Method for making moss wall

A production method and technology of moss walls, applied in botanical equipment and methods, walls, container cultivation, etc., can solve the problems of high maintenance difficulty and single types of green plants, so as to reduce the maintenance difficulty, expand the types, and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

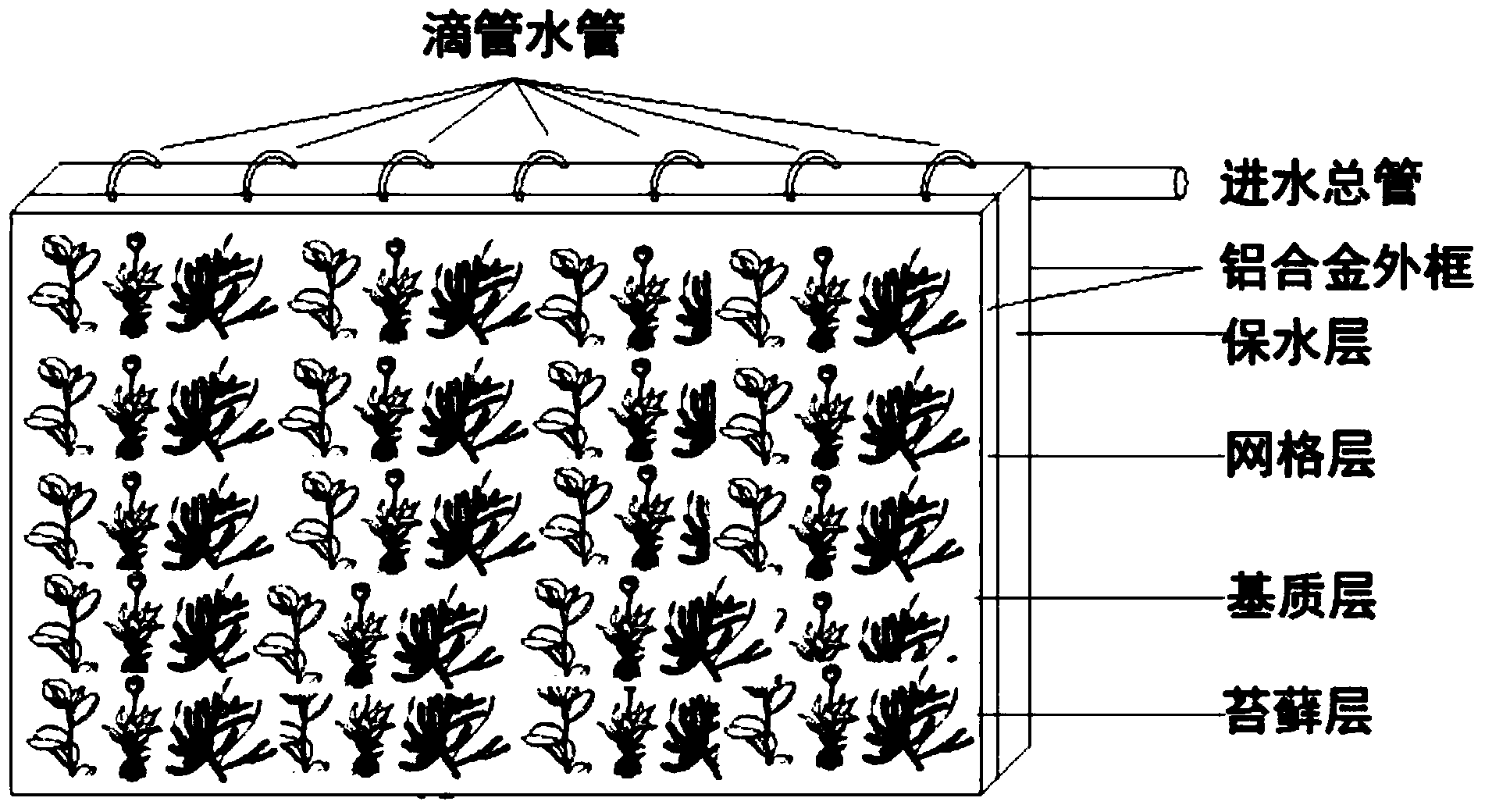

[0015] as attached figure 1 Shown, a kind of making method of moss wall, it comprises the following steps:

[0016] (1) make the framework of moss wall module, described framework is the box of top opening;

[0017] (2) The moss cultivation substrate is constructed, and the water-retaining flower mud layer, the isolation net layer, and the moss growth substrate layer are sequentially filled in the frame;

[0018] (3) Carry out rapid propagation with moss fragments on the substrate layer to form green moss clusters;

[0019] (4) Install the cultivated moss wall module as a whole on the outer wall of the building.

[0020] Further, the frame of the moss wall module in step 1 is provided with a chassis, and the frame is made of aluminum alloy with a length of 100 cm, a length of 60 cm, a width of 5 cm, and a height of 5 cm. The frame is rectangular, and one side of the entire frame is provided with 6 drip channels.

[0021] Further, in the step 2, the water-retaining flower mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com