A horizontal biomass pellet machine

A biomass granule, horizontal technology, applied in the direction of biofuel, raw material extrusion granulation, waste fuel, etc., can solve the problems of not timely maintenance, shortened service life, uneven scraping, etc., to save resources and prolong use. Longevity and uniform scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

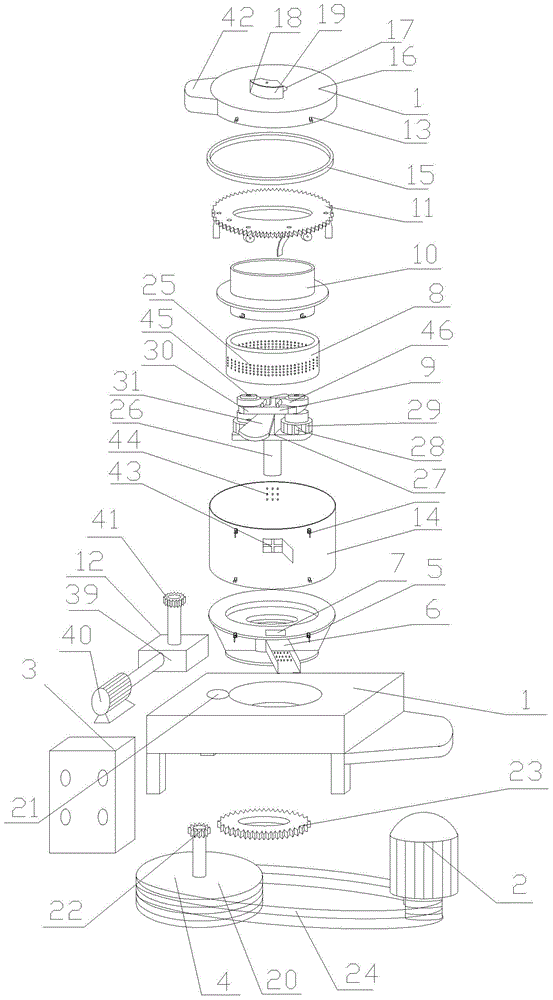

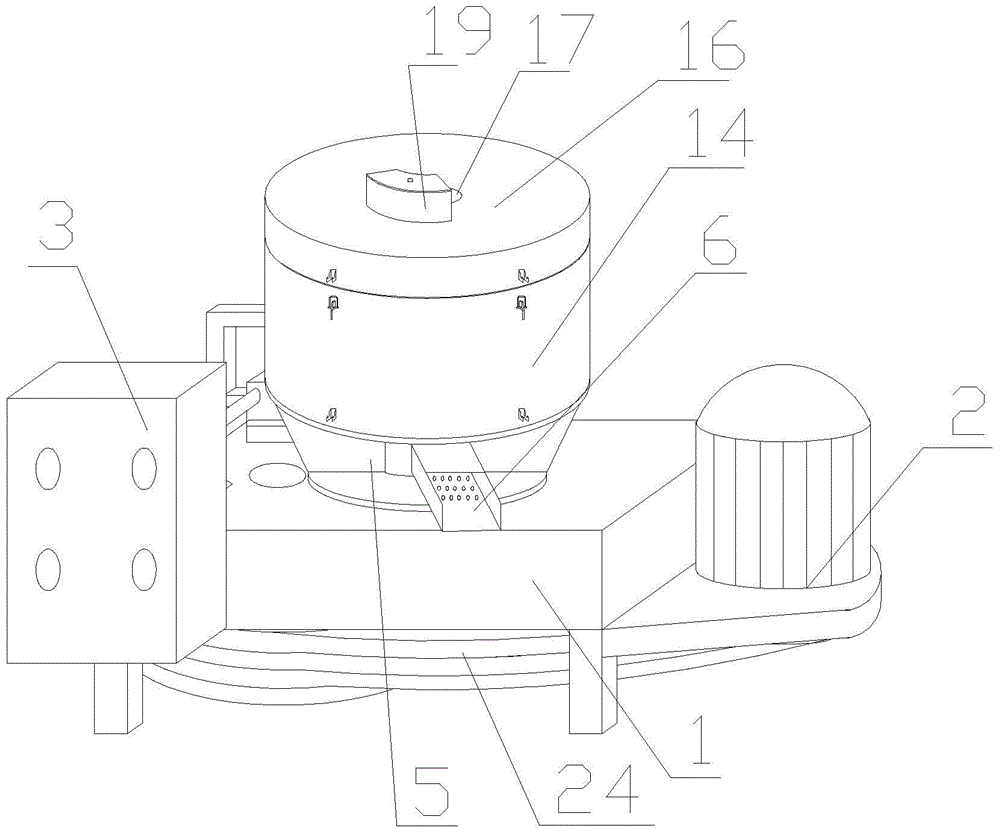

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

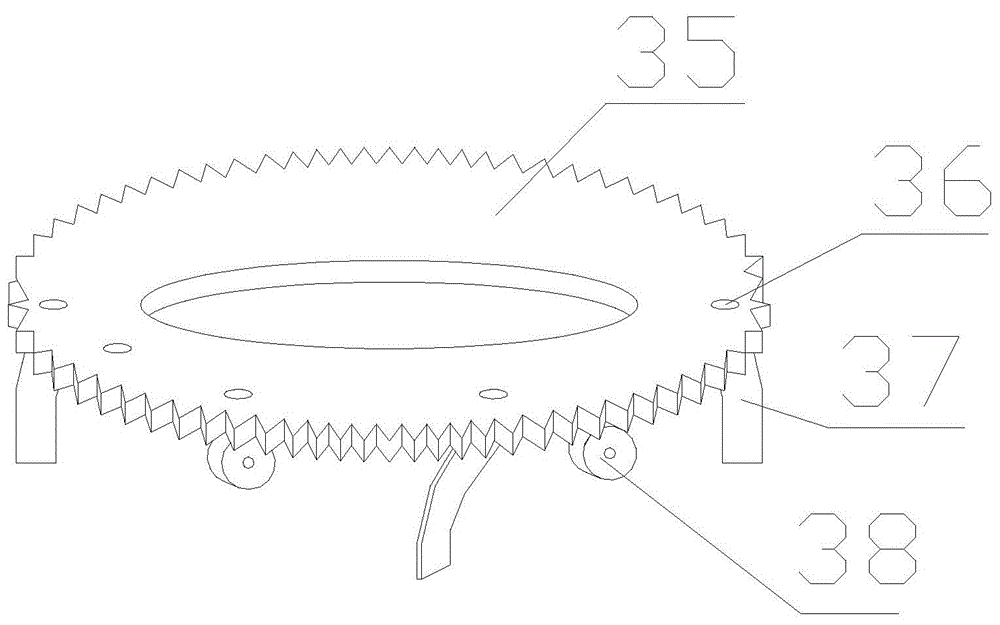

[0019] The invention provides a horizontal biomass granulator, comprising a chassis frame 1, a motor 2 is provided at one end of the chassis frame 1, a distribution box 3 is provided at the other end of the chassis frame 1, and a power distribution box 3 is provided at the bottom end of the chassis frame 1 The main shaft transmission mechanism 4, the chassis frame 1 is provided with a head plate 5, the discharge end of the head plate 5 is connected with a discharge channel 6, the discharge end of the head plate 5 is provided with a material leakage port 7, and the head plate 5 is clamped with a grinding disc 8, and a rotatable spindle mechanism 9 is installed in the head disc 5 through a bearing 21. The grinding disc 8 is provided with a scraping support mechanism 10, and the scraping support mechanism 10 is provided with a A scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com