Rotor magnet-gathering type horizontal magnetic-flow permanent-magnet disc wind driven generator

A wind turbine, transverse magnetic flux technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit static parts and other directions, can solve the complex manufacturing process, high manufacturing process and cost, space utilization, etc. problems such as low rate, to achieve the effect of facilitating design and manufacturing, avoiding invalid situations, and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

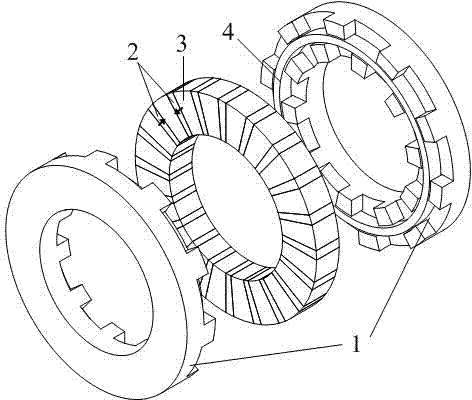

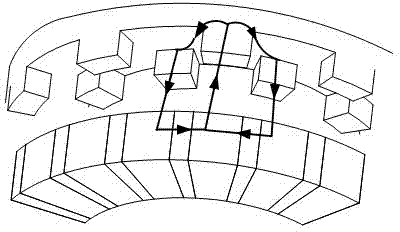

[0021] combine Figure 1~Figure 3 , for a single-phase inner rotor generator, the solid model of the rotor magnetism-concentrating transverse flux permanent disk wind turbine is mainly composed of the following parts: two sets of stator cores 1, N permanent magnets 2, N The rotor core 3 and two sets of armature windings 4 are composed, wherein N≥2. The two sets of stator cores 1 have the same size and are placed opposite to each other in mirror images. They are made of soft magnetic composite materials. The stator core 1 forms stator inner teeth and stator outer teeth in the radial direction, and the inner and outer teeth of the stator are arranged alternately along the circumferential direction. The length of a permanent magnet 2 in the circumferential direction; the armature winding 4 adopts a concentrated annular winding, and is placed in the stator slot formed by the inner and outer teeth of the stator core 1, and two sets of annular armature windings 4 are connected in se...

Embodiment 2

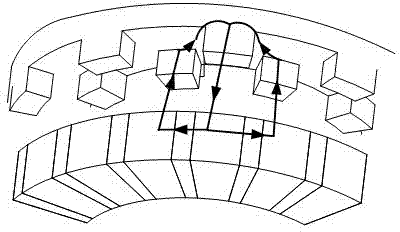

[0023] For a single-phase external rotor generator, the solid model of the rotor-concentrated transverse flux permanent disk wind turbine is mainly composed of the following parts: two sets of stator cores 1, two sets of armature windings 4 and two sets of The rotor as a whole, wherein each set of rotors as a whole includes N permanent magnets 2 and N rotor cores 3, where N≥2. The two sets of stator cores 1 have the same size, are placed back to back inside the motor, and are made of soft magnetic composite materials. The stator core 1 forms stator inner teeth and stator outer teeth in the radial direction, and the stator inner and outer teeth are staggered along the circumferential direction. , separated by the length of a permanent magnet 2 in the circumferential direction; the armature winding 4 adopts a centralized annular winding, and is placed in the stator slot formed by the inner and outer teeth of the stator core 1, and the two sets of annular armature windings 4 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com