Treatment method for sludge precipitation of ammonia desulfurization solution in iron and steel industry

A technology of ammonia desulfurization and sludge precipitation, which is used in sludge treatment, water/sludge/sewage treatment, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

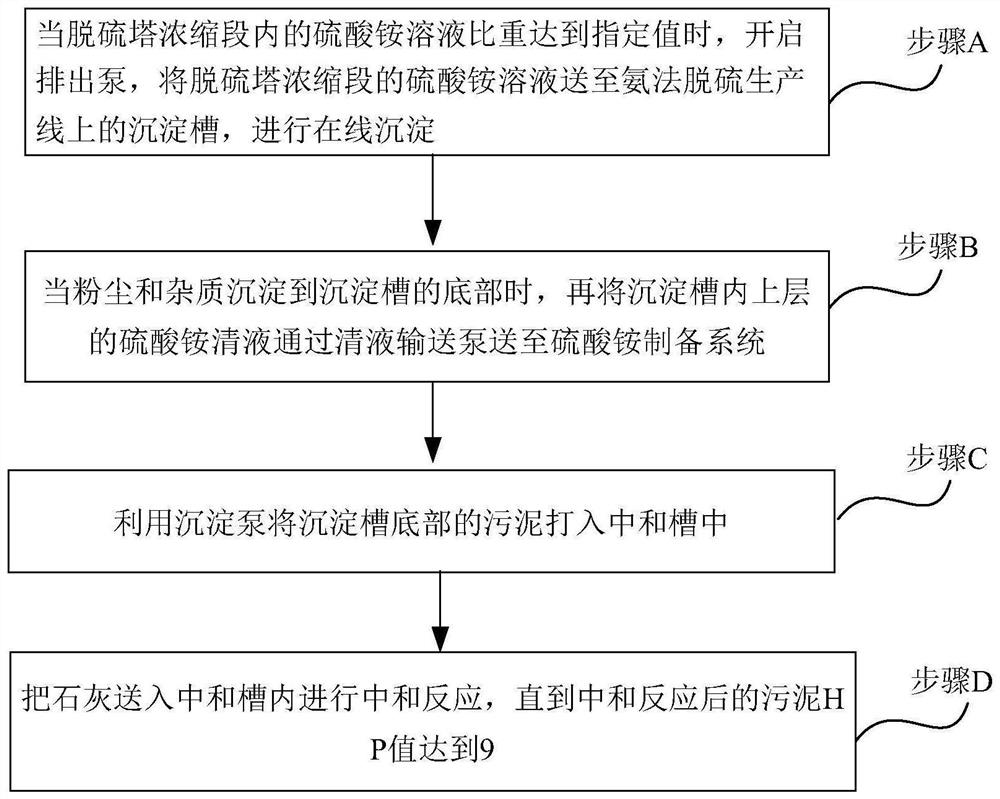

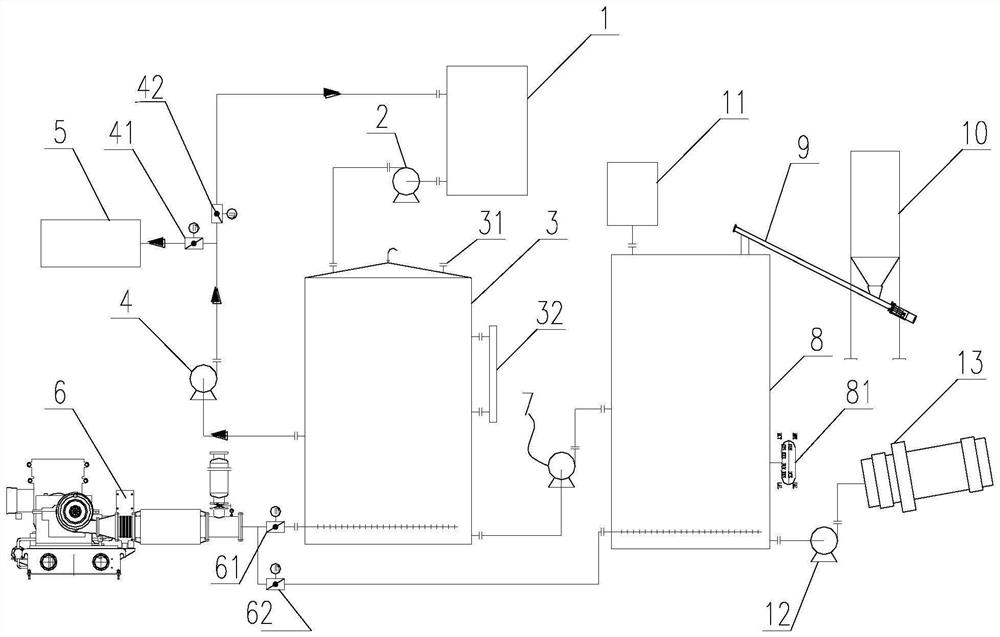

[0052] The invention provides a treatment method for sludge precipitation of ammonia desulfurization solution in iron and steel industry, such as figure 2 When the specific gravity of the ammonium sulfate solution in the concentration section 1 of the desulfurization tower reaches the specified value, turn on the discharge pump 2, and send the ammonium sulfate solution in the concentration section 2 of the desulfurization tower to the precipitation tank 3. Precipitate to the bottom of the precipitation tank 3, and then send the ammonium sulfate clear liquid in the upper layer of the precipitation tank 3 to the ammonium sulfate preparation system through the clear liquid delivery pump 4 (the first electric valve 41 is opened at this time, and the second electric valve 42 is closed) 5 Production of ammonium sulfate fertilizer. When the liquid level of the ammonium sulfate clear liquid in the sedimentation tank 3 (the liquid level signal can be obtained through the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com