Adaptive hydraulic circuit and control method for rotary propulsion of hydraulic drilling rig

A technology of hydraulic drilling rig and rotary propulsion, which is used in drill pipe, drill pipe, earth-moving drilling and mining, etc., can solve the problem that the propulsion speed is difficult to realize the rotation, propulsion, damage of the drill thread, and the propulsion speed of the rock drill is not adjusted, etc. problems, to achieve the effect of improving the overall operation efficiency of the whole machine, smooth realization, and prolonging the life of the drilling tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

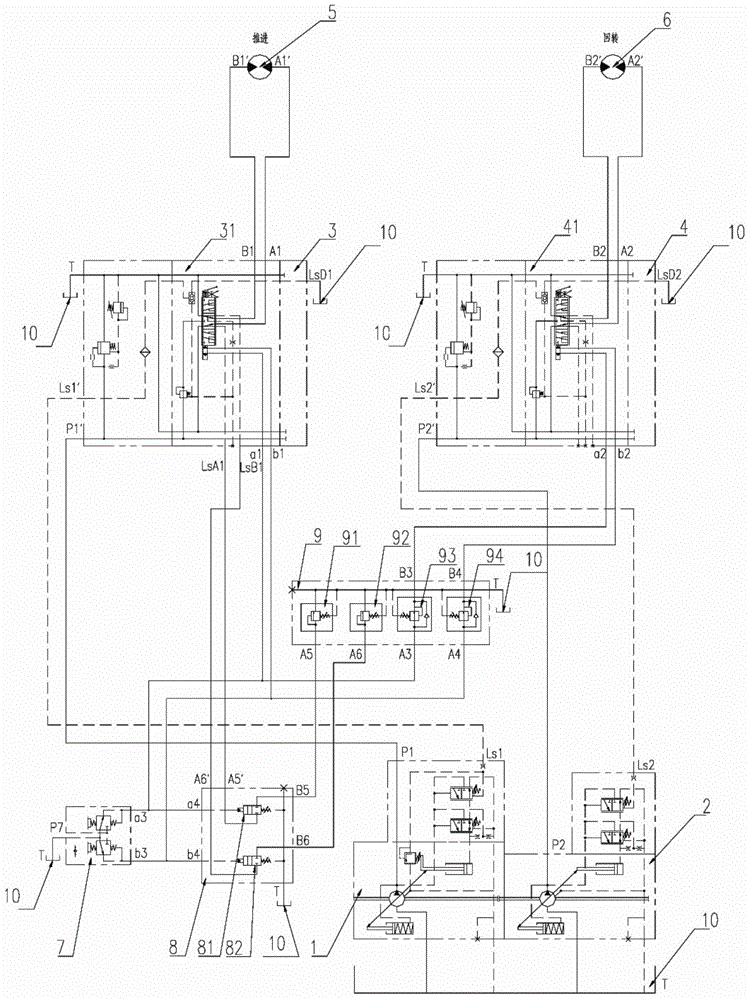

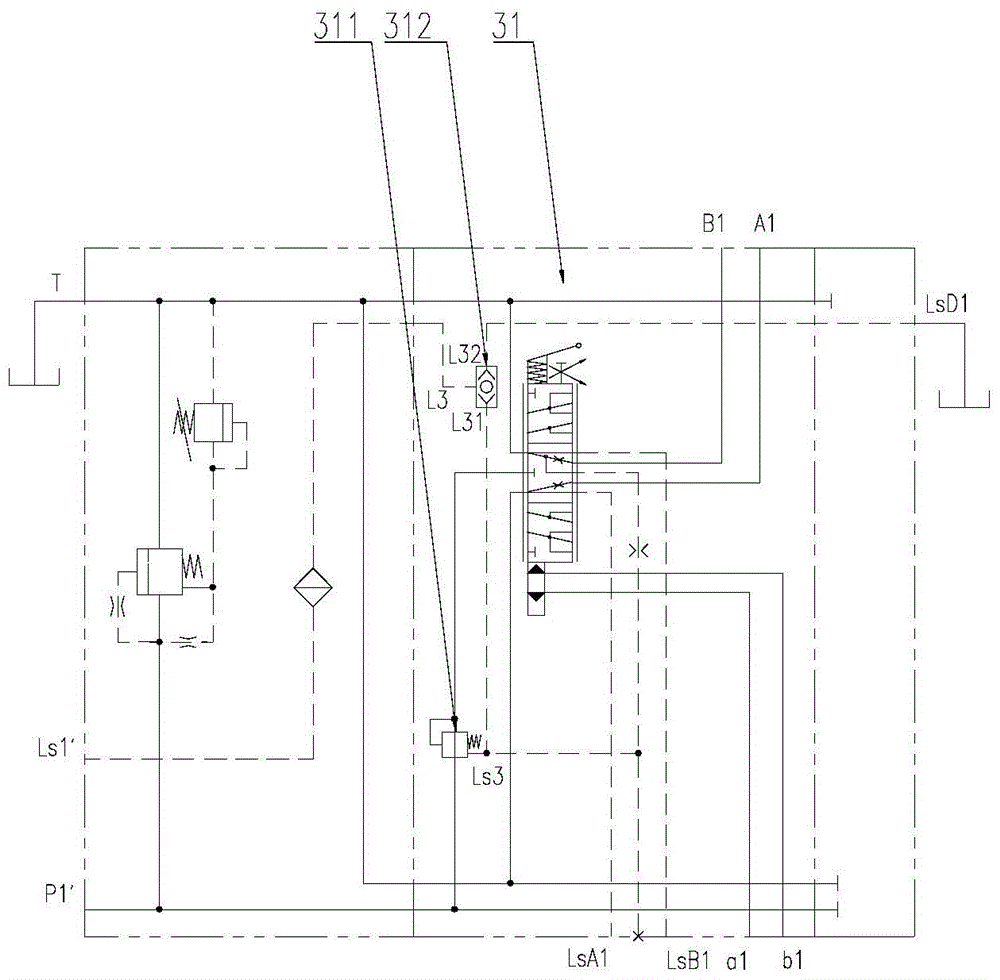

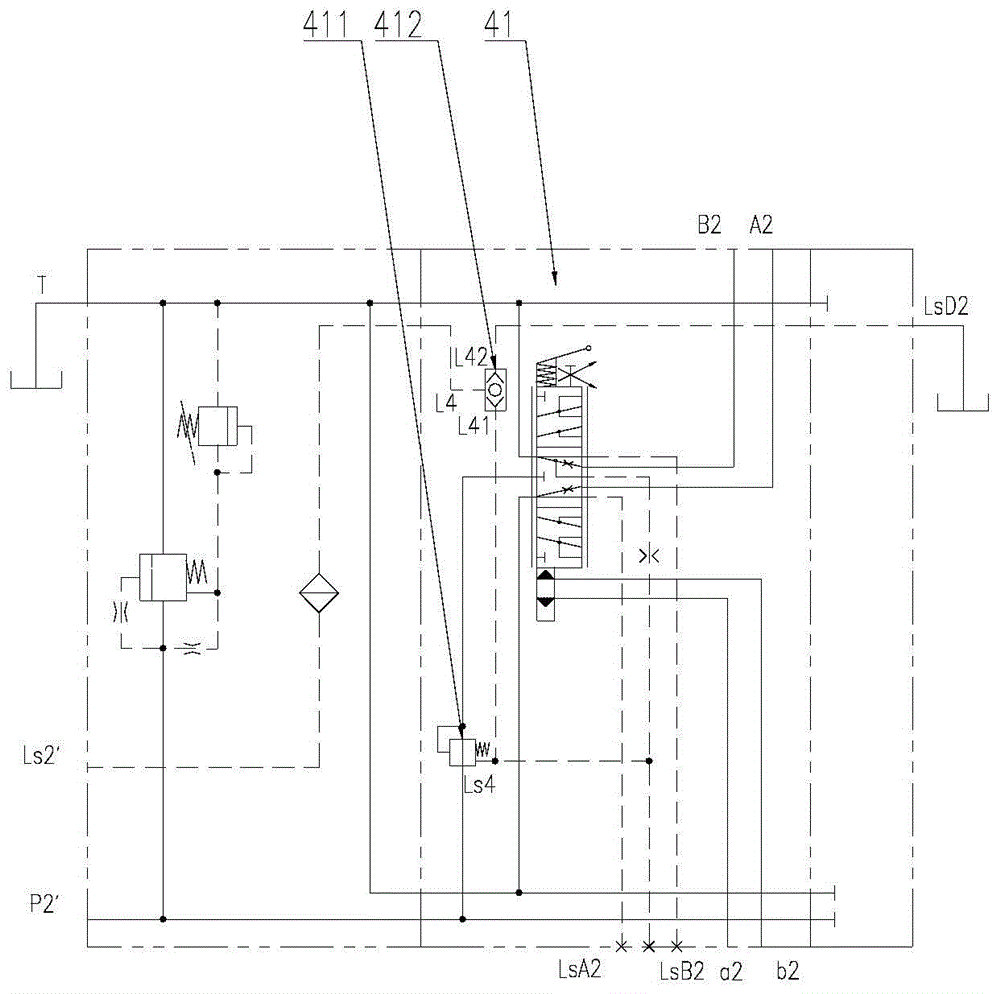

[0026] The hydraulic drilling rig connects and unloads the brazing rotary propulsion self-adaptive hydraulic circuit, including the rock drill propulsion main oil circuit composed of the first load-sensitive variable pump 1, the first load-sensitive proportional multi-way valve 3, the propulsion motor or oil cylinder 5, and the hydraulic oil tank 10; The first load-sensing proportional multi-way valve 3 includes a first link, a propulsion link 31, a tail link, etc., wherein the propulsion link 31 has a differential pressure compensator and a load feedback shuttle valve, and the oil port A1 and the oil port B1 of the propulsion link 31 are A load-sensitive external control port LsA1 and a load-sensitive external control port LsB1 are respectively provided. The flow rate of the spool of the propulsion unit 31 is to satisfy the propulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com