A fully automatic assembly equipment for cd and vcd laser head components

A technology of assembly equipment and laser head, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high production cost, low assembly efficiency, and high work intensity, so as to improve market competitiveness, reasonable structural design, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

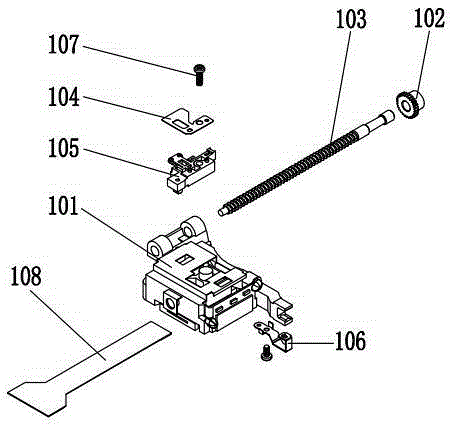

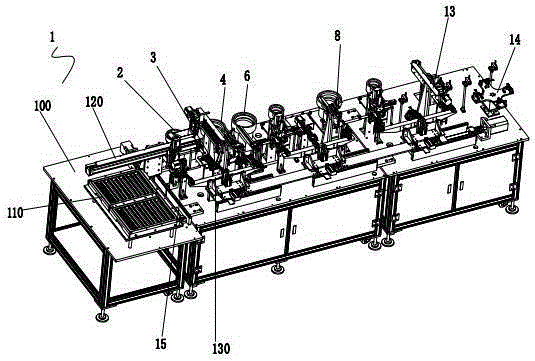

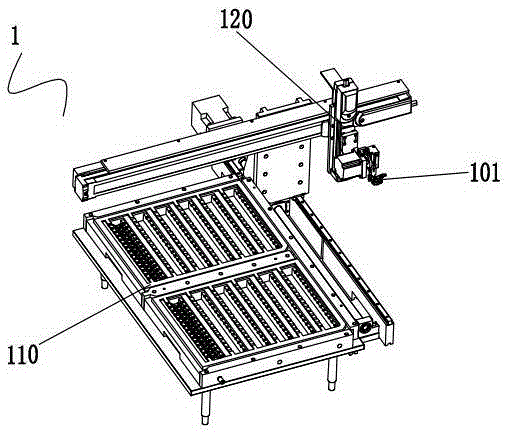

[0030] Such as Figure 2-10 As shown, a fully automatic assembly equipment for CD and VCD laser head assemblies includes a frame and a workbench 100 arranged on the frame, and the workbench 100 is provided with a laser head feeding mechanism 1 for conveying the laser head 101, a conveying gear 102 gear feeding mechanism 2, screw mandrel 103 is assembled into the screw mandrel mechanism of laser head 101 3, the screw mandrel guide plate feeding mechanism of conveying screw mandrel guide plate 105, the screw mandrel guide plate 105 is assembled into the screw mandrel guide plate of laser head 101 Assembling mechanism 5, the feed plate feeding mechanism 6 that conveys feed plate 104, feed plate 104 is assembled into the feed plate assembly mechanism 7 of laser head 101, the bald head auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com