Concrete sprayer

A concrete sprayer and sprinkler assembly technology, which is applied in earthwork drilling, excavation, wellbore lining, etc., can solve problems such as low construction efficiency, dead angle, and harsh construction environment, achieve high construction quality and efficiency, and reduce springback and collapse Fall, improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

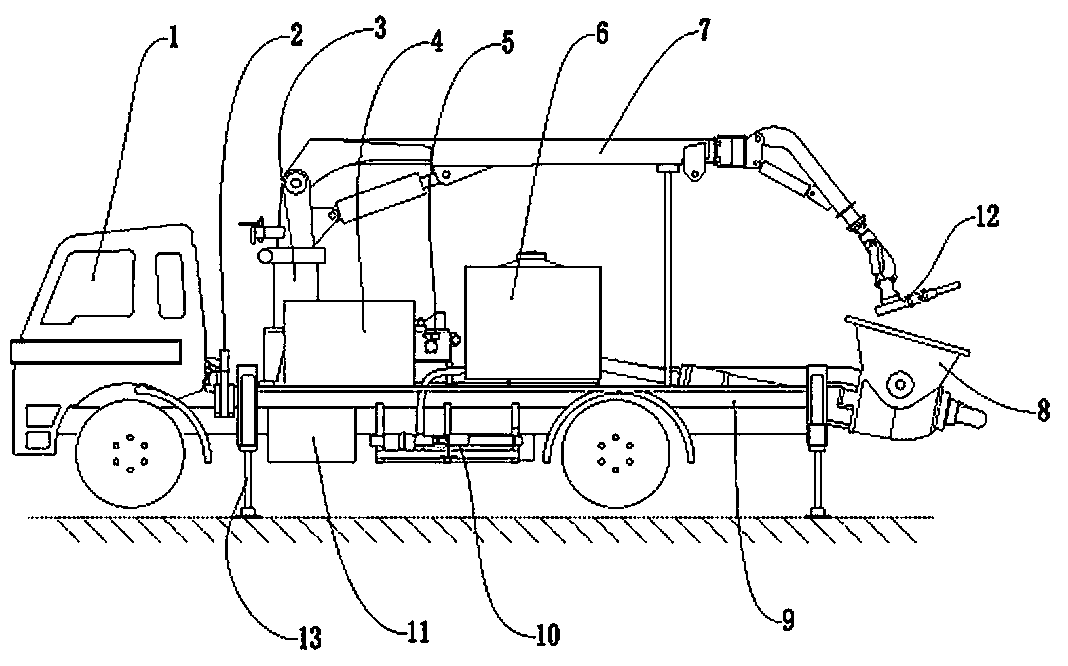

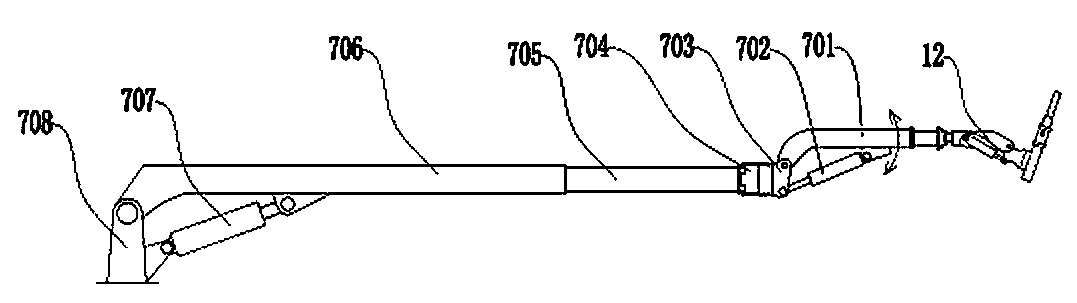

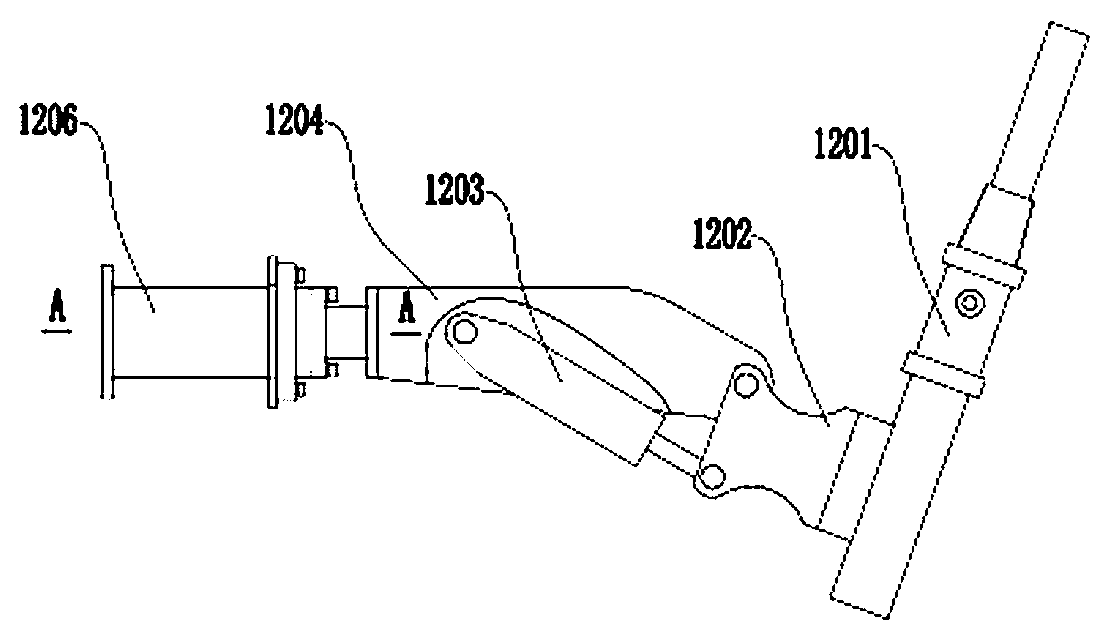

[0027] like figure 1 As shown, the present embodiment includes an automobile chassis 1, an automobile power system 2, a subframe 9 connected to the automobile chassis 1, a fixed turret 3, an electric control system 4, a hydraulic system 5, and an outer frame 9 are installed on the subframe 9. Additive tank 6, pumping system 8, metering system 10, air compressor system 11 and support feet 13, the boom system 7 is installed on the upper end of the fixed turret 3 through a slewing bearing connection, and the boom system 7 is installed with Injection device 12. Described automobile power system 2 can select diesel engine for use; The effect of described support foot 13 is, when carrying out spraying operation, plays support and fixation role, and when moving, support foot 13 shrinks to sub-frame 9 and leaves the ground; The upper end of the fixed turret 3 described above is connected by a slewing bearing to install the boom system 7, which can be realized in the form of a motor +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com