Water jacket structure for cylinder head

A cylinder head and water jacket technology, applied in the direction of cylinder head, cylinder, engine cooling, etc., can solve the problems of water jacket coolant retention and coolant flow increase, and achieve the effect of efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

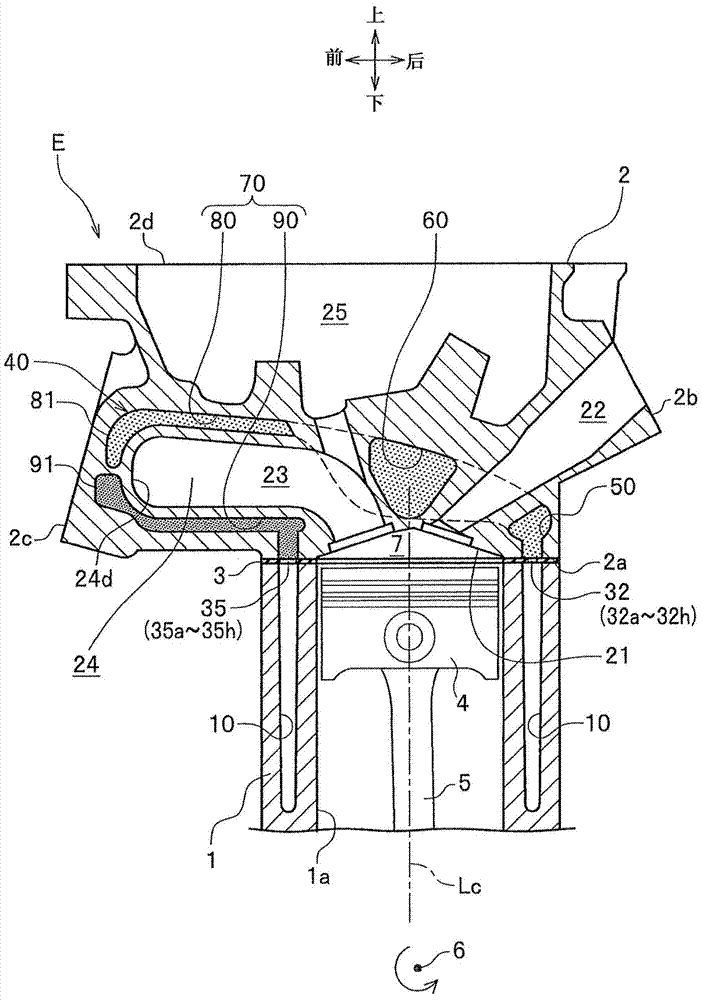

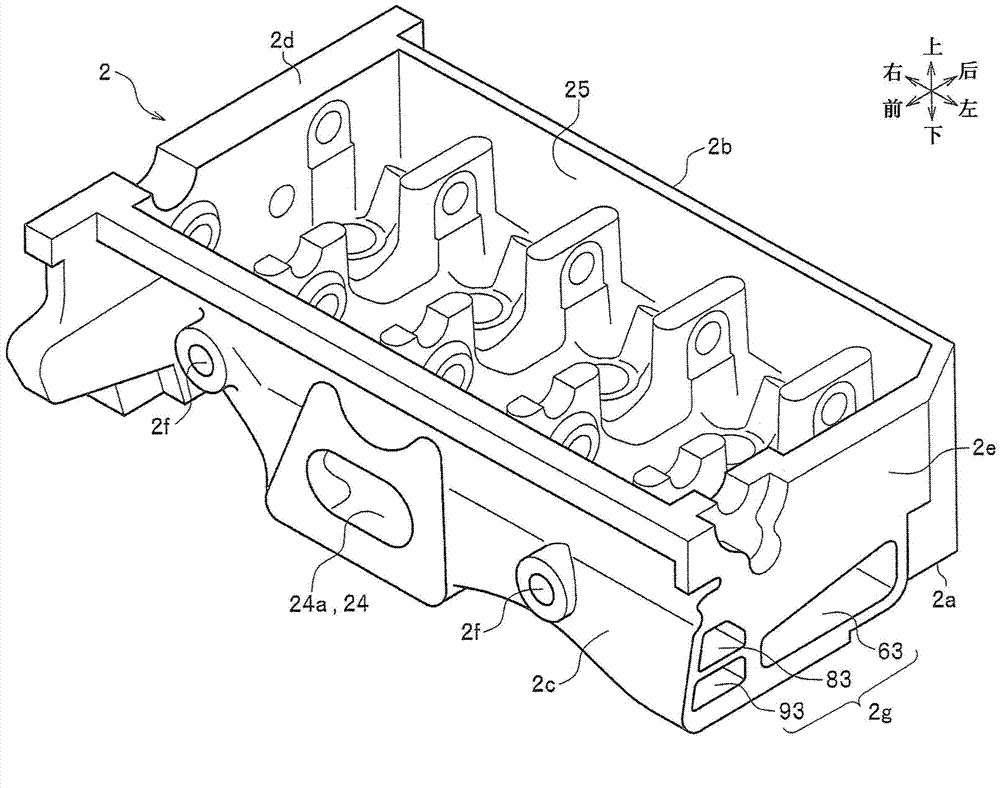

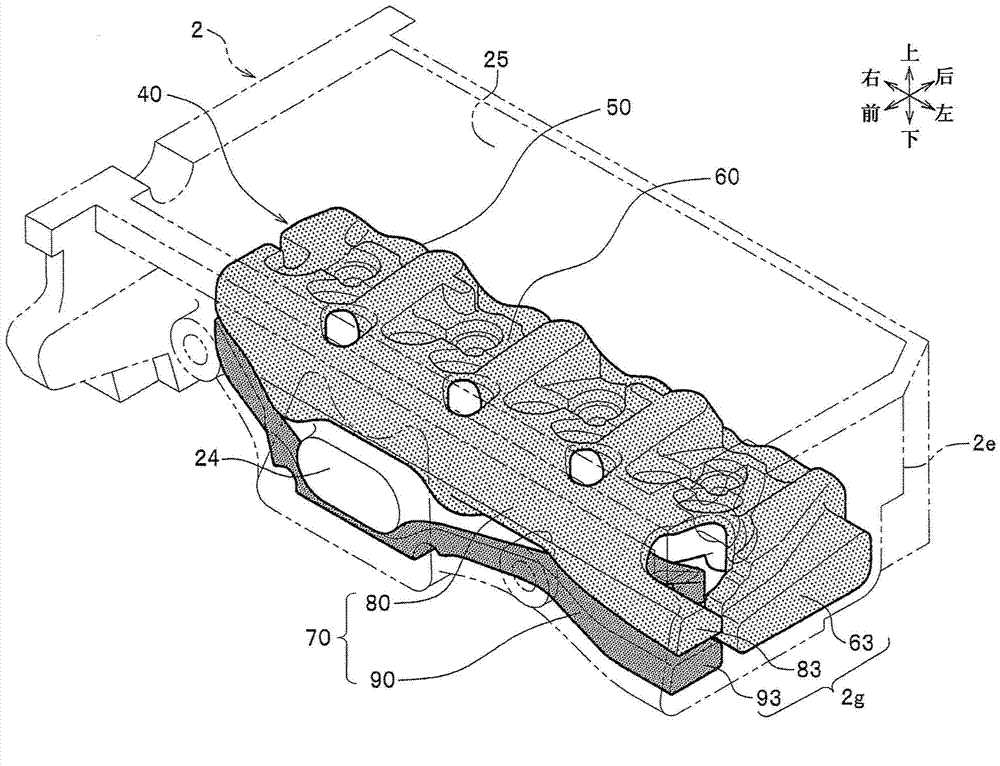

[0090] For the implementation of the present invention, refer to Figure 1 to Figure 12It demonstrates in detail. In the description, the same reference numerals are assigned to the same members, and overlapping descriptions are omitted. In addition, when describing a direction, as shown in each drawing, it demonstrates based on the state which installed the internal combustion engine E in a vehicle, front, rear, left, right, up and down.

[0091] figure 1 It is a cross-sectional view of an internal combustion engine having a water jacket structure of a cylinder head according to this embodiment.

[0092] Such as figure 1 As shown, the internal combustion engine E to which the present invention is applied has an internal combustion engine main body, and the internal combustion engine main body has: a cylinder block 1, which is, for example, four cylinders 1a (in figure 1 Only one of them is shown in the figure) are arranged in line and arranged integrally; the cylinder hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com