A tbm special mixed injection system

A technology of mixed injection and control system, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of non-customization, high cost, high TBM space requirements, reduce rebound and slump, easily control, improve The effect of equipment competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

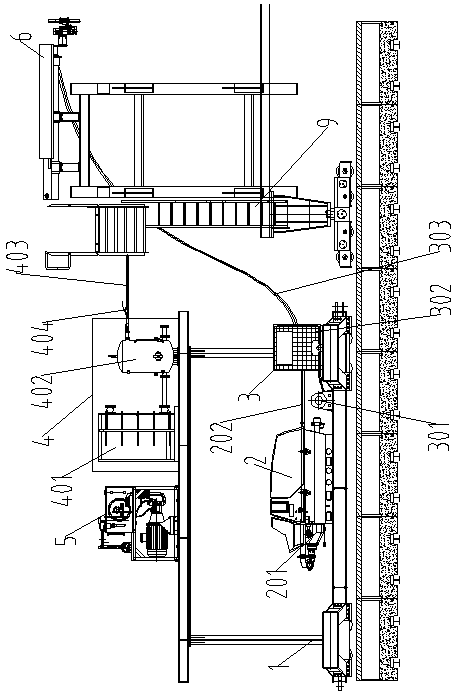

[0018] Embodiment 1: as figure 1 As shown, a special spraying system for TBM is characterized in that it includes a supporting trolley 1, a concrete pumping system 2, an additive system 3, an air compressor system 4 connected to the TBM air supply system, and a TBM hydraulic pump Station connected power source control system 5, wet spray manipulator 6 connected with walking cart 9; concrete pumping system 2, additive system 3, air compressor system 4, power source control system 5 are all installed on the rear supporting platform On the vehicle 1, the power source control system 5 is respectively connected with the concrete pumping system 2 and the wet spraying manipulator 6, and the wet spraying manipulator 6 is connected with the concrete pumping system 2, the additive system 3 and the air compressor system 4 respectively.

Embodiment 2

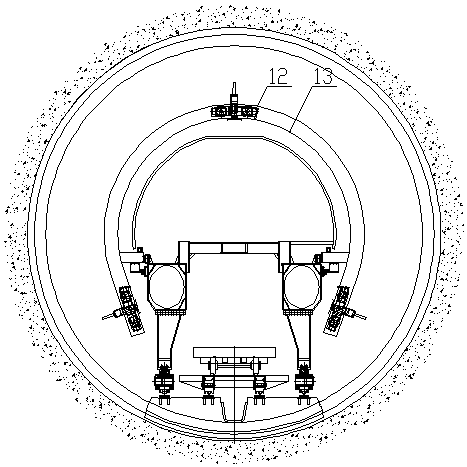

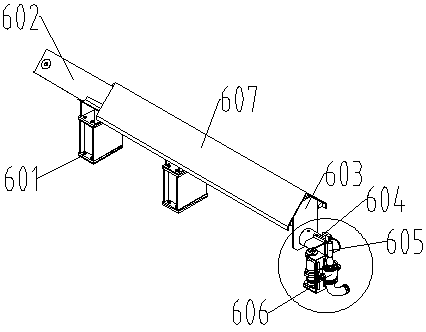

[0019] Embodiment 2: as Figure 1-3 As shown, a special spraying system for TBM includes post-supporting trolley 1, concrete pumping system 2, additive system 3, air compressor system 4 connected with TBM air supply system, and hydraulic pump station connected with TBM The power source control system 5, the wet spray manipulator 6 connected with the walking cart 9; the concrete pumping system 2, the additive system 3, the air compressor system 4, and the power source control system 5 are all installed on the supporting trolley 1, The power source control system 5 is respectively connected with the concrete pumping system 2 and the wet spraying manipulator 6, and the wet spraying manipulator 6 is connected with the concrete pumping system 2, the additive system 3 and the air compressor system 4 respectively. Described wet spray manipulator 6 comprises base 601, big arm 602, forearm 603, injection device 604, nozzle 605 and flow mixer 606, and big arm 602 is fixed on the support...

Embodiment 3

[0020] Embodiment 3: as Figure 1-4 As shown, a special spraying system for TBM includes post-supporting trolley 1, concrete pumping system 2, additive system 3, air compressor system 4 connected with TBM air supply system, and hydraulic pump station connected with TBM The power source control system 5 and the wet spraying manipulator 6 connected with the walking cart 9, the concrete pumping system 2 is placed sideways in the middle of the supporting trolley 1, and the concrete pumping system 2 includes a concrete pump 201 and a concrete delivery soft The pipe 202, the outlet end of the concrete pump 201 is connected with the input end of the conveying hose 202, which provides the driving force for conveying the concrete. Under the action of the concrete pump, the concrete enters the concrete conveying hose 202. The additive system 3 is placed sideways on the rear supporting trolley 1 and is located in front of the concrete pumping system 2. The additive system 3 includes an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com