Sample preparation mold for non-standard brick strength test of masonry wall and its use method

A strength test and sample preparation technology, which is applied in the preparation of test samples, etc., can solve the problems of long curing period, low test efficiency, and poor test reproducibility, so as to improve accuracy and efficiency, improve detection efficiency, and eliminate The effect of severe deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe an embodiment below in conjunction with accompanying drawing, the present invention is described further.

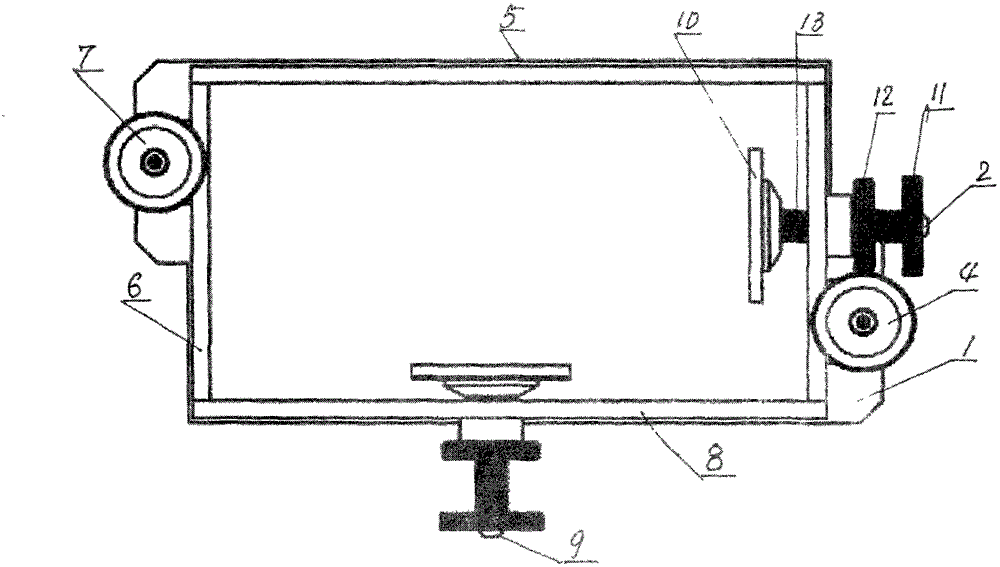

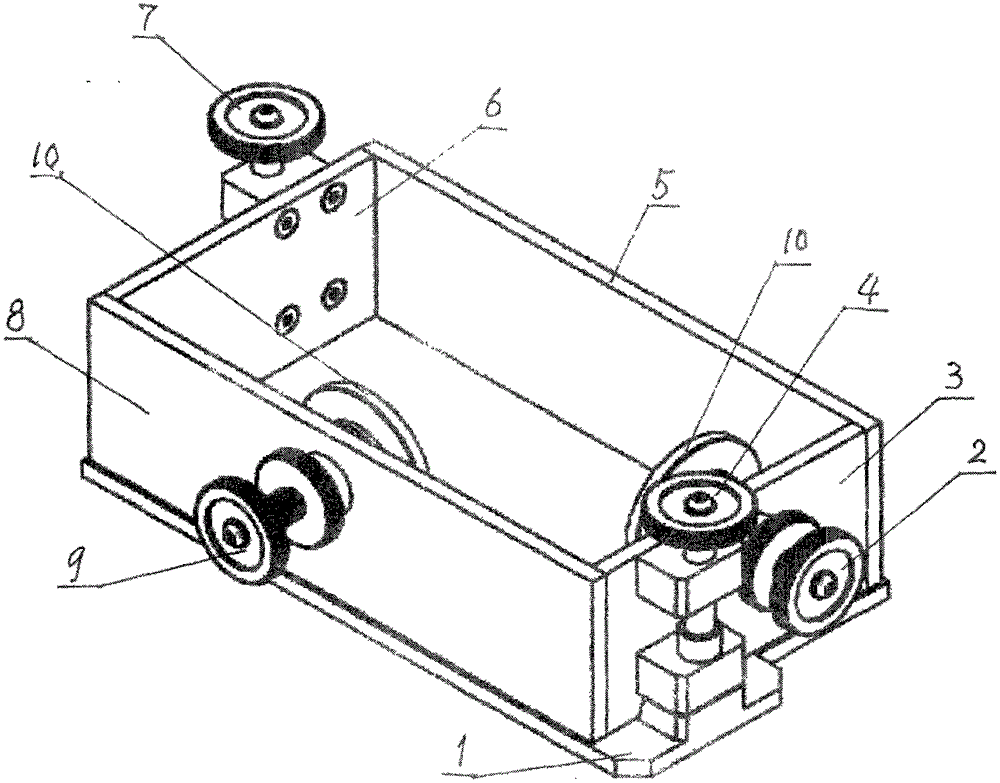

[0034] figure 1 , figure 2 They are the top view schematic diagram and the three-dimensional schematic diagram of the whole of this embodiment respectively.

[0035] This embodiment consists of a bottom plate 1 and a sample preparation mold.

[0036] The sample preparation mold is mainly composed of a right wall 5, a left wall 8, a front wall 3, a rear wall 6, a front clamping device 2, a left clamping device 9, a sealing device and two mold fixing devices.

[0037] Front wall 3, rear wall 6, right wall 5, left wall 8 form a square enclosure. The front wall 3 and the left wall 8 are respectively provided with a front neck tightening device 2 and a left top tightening device 9; the front wall 3 and the rear wall 6 are respectively fixed with a mold fixing device 7.

[0038] Described jacking device mainly is made up of bolt 13, jacking push plate 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com