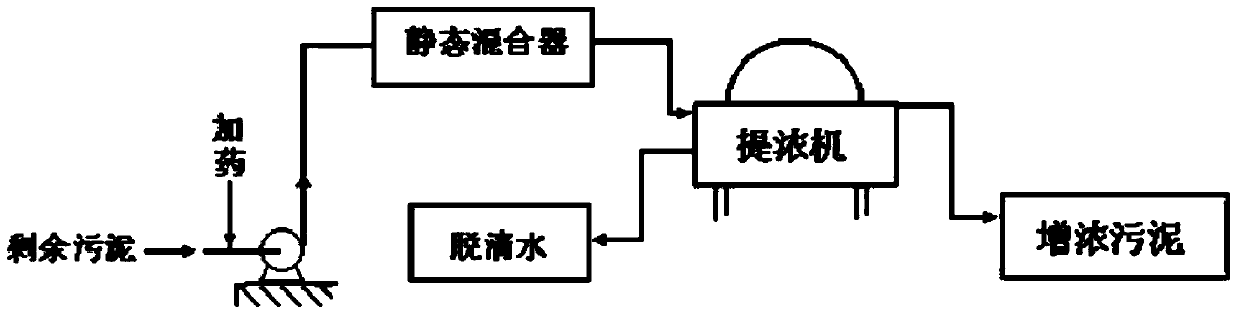

[0024] like figure 1 Shown, the thickening and dephosphorization method of surplus sludge of the present invention comprises the steps:

[0025] (1) The excess sludge to be treated is the activated sludge mixture discharged from the aeration tank with a concentration of 2 to 5 g / L, and the concentration of the sludge in the excess sludge to be treated and the concentration of the sludge after dehydration are detected. Phosphorus content in clean water: Take an appropriate amount of the remaining sludge mixture to be treated, measure the sludge concentration according to the national standard method (GB / T11901-1989) and measure the phosphorus content in the de-cleaned water according to the national standard method (GB11893-89), Calculate the sludge concentration in the remaining sludge to be treated and the phosphorus content in the clean water;

[0026] (2) Put the remaining sludge to be treated and the compound thickening agent together in a stirring device and stir at 300-...

Embodiment 2

[0033] like figure 1 Shown, the thickening and dephosphorization method of surplus sludge of the present invention comprises the steps:

[0034] (1) The excess sludge to be treated is the excess sludge discharged from the aeration tank and discharged through the secondary settling tank with a concentration of 8-9 grams per liter. The sludge concentration and sludge concentration in the excess sludge to be treated are detected. Phosphorus content in clean water after sludge dehydration: take an appropriate amount of residual sludge mixture to be treated, measure the concentration of sludge according to the national standard method (GB / T11901-1989) and measure the concentration in the dewatered water according to the national standard method (GB11893-89). The phosphorus content is calculated to obtain the sludge concentration in the remaining sludge to be treated and the phosphorus content in the clear water;

[0035] (2) Put the remaining sludge to be treated and the compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com