Unattended operation automatic weighing system and method

A weighing and automatic technology, applied in the direction of measuring devices, instruments, weighing, etc., can solve problems that affect production data and sales data, prone to errors, heavy workload, etc., to reduce driver cheating, improve efficiency, and scientific methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

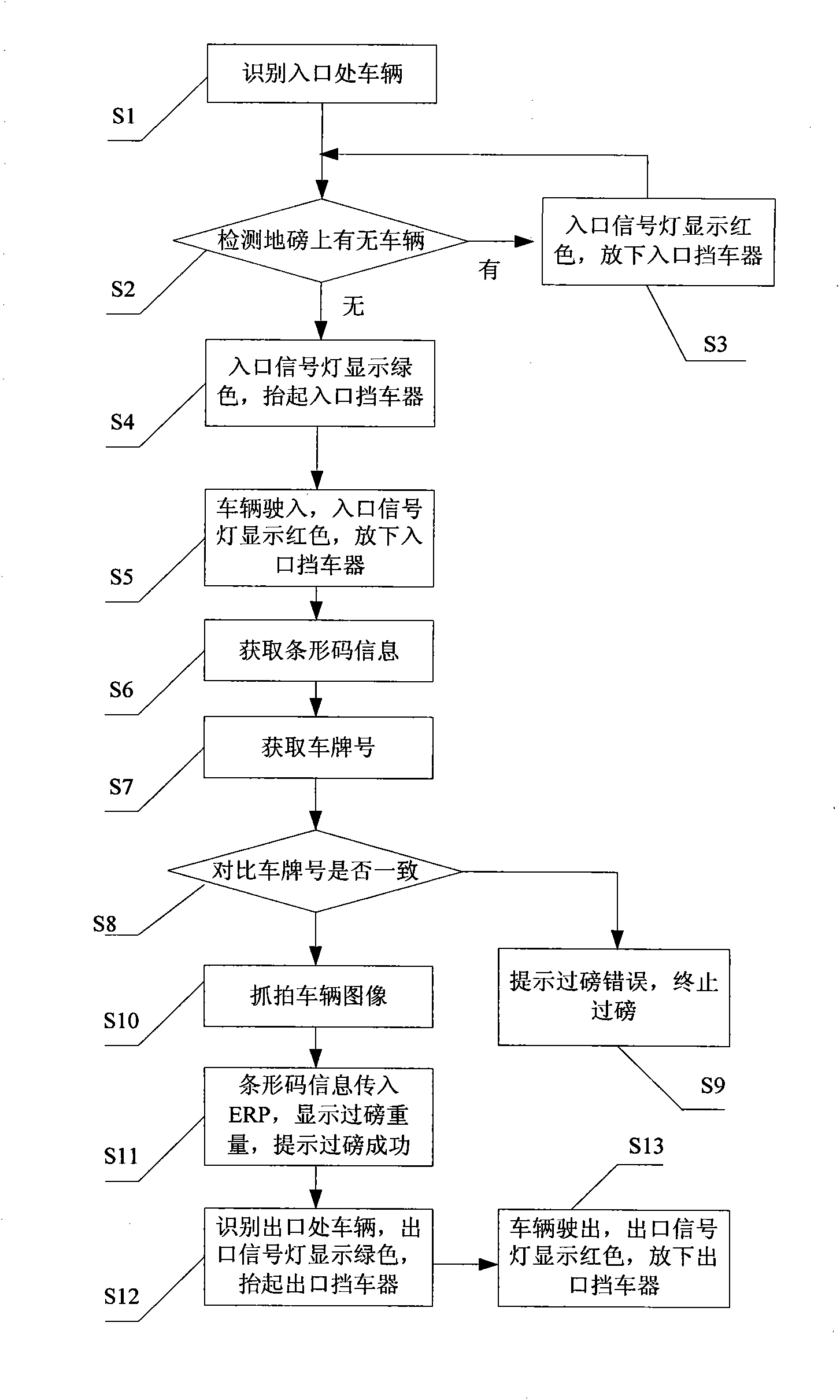

[0041] The present invention will be further described below in conjunction with accompanying drawing.

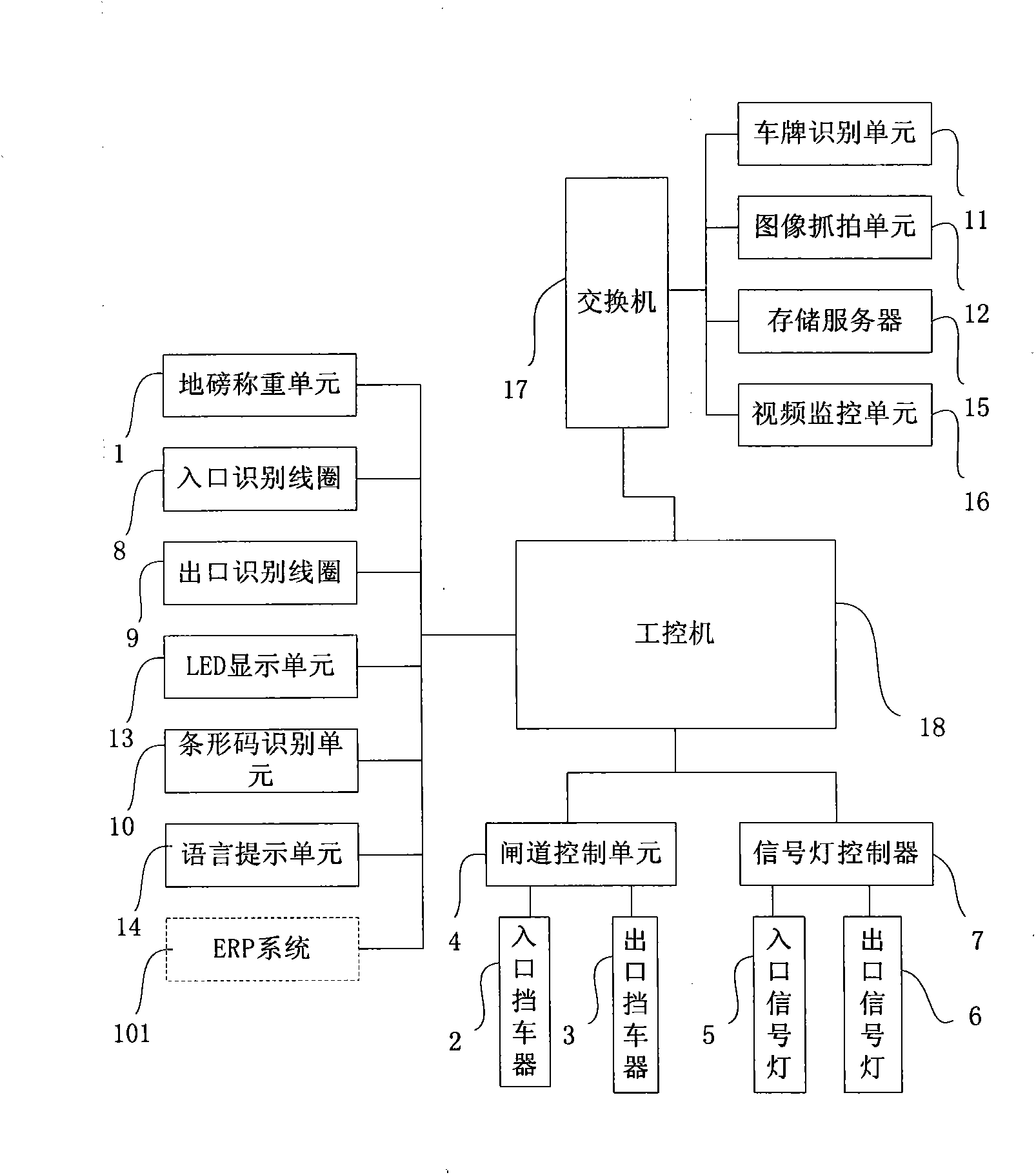

[0042] see figure 1 , an unattended automatic weighing system of the present invention, externally connected to an ERP system 101, including a weighbridge weighing unit 1, an entrance stopper 2, an exit stopper 3, a gate control unit 4, an entrance signal light 5, an exit signal light 6, and a signal light Controller 7, entrance recognition coil 8, exit recognition coil 9, barcode recognition unit 10, license plate recognition unit 11, image capture unit 12, LED display unit 13, language prompt unit 14, storage server 15, video surveillance unit 16, switch 17 and industrial computer 18, wherein:

[0043] The industrial computer 18 is respectively connected with the weighbridge weighing unit 1, the gateway control unit 4, the signal light controller 7, the entrance identification coil 8, the exit identification coil 9, the barcode identification unit 10, the LED display uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com