Seal decreasing centrifugal compressor

A centrifugal compressor and hollow shaft technology, applied in the field of air-conditioning compressors, can solve the problems of high noise, low air tightness coefficient, low energy efficiency ratio, etc., and achieve the effects of improving the cooling and heat exchange rate, small volume and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

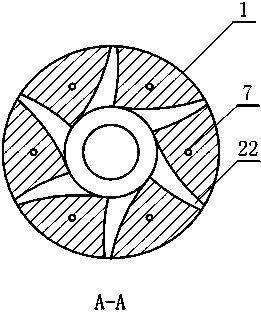

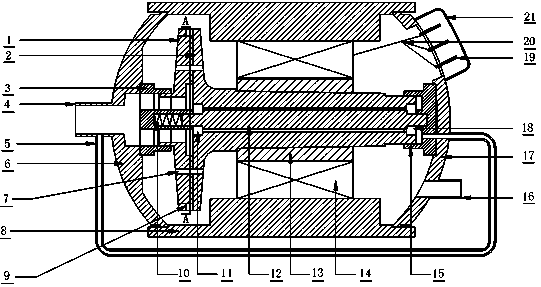

[0011] exist figure 1 Among them, the closed centrifugal compressor includes: centrifugal wheel 1, wheel tray 2, a cylinder 3, intake pipe 4, heat dissipation pipe 5, a end cover 6, bolt holes 7, casing 8, flow channel outlet 9 , spring 10, a bearing 11, main shaft 12, rotor 13, stator 14, b cylinder 15, exhaust pipe 16, b end cover 17, b bearing 18, terminal 19, wiring 20, junction box 21, flow channel 22, The closed degressive centrifugal compressor is provided with an annular disc-shaped centrifugal disc 1, and the centrifugal disc 1 is uniformly provided with bolt holes 7 for the convenience of connecting bolts; Decreasing flow channel 22, the cross-sectional area of each point in the longitudinal direction of the flow channel 22 is calculated according to the thermodynamic characteristics of the refrigerant used in the compressor and determined through multiple tests. Carry out gradual compression, which solves the surge phenomenon of the transmission centrifugal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com