Whole optical fiber colorimetric temperature measuring method based on optical fiber bragg grating

A technology of optical fiber Bragg and colorimetric temperature measurement, which is applied in the field of non-contact colorimetric temperature measurement technology and its filtering, can solve the problems of unfavorable application of colorimetric temperature measurement system, complicated assembly and debugging, less optical path improvement, etc. It achieves the effect of facilitating detection, improving precision, and simple optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

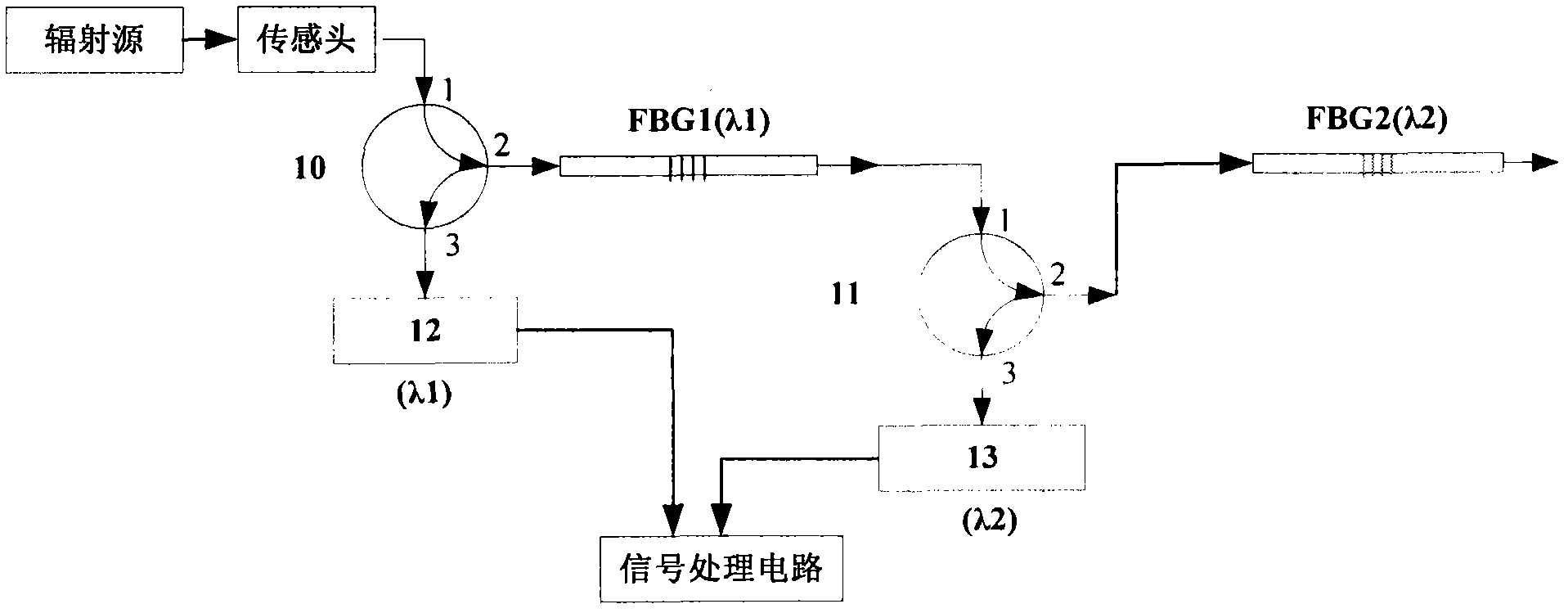

Method used

Image

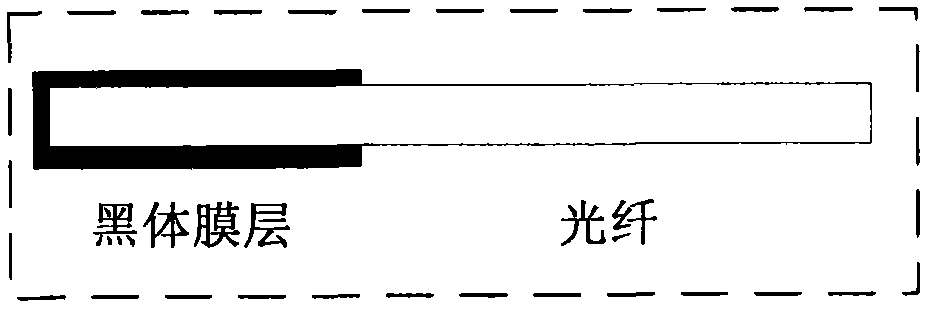

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments.

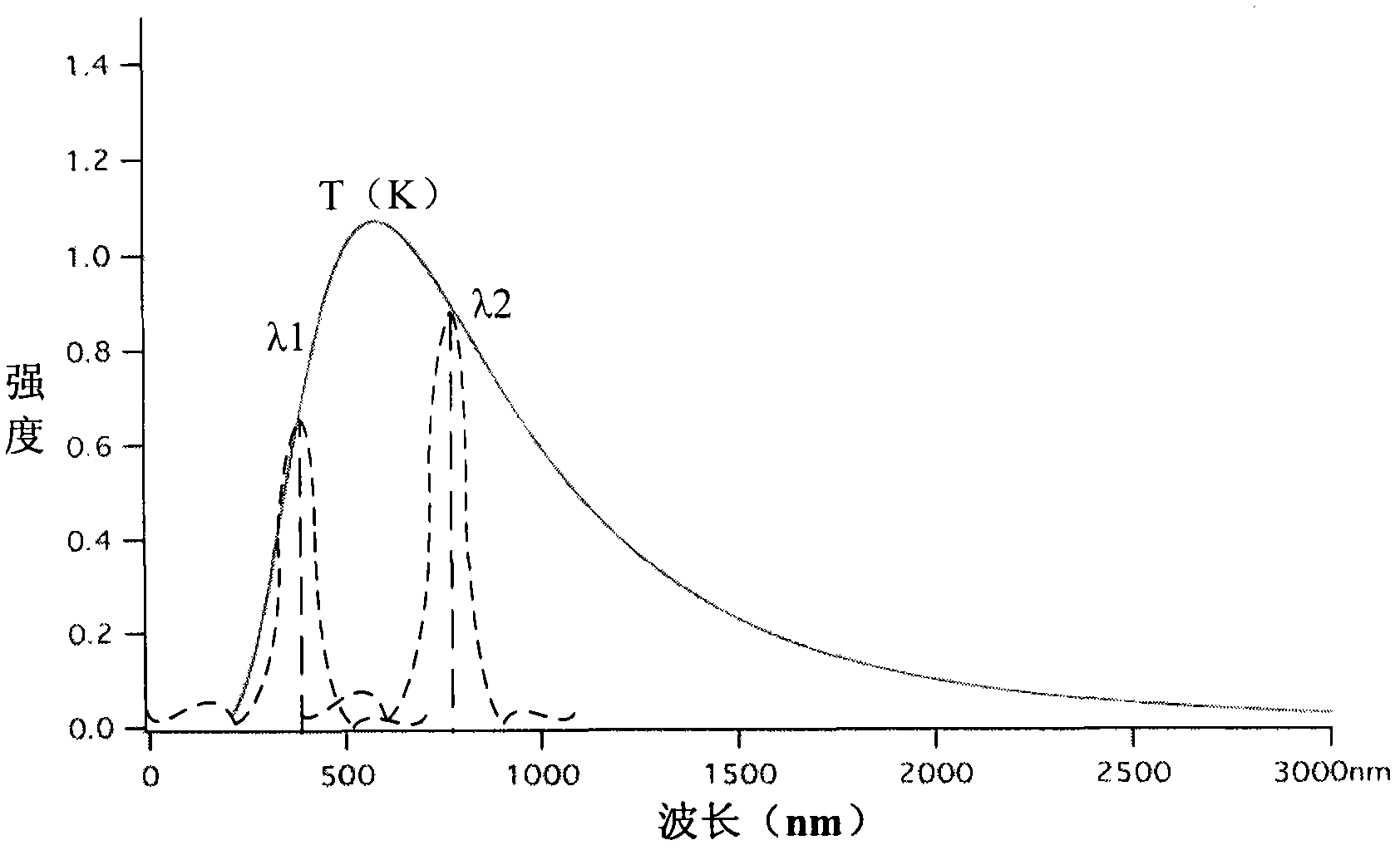

[0027] The principle of colorimetric temperature measurement used in this method is described as follows:

[0028] The radiation and distribution of non-black body matter with thermodynamic temperature T are described by Planck's radiation law:

[0029] M ( λ , T ) = ϵ ( λ , T ) · c 1 λ 5 ( e c 2 / λT - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com