Acrolein oxidation to acrylic acid catalyst, preparation method and application of catalyst

A technology of catalyst and acrolein, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of low selectivity and yield of acrylic acid, and achieve improvement Reaction performance, good technical effect, effect of yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

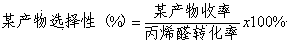

Image

Examples

Embodiment 1

[0052] 100 g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was added to 100 g of warm water at 70 °C, stirred to dissolve it completely, 68.6 g of 40% (wt.) silica sol, 63.3 g of 20% (wt.) aluminum sol and 16.6 g (NH 4 ) 6 H 5 [H 2 (WO 4 ) 6 ] to make material A.

[0053] 32.8 g Ce(NO 3 ) 3 ·6H 2 O was added to 20 grams of 70 ℃ hot water, stirred to dissolve, and then added 26.3 grams of Zr (NO 3 ) 4 ·6H 2 O, 31.9 g Cu (NO 3 ) 2 ·3H 2 O, 64.1 g, Bi (NO 3 ) 3 ·5H 2 O, 9.2 g CsNO 3 , 3.3 grams of KOH was dissolved to make material B.

[0054] Add 18.7 g NH to 50 g water 4 VO 3 and 18 grams of urea-forming material C.

[0055] Material B and C were successively added dropwise to material A under rapid stirring to form a catalyst slurry, which was stirred and aged at 80 °C for 2 hours, the slurry was dried at 120 °C to remove most of the water, and then extruded to obtain φ3. 5x3.5mm cylindrical object, and then calcined at high temperature to obtain the finished catalyst,...

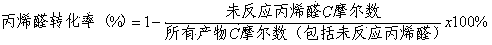

Embodiment 2~11

[0058] The catalyst was prepared according to the steps of Example 1, except that the catalyst preparation conditions were changed, and the type and amount of pore-forming compounds were added. The specific results are listed in Table 1. Under the same evaluation conditions as Example 1, the reaction evaluation results are listed in Table 2. .

[0059] Table 1

[0060]

[0061] Table 2

[0062] Acrylic acid yield (%) Acrylic acid selectivity (%) Acrolein conversion rate (%) Comparative example 1 95.8 98.0 97.8 Comparative example 2 96.4 98.3 98.1 Example 1 97.4 98.9 98.5 Example 2 97.3 98.7 98.6 Example 3 98.8 99.3 99.5 Example 4 97.6 99.1 98.5 Example 5 95.6 97.0 98.6 Example 6 98.7 99.1 99.6 Example 7 96.6 98.2 98.4 Example 8 97.7 98.7 99.0 Example 9 97.3 98.8 98.5 Example 10 96.5 99.1 97.4 Example 11 98.2 98.9 99.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com