High-heat radiation copper-based circuit board

A circuit board, high heat dissipation technology, applied in the direction of printed circuit components, etc., can solve the problem of insufficient heat conduction speed, and achieve the effect of fast heat dissipation speed and strong heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

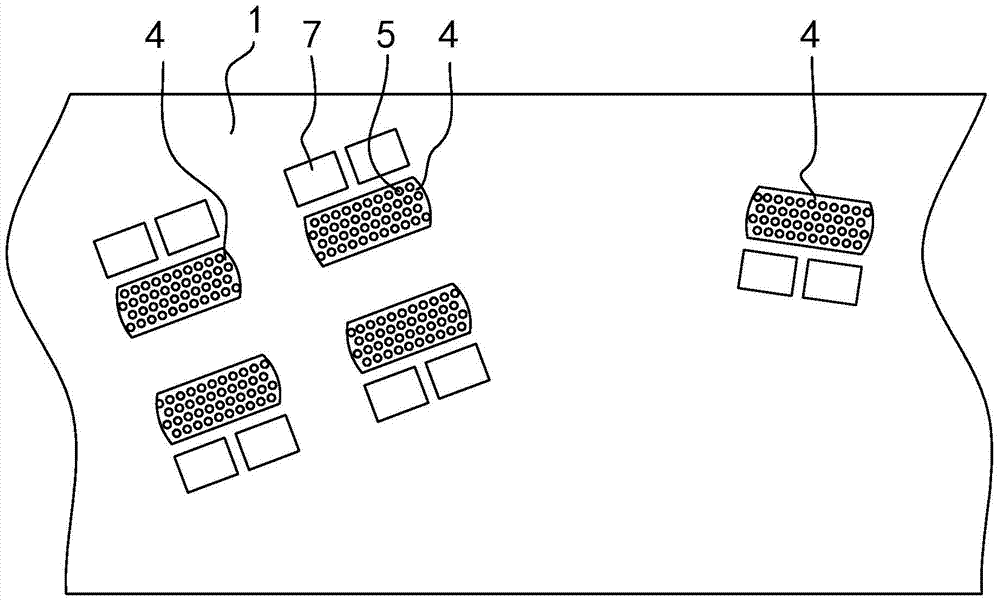

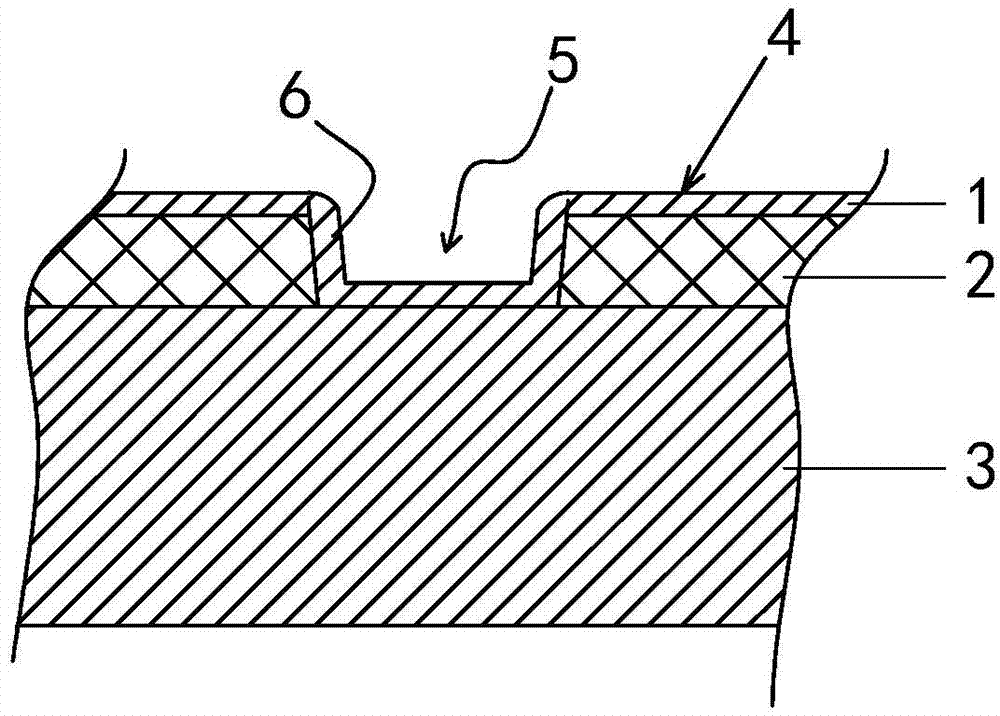

[0014] Example: see figure 1 , figure 2 Shown:

[0015] A copper-based circuit board with high heat dissipation, including a board body, which is composed of three layers of circuit layer 1, insulating and heat-conducting layer 2 and base copper layer 3, see figure 2 .

[0016] see figure 1 , the circuit layer 1 side surface of the board is provided with a reinforced heat dissipation area 4 that does not carry current, and a plurality of blind holes 5 along the thickness direction of the board are arranged in the enhanced heat dissipation area 4 . These blind holes 5 penetrate the circuit layer 1 and the insulating and heat-conducting layer 2, so that the bottom of the blind hole 5 is connected to the base copper layer 3; and, the wall and bottom of each blind hole 5 are covered with a copper plating layer 6, And the wiring layer 1 is connected to the base copper layer 2 through the copper plating layer 6, see figure 2 .

[0017] The blind holes 5 are preferably tiny ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com