Method for preparing high strength microorganism mortar by microorganism generating urease and calcium acetate

A technology of calcium acetate and microorganisms, which is applied in the field of high-strength microbial mortar preparation, can solve the problems of steel bar depassivation, electrochemistry, impact on the durability of concrete structures, corrosion, etc., and achieve the effect of short time, low cost and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

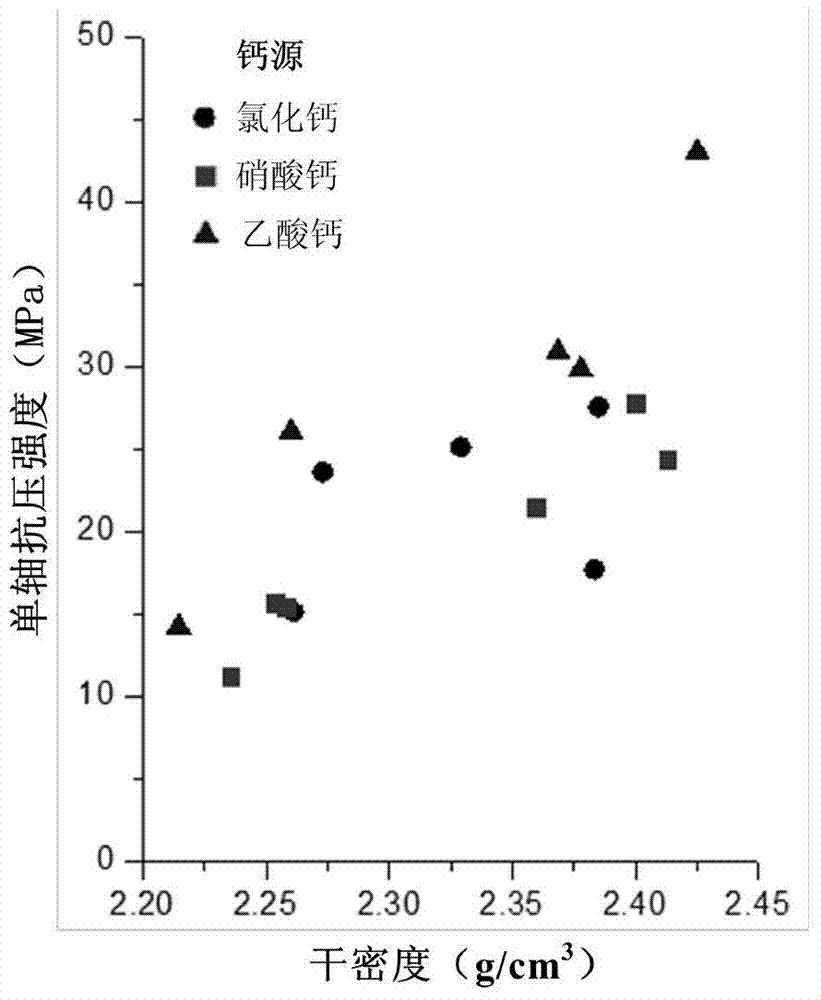

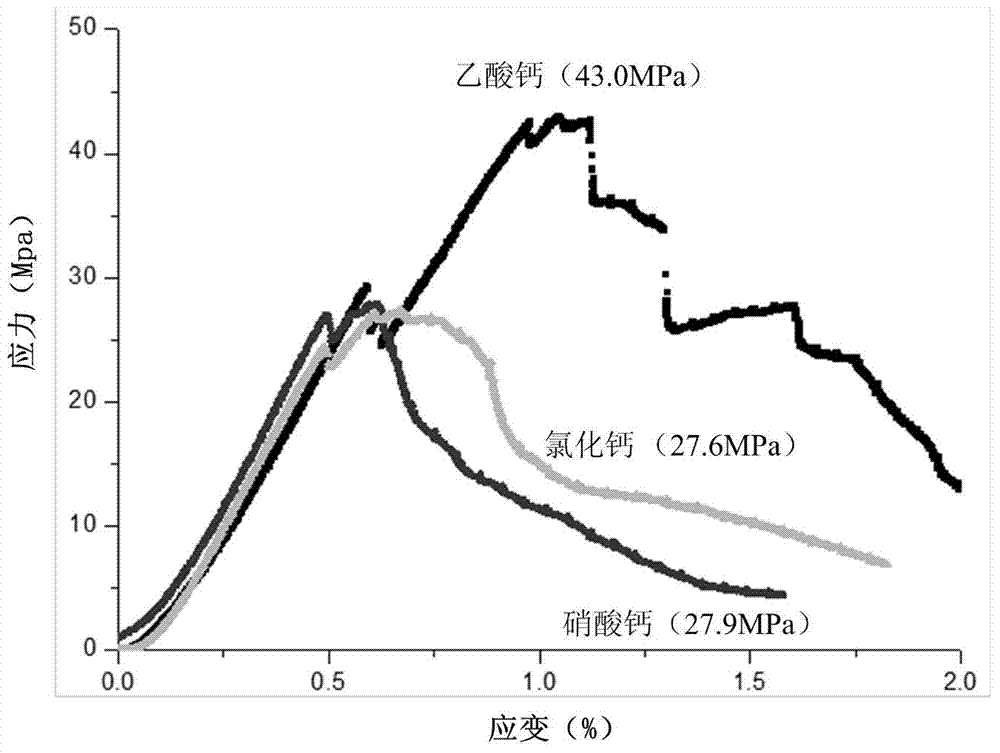

[0031] In this embodiment, the method for preparing high-strength microbial mortar using urease-producing microorganisms and calcium acetate, using calcium acetate as a calcium source, specifically includes the following steps:

[0032] Step 1: prepare fermentation medium: yeast extract 20g / L, sulfuric acid presses 10g / L, pH is 9, 100mL fermentation medium is packed in the 500mL culture bottle and sterilized, will produce urease microorganism Pasteurella sarcina Sporosarcina A single colony of pasteurii was inoculated in the fermentation medium, fermented and cultivated at 30°C, with a rotation speed of 150rpm, and cultured for 18 hours to collect the bacterial liquid;

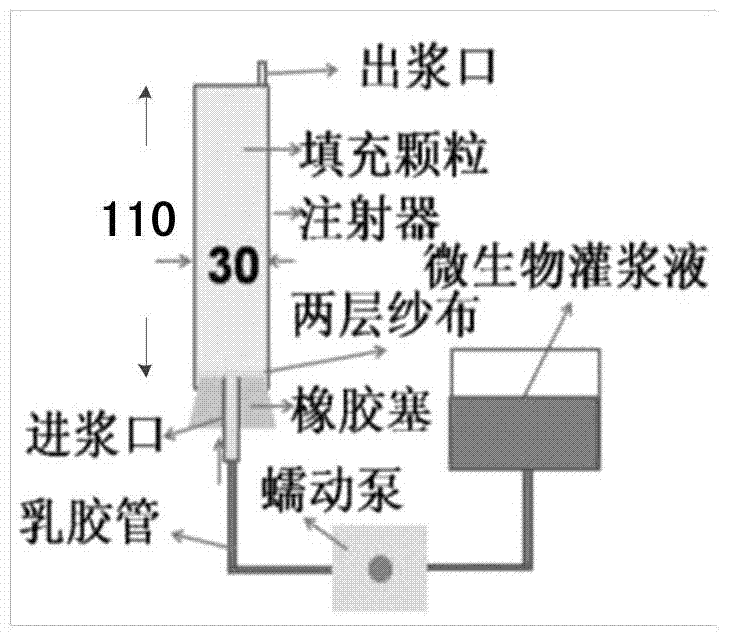

[0033] Step 2: Carry out closed water treatment on the grouting mold, pour sand particles with a particle size of 200-380 microns, close the grouting mold, and reserv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Secant modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com