Optical glass

A technology of optical glass and optical components, applied in optics, optical components, instruments, etc., can solve the problems of easy devitrification of glass, low viscosity of glass, etc., and achieve the effect of excellent devitrification resistance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

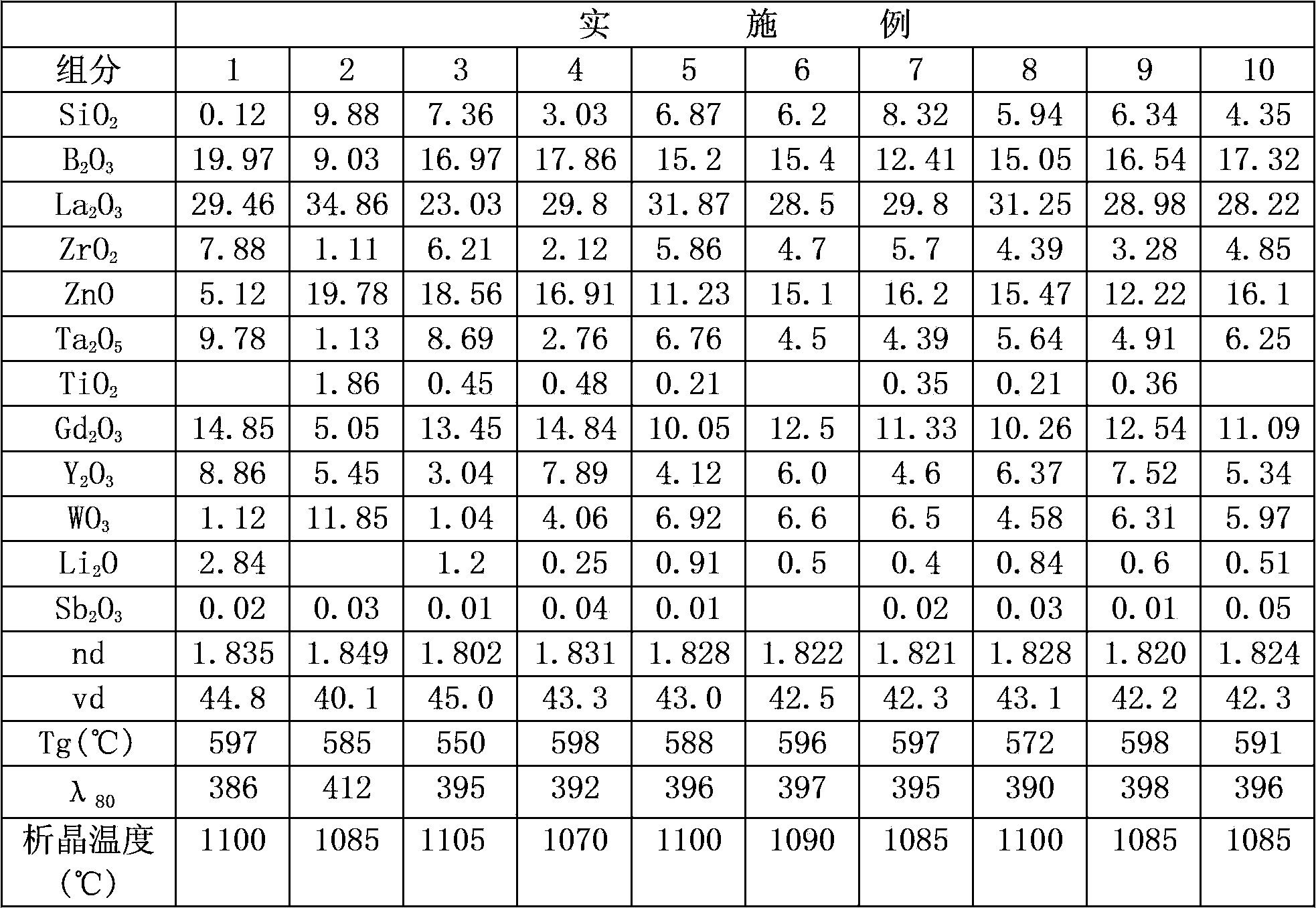

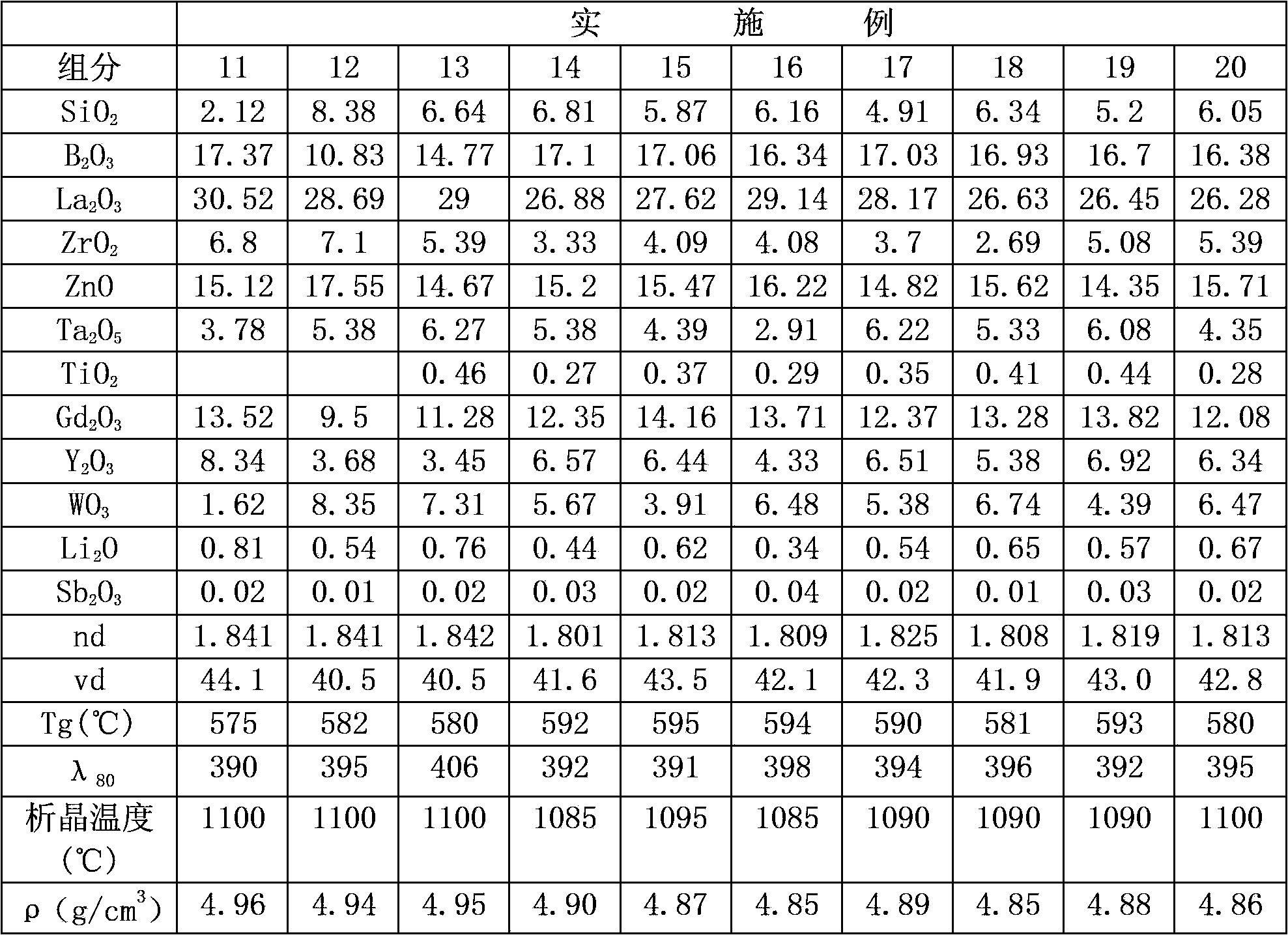

[0055] Embodiments of the precision molded optical glass of the present invention will be described below. It should be noted that these examples do not limit the scope of the present invention.

[0056] The optical glasses (Examples 1 to 30) shown in Tables 1 to 3 were obtained by weighing and mixing common raw materials for optical glasses (such as oxides, hydroxides, carbonic acid salt, nitrate and fluoride), the mixed raw materials are placed in a platinum crucible, melted at a temperature of 1100-1300 ° C, and after melting, clarification and homogenization, a homogeneous product without bubbles and undissolved substances is obtained. High-quality molten glass is formed by casting the molten glass in a mold and annealing it.

[0057] The composition, refractive index (nd), Abbe's number (vd), and glass transition temperature (Tg) of Examples 1 to 30 of the present invention are shown in Tables 1 to 3 together. In these tables, the composition of each component is expres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com