Microscopic CT motion error correction method for rotating shaft

A technology of motion error and correction method, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of reducing three-dimensional spatial resolution and error of CT reconstruction results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The purpose of the present invention is to provide a method for correcting the movement error of the micro-CT rotating shaft so as to improve the three-dimensional spatial resolution of the micro-CT reconstruction results. The measurement method is simple, practical and reliable.

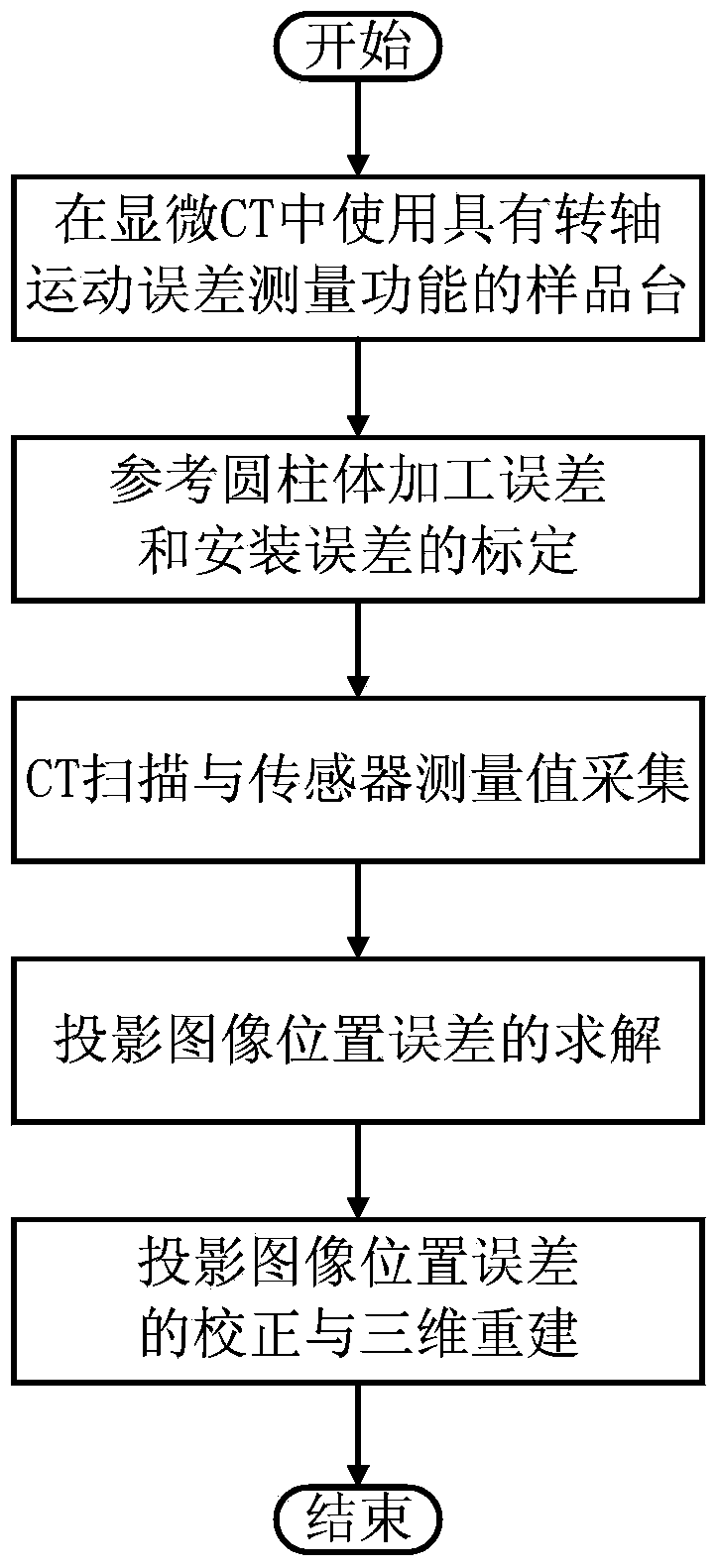

[0033] The present invention is achieved through the following technical solutions, a method for correcting the movement error of a micro-CT rotating shaft, which is characterized in that it includes the following steps:

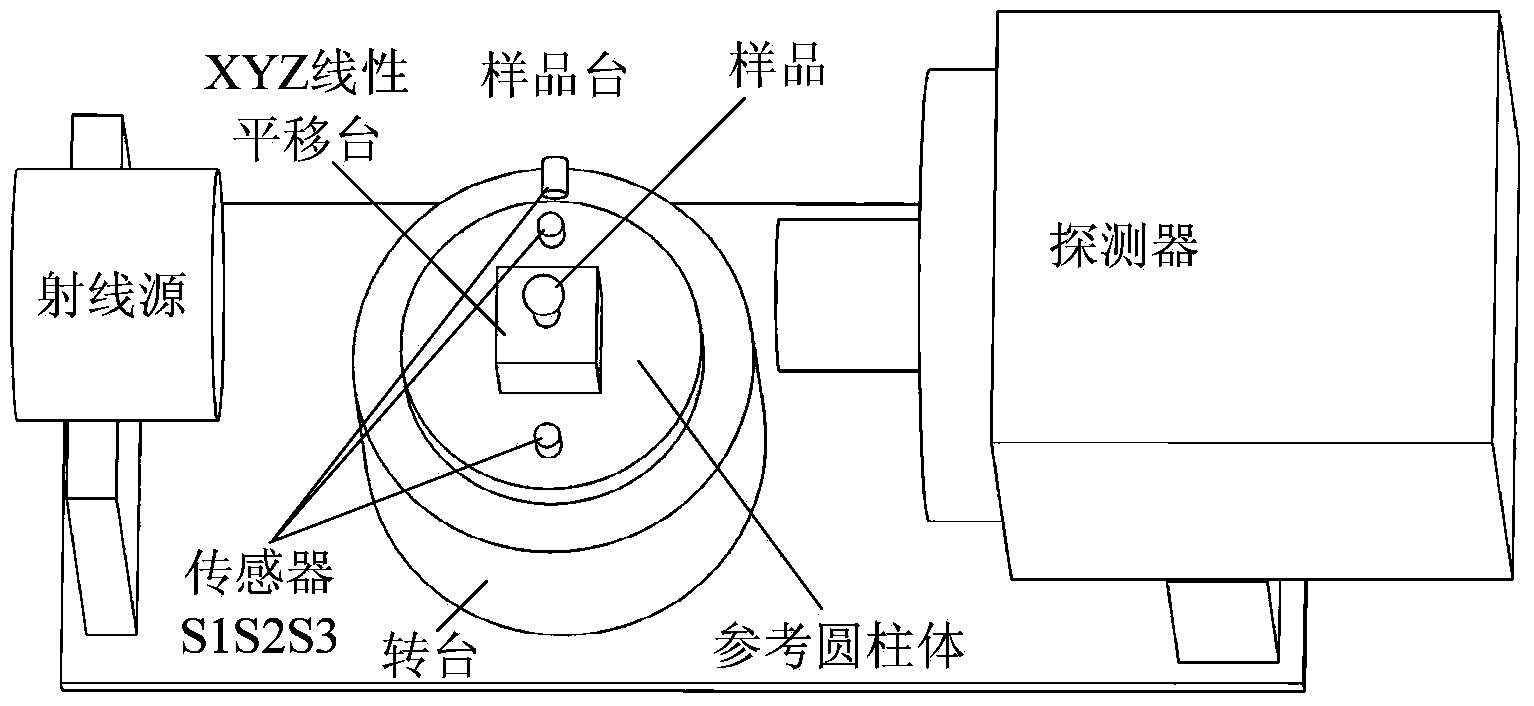

[0034] (1) Install a capacitive sensor and a reference cylinder on the rotating sample stage in micro-CT to monitor the error movement of the rotating shaft;

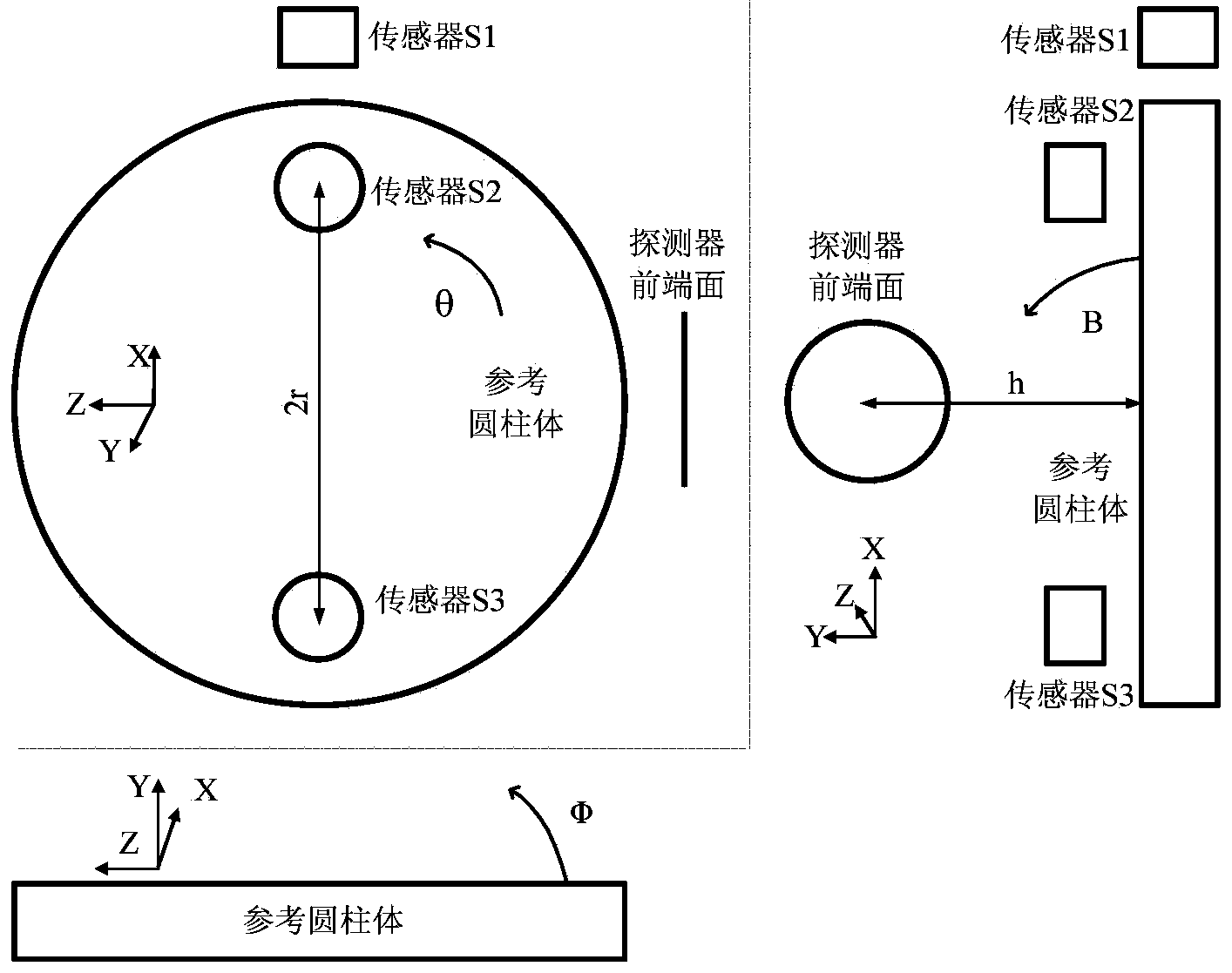

[0035] (2) Calibrate the machining error and installation error of the reference cylinder in the sample stage with the function of measuring the rotation axis error motion;

[0036] (3) During the CT scanning process, the measurement values of the three sensors S1S2S3 are collected while collecting each projection im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com