Herringbone upright structure small-size numerically controlled milling machine

A CNC milling machine and herringbone technology, applied in the field of CNC milling machines, can solve problems such as low precision, unreasonable structural layout, and weak rigidity of the machine tool, and achieve the effects of improved machine tool performance, convenient machine tool assembly, and simple column structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

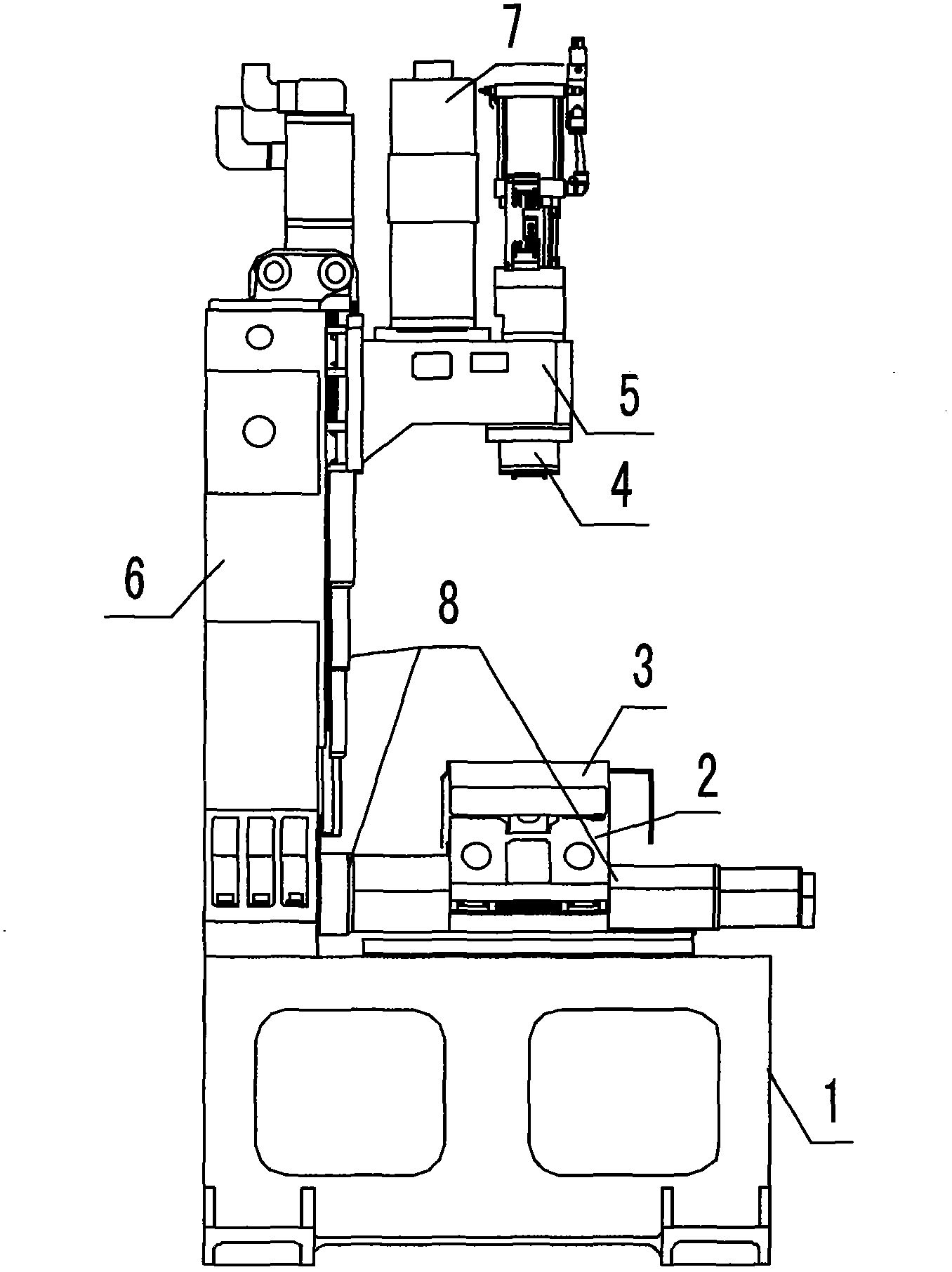

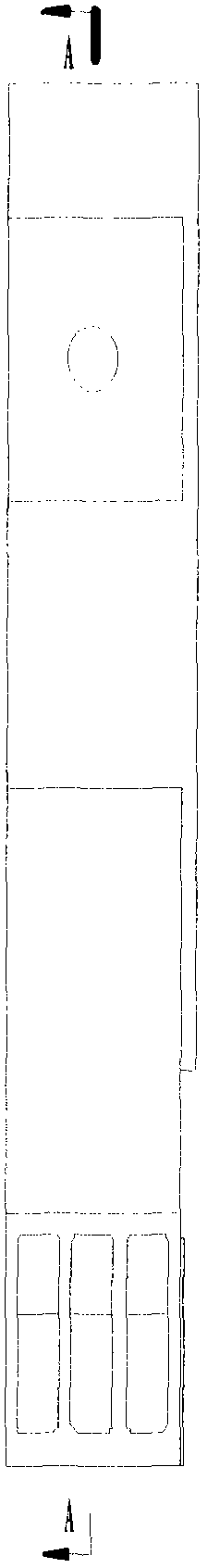

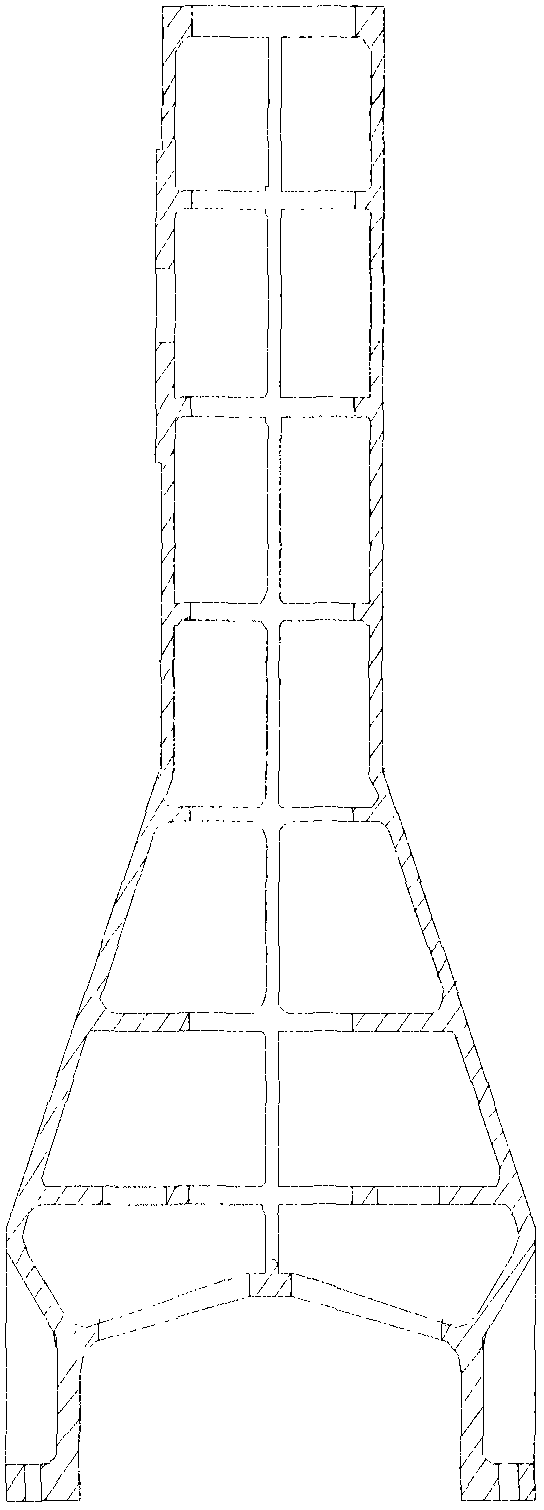

[0014] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a small CNC milling machine with a herringbone column structure includes a base mechanism 1, a middle sliding seat mechanism 2, a workbench mechanism 3, a spindle mechanism 4, a spindle box mechanism 5, a column structure 6, a main motor structure 7, and an inner protection Mechanism 8 is characterized in that: the table mechanism 3 performs linear motion in the X and Y directions, the headstock mechanism 5 performs linear motion in the Z direction, and the column structure 6 is connected with the base structure 1 through 6 fixing screws; The column structure 6 is connected with the headstock mechanism 5 through the Z-direction rail and the Z-direction screw. The headstock mechanism 5 moves up and down on the column structure 6; the inner protection structure 8 and the column...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap