Cross beam type power assembly suspension device

A powertrain and beam technology, which is applied in power units, control units, jet propulsion units, etc., can solve the problems of poor vibration isolation performance and occupying space for bodywork, and achieve good vibration isolation performance, prolong service life, and enhance lateral Effects of torsional stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

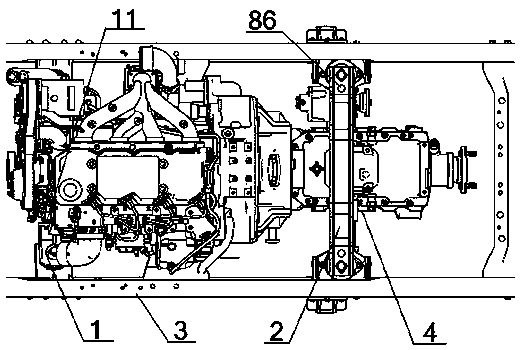

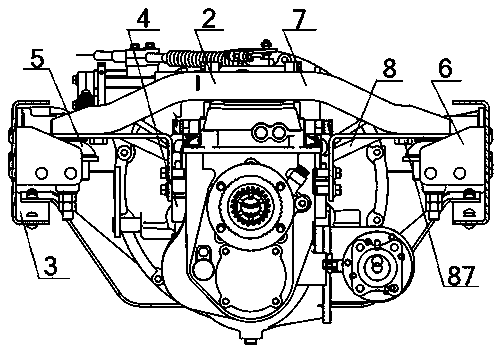

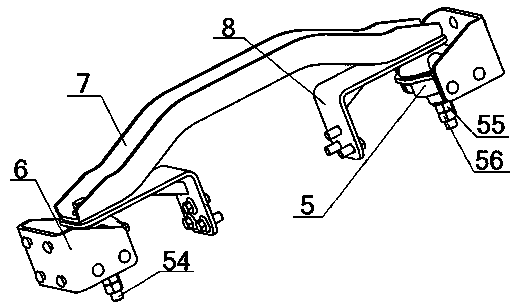

[0054] A beam-type powertrain suspension device, comprising a front suspension 1 and a rear suspension 2, one end of the front suspension 1 is fixedly connected to the engine casing 11, and the other end of the front suspension 1 is connected to the vehicle frame longitudinal beam 3 is fixedly connected, the middle part of the rear suspension 2 is fixedly connected with the gearbox housing side plate 4, and the two ends of the rear suspension 2 are fixedly connected with the frame longitudinal beam 3; the middle part of the rear suspension 2 is connected with the gearbox The middle part of the housing side plate 4 is fixedly connected; the rear suspension 2 includes a mushroom-shaped cushion assembly 5, a rear suspension bracket 6 and a bow-shaped crossbeam 7, and the two ends of the bow-shaped crossbeam 7 are connected to two mushroom-shaped crossbeams respectively. The top of the mushroom-shaped cushion assembly 5 is fixedly connected, the middle part of the mushroom-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com