Construction method for embedding pipelines in autoclave aerated concrete block walls

A technology of autoclaved gas filling and construction method, which is applied in the direction of building components, buildings, building structures, etc. It can solve the problems of filling cracks in the wall and plastering hollows on the wall, so as to eliminate indoor water leakage defects and reduce costs , to ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Construction methods include:

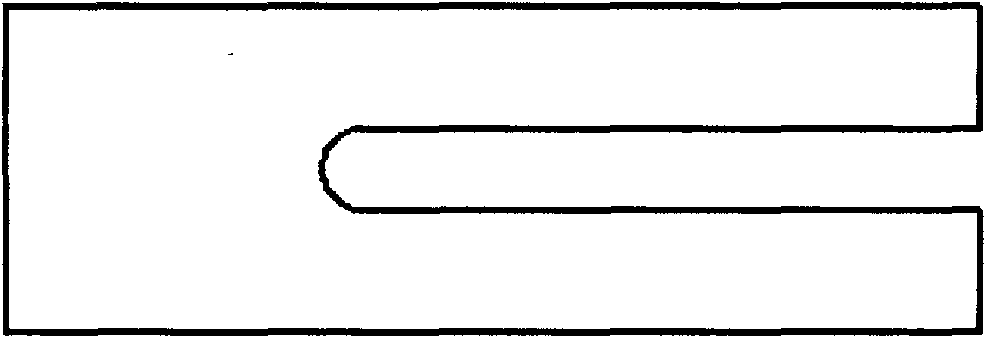

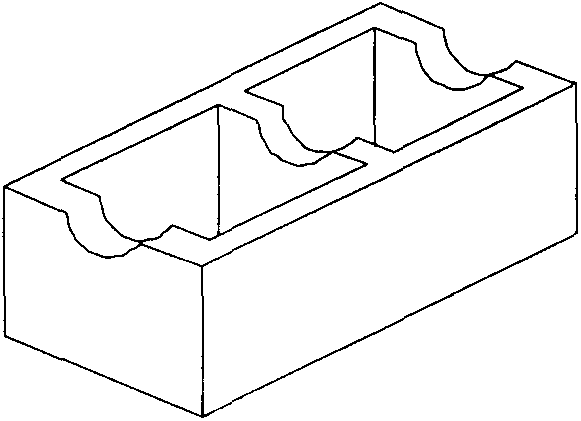

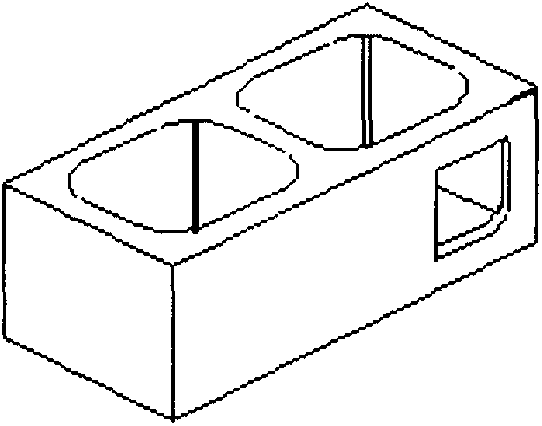

[0014] 1) As attached figure 1 As shown, the infill wall block is cut into a "匚" groove-shaped gap at the pre-buried pipeline; the length of the "匚" groove-shaped gap is 2 / 3 of the block, and the height is 1 / 2 of the block height, and the position centered;

[0015] 2) According to the design intention of the drawing and the function and direction of the pipeline, bury the pipeline in the cast-in-place concrete structure and expose the concrete surface by 300-400mm, and wrap the exposed pipeline interface on the bottom of the beam and the cast-in-place plate with tape to protect;

[0016] 3) Pipeline layout: install and fix the pipeline according to the axis, elevation, pipeline arrangement diagram and layout diagram;

[0017] 4) Block bottoming and masonry: before masonry, a trial arrangement is carried out according to the reserved position of the pipeline according to the block modulus, to ensure that the upper and lower seams are st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com