Non-contact conoscopic holography measurement system

A measurement system and non-contact technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of phase shift error, light source fluctuation sensitivity, etc., and achieve the effect of improving measurement accuracy, simplifying optical system, and designing reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

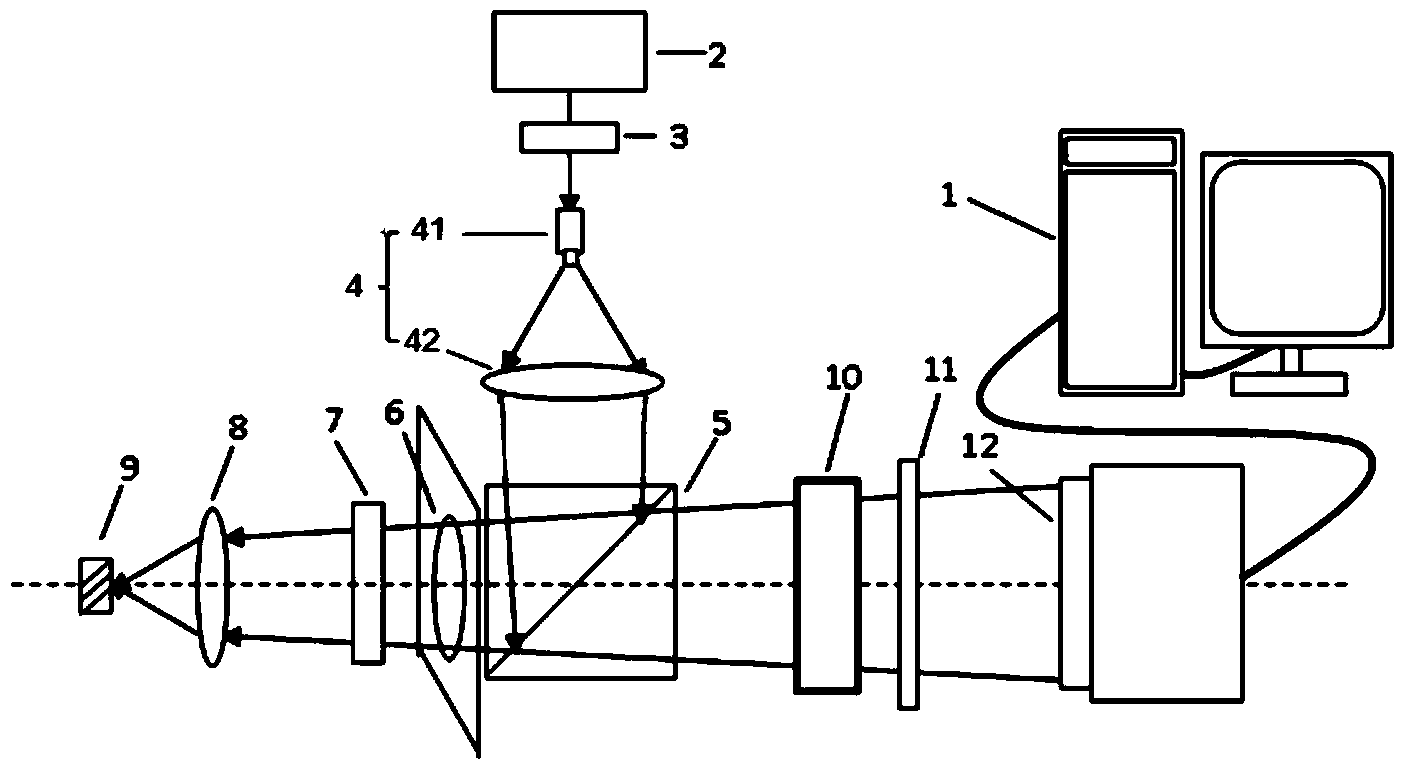

[0014] The high-precision non-contact conoscopic holographic measurement system based on the phase-height method of the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings.

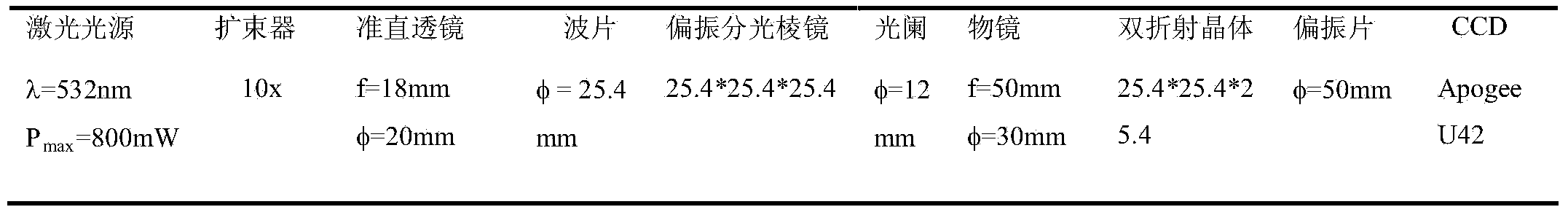

[0015] Such as figure 1 As shown, a high-precision non-contact conoscopic holographic measurement system based on the phase-height method includes a laser system that emits a laser beam, and a laser beam that converges the laser beam that passes through the beam expansion and collimation system 4 to a point of the measured object 9 A light reflection system, a light receiving system for collecting returning light, and a polarization beam splitter prism 5 . Described light reflection system comprises diaphragm 6, λ / 4 glass plate 7 and objective lens 8 arranged along the laser beam advancing line; The light receiving system has birefringent crystal 10, polarizer 11 and Optical camera device 12.

[0016] The light receiving system and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com