Capillary crystalline waterproofing agent and preparation method thereof

A technology of infiltrating crystal waterproofing and waterproofing agent, applied in the field of concrete protective agent for construction, can solve problems such as failure to meet impermeability requirements, chloride ion erosion of steel bars, poor impermeability effect, etc., to improve protection and impermeability performance, penetration Strong ability and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

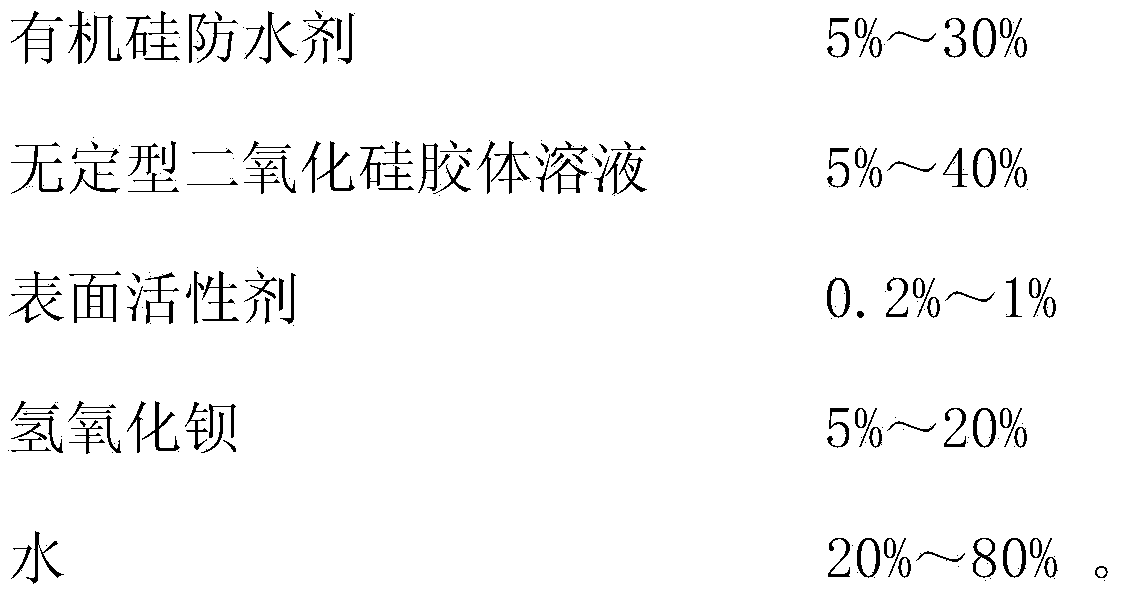

[0046] Water-based penetrating crystalline waterproofing agent, its components and the weight percentage of each component are 49.5% of water, 20% of organic silicon waterproofing agent, 25% of amorphous silica colloidal solution, 0.5% of surfactant, and 5% of barium hydroxide. The preparation method is to weigh and add the above-mentioned components into the reaction kettle in sequence, then heat to 60°C, keep stirring for 60 minutes, then cool down to room temperature, filter to remove impurities, and obtain the osmotic crystal water repellent of the present invention.

Embodiment 2

[0048]Water-based penetrating crystalline waterproofing agent, its components and the weight percentage of each component are 44.5% of water, 10% of organic silicon waterproofing agent, 40% of amorphous silica colloidal solution, 0.5% of surfactant, and 5% of barium hydroxide. The preparation method is to weigh and add the above-mentioned components to the reaction kettle in sequence, then heat to 65°C, keep stirring for 50 minutes, then cool down to room temperature, filter to remove impurities, and obtain the osmotic crystal water repellent of the present invention.

Embodiment 3

[0050] Water-based penetrating crystalline waterproofing agent, its components and the weight percentage of each component are 49.5% of water, 15% of organic silicon waterproofing agent, 30% of amorphous silica colloidal solution, 0.5% of surfactant, and 5% of barium hydroxide. The preparation method is to weigh and add the above-mentioned components to the reaction kettle in sequence, then heat to 65°C, keep stirring for 50 minutes, then cool down to room temperature, filter to remove impurities, and obtain the osmotic crystal water repellent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com