A kind of environmentally friendly flame-retardant low-odor modified polypropylene and its preparation method and application

A polypropylene and low-odor technology, applied in the field of polypropylene materials, can solve the problems of poor mechanical properties, low flame retardant efficiency, and unsatisfactory performance, and achieve low smoke density, low smoke density, and good flame retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

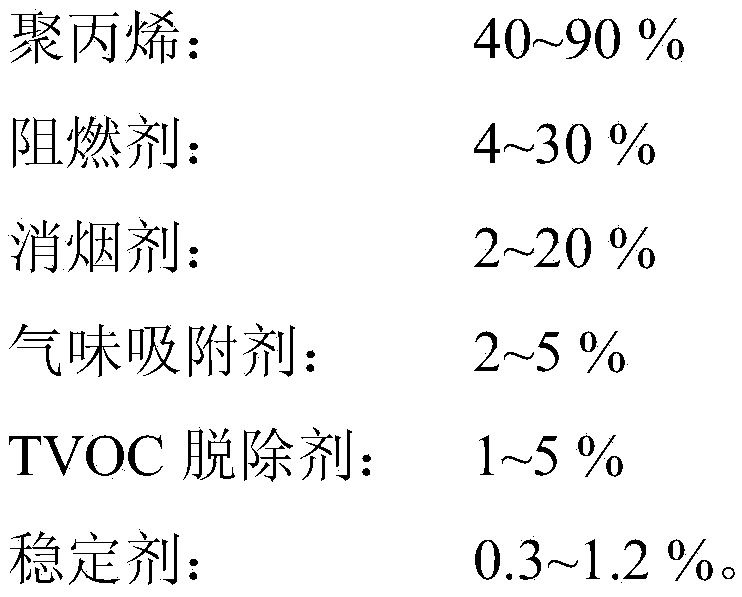

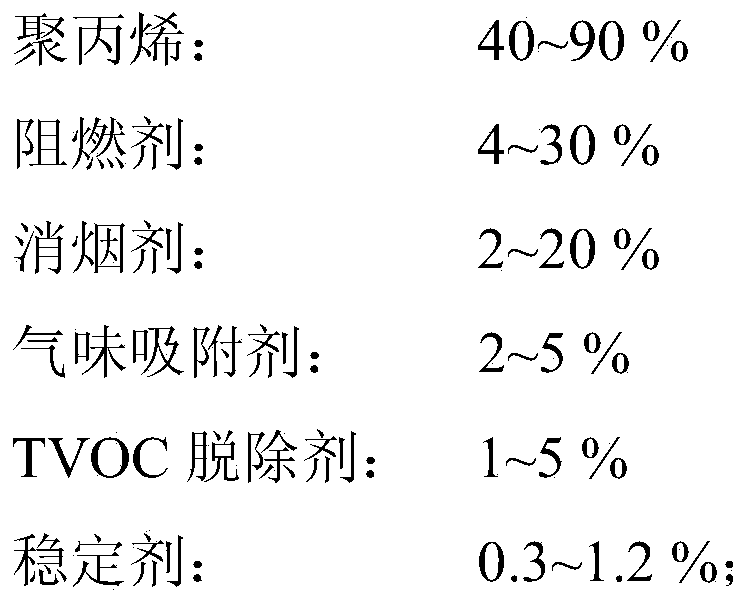

[0033] Example 1: Preparation of environmentally friendly flame-retardant and low-odor modified polypropylene

[0034] Add 69Kg of polypropylene, 20Kg of flame retardant, and 5Kg of smoke suppressant into a low-speed mixer at 100r / min for mixing, then add 3Kg of TVOC remover for mixing, then add 3Kg of odor adsorbent and 0.6Kg of stabilizer for mixing, Added at the main feeding port of the twin-screw extruder, melted and blended, and vacuum-extruded and granulated by the extruder to obtain the special environmentally friendly flame-retardant and low-odor modified polypropylene material for school buses; the twin-screw extruder The length-to-diameter ratio is 36:1, and the processing temperature of the twin-screw extruder is 180°C.

[0035] Among them, the polypropylene used is copolymerized polypropylene, the TVOC removal agent is isopropanol, the halogen-free flame retardant is nitrogen-phosphorus flame retardant (Zhenjiang Star Flame Retardant APP), the smoke suppressant is ...

Embodiment 2

[0036] Example 2: Preparation of environmentally friendly flame-retardant and low-odor modified polypropylene

[0037] Add 40Kg polypropylene, 30Kg flame retardant, and 20Kg smoke suppressant to a low-speed mixer at 100r / min for mixing, then add 5KgTVOC remover for mixing, then add 5Kg odor adsorbent and 1.2Kg stabilizer for mixing, Added at the main feeding port of the twin-screw extruder, melted and blended, and vacuum-extruded and granulated by the extruder to obtain the special environmentally friendly flame-retardant and low-odor modified polypropylene material for school buses; the twin-screw extruder The length-to-diameter ratio is 48:1, and the processing temperature of the twin-screw extruder is 200°C.

[0038] Among them, the polypropylene used is homopolypropylene, the TVOC removal agent is ethanol, the halogen-free flame retardant is nitrogen-phosphorus flame retardant (Zhenjiang Xingxing flame retardant MPP), the smoke suppressant is aluminum hydroxide, and the od...

Embodiment 3

[0039] Example 3: Preparation of environmentally friendly flame-retardant and low-odor modified polypropylene

[0040]Add 89Kg of polypropylene, 5Kg of flame retardant, and 2Kg of smoke suppressant into a low-speed mixer at 100r / min for mixing, then add 1Kg of TVOC remover for mixing, then add 2Kg of odor adsorbent and 0.3Kg of stabilizer for mixing, Added at the main feeding port of the twin-screw extruder, melted and blended, and vacuum-extruded and granulated by the extruder to obtain the special environmentally friendly flame-retardant and low-odor modified polypropylene material for school buses; the twin-screw extruder The length-to-diameter ratio is 52:1, and the processing temperature of the twin-screw extruder is 210°C.

[0041] Among them, the polypropylene used is copolymerized polypropylene, the TVOC removal agent is isopropanol, the halogen-free flame retardant is nitrogen-phosphorus flame retardant (Kaifeng Huashun HS-NPS-D), and the smoke suppressant is aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com