Coal pillar-free coal mining method with integrated support for mining with flexible cover support in steeply inclined medium-thick coal seam

A flexible shielding support, thick coal seam technology, applied in ground mining, earth-moving drilling, underground mining, etc., can solve problems such as threatening worker safety, increasing workload, easily generating impact loads, etc., achieving safe and effective roof management and reducing support The effect of stress, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

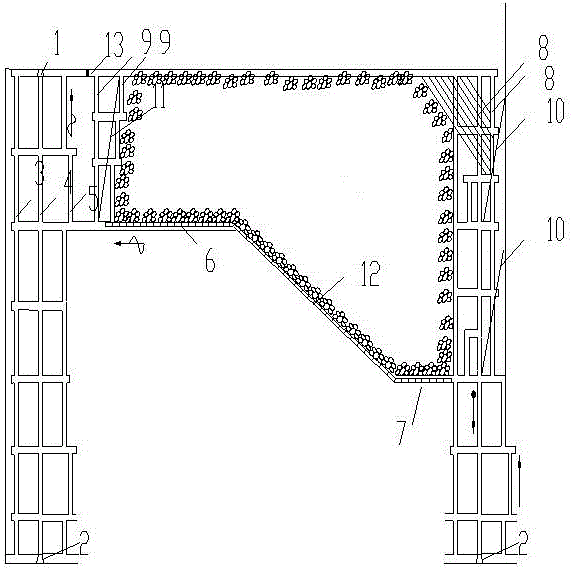

[0045] A coal pillar-free coal mining method with integrated support for mining with flexible cover supports in steeply inclined medium-thick coal seams,

[0046] Firstly, relevant operation eyes are opened at both ends of the coal seam, such as figure 1 As shown: 1 is the return air stone gate of the mining area, 2 is the transportation stone gate of the mining area, 3 is the operation eye, 4 is the coal slip eye, 5 is the pedestrian eye, 6 is the section return air lane, 7 is the section transportation lane, 8 The initial mining roadway, 9 is the closing eye, 10 is the moving track line of the tail of the frame, 11 is the moving track line of the head of the frame, 12 is the coal mining face, 13 is the permanent sealing wall, and the arrow with dots is the direction of coal block transportation.

[0047] Before mining, excavate the return air entry at the top of the coal seam, excavate the section return air entry at intervals below the coal seam, and lay transportation equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com