Boom system of wet spraying machine

A technology of wet spraying machine and jib, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc. It can solve the problems of poor control of shotcrete quality, easy rebound and collapse of concrete, and great impact on workers' health, etc. problem, achieve the effect of reducing labor intensity of workers, improving construction quality and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

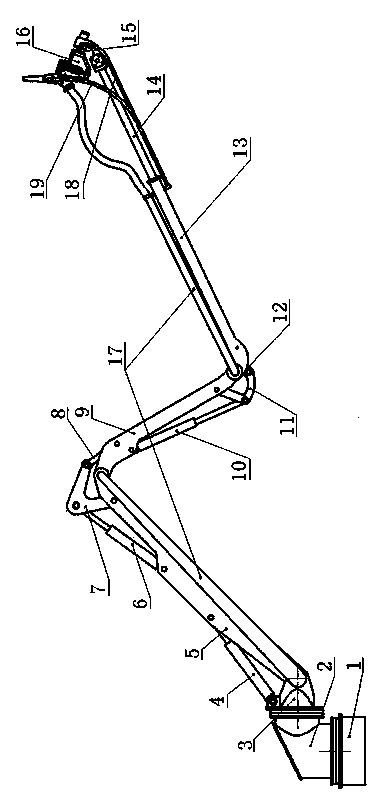

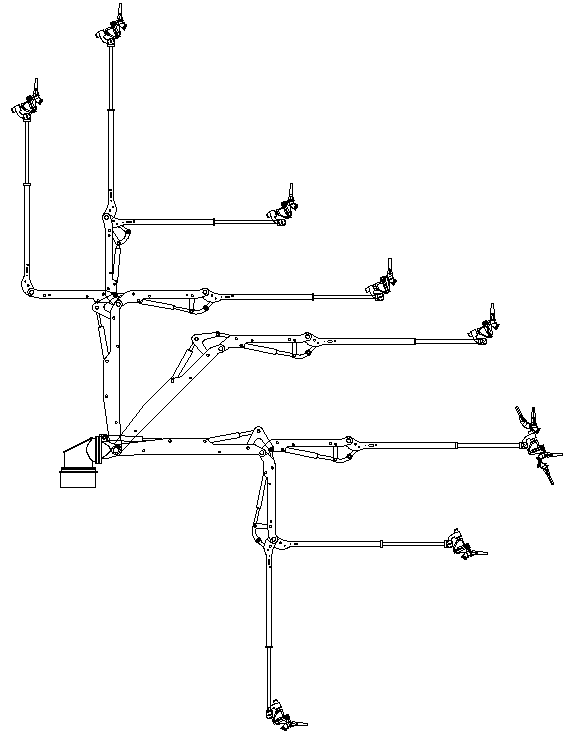

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] Such as figure 1 As shown, a wet spraying machine arm support system includes a base 1, a vertical turntable 2, a horizontal turntable 3, a large arm 5, a middle arm 9, a small arm 13, a telescopic arm 14, a spraying device 15, an oil cylinder, and a connecting rod , concrete delivery pipe 17, high-pressure air delivery pipe 18 and hydraulic oil pipe 19; the base 1 and the vertical turntable 2 are connected through a rotary support, and the horizontal turntable 3 is connected with the vertical turntable 2 through a rotary support; the vertical turntable 2 drives the horizontal The turntable 3 can complete the turning action, and the rotation angle range is -180°~180°; the horizontal turntable 3 is hinged to one end of the boom 5, and the first oil cylinder 4 is arranged between the horizontal turntable 3 and the boom 5 to realize the boom 5 The pitching action rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com