A pressurized humidification device for laboratory piping system

A technology for a pipeline system and a humidification device, which is applied in the field of pressurized humidification devices, can solve problems such as inability to realize humidification of pipeline equipment systems, and achieve the effects of ensuring stability, reducing entrainment, and increasing gas-liquid contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

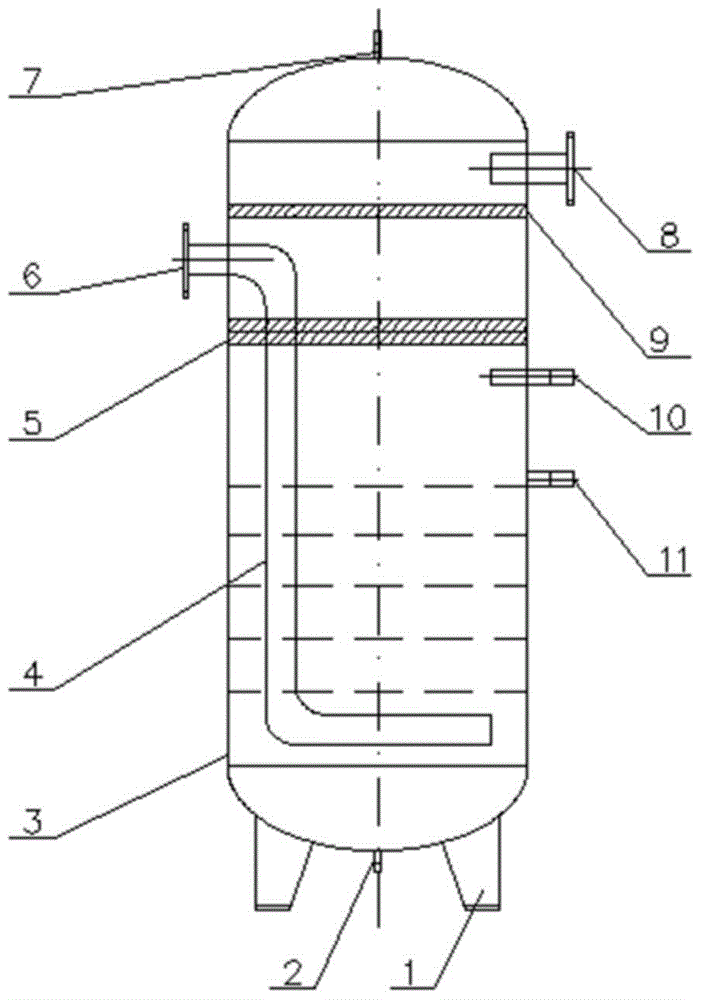

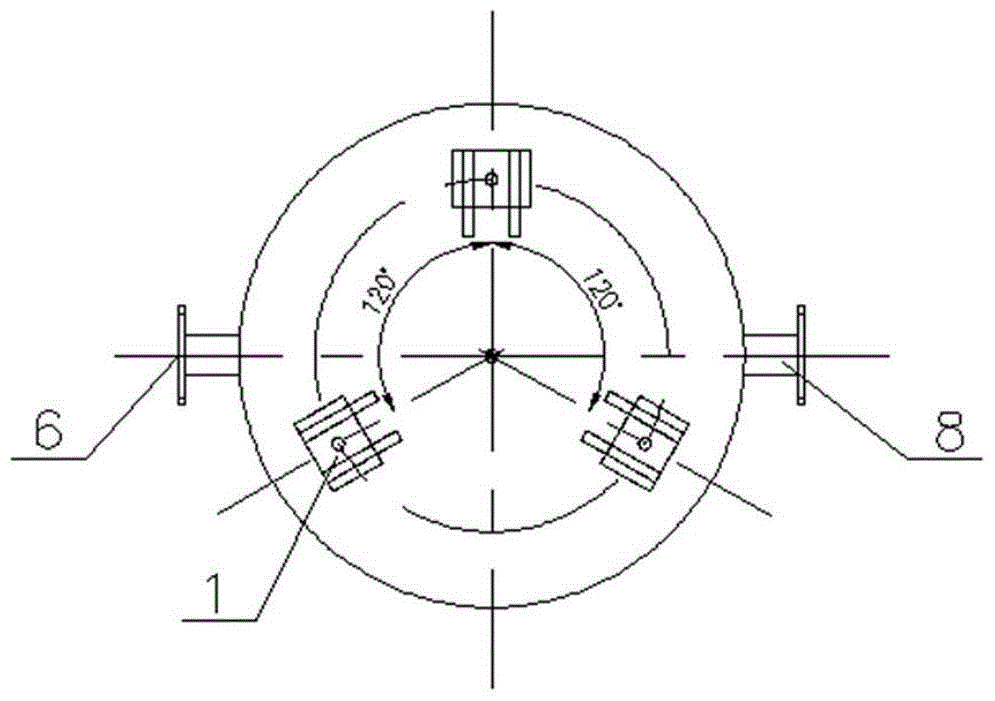

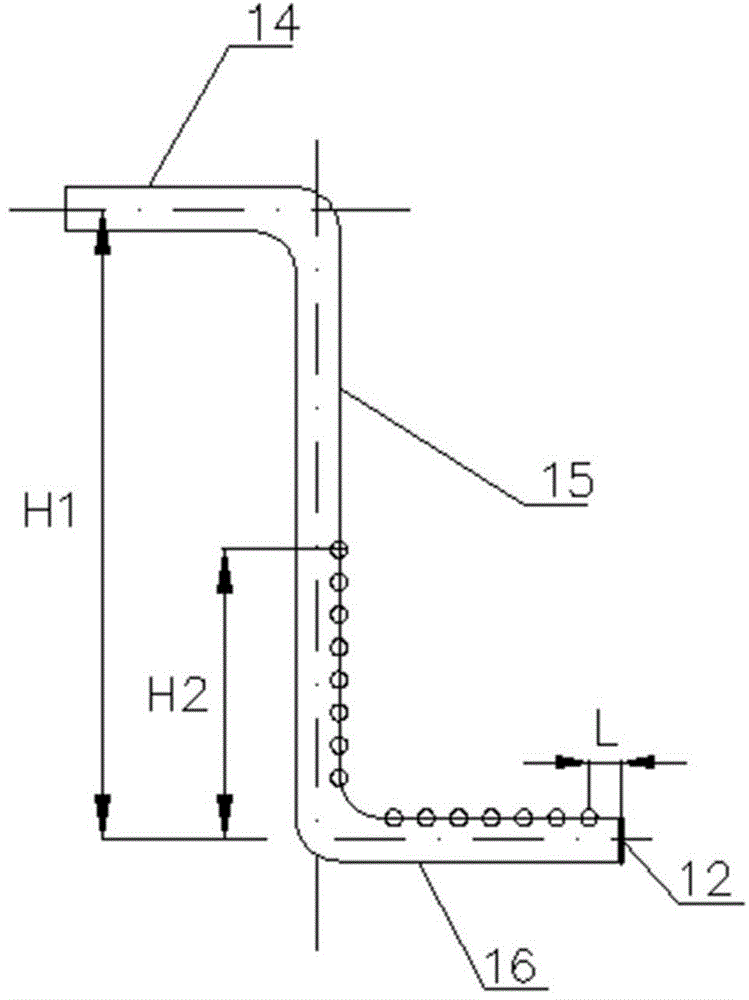

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the pressurized humidification device used in the laboratory pipeline system includes: drain pipe 2, humidification tank 3, humidification pipeline 4, primary capture net 5, pressure relief valve 7, moisture outlet pipeline 8, secondary capture Net 9, water inlet pipe 10 and liquid level control valve 11;

[0015] The humidifying tank 3 is a stainless steel cylindrical shell with a hemispherical shell at the top and bottom. The diameter of the humidifying tank 3 is 1000mm-3500mm, the wall thickness is 4mm-20mm, and the height is 2000mm-4200mm; the top of the humidifying tank 3 is installed for pressure relief. Valve 7, when the pressure in the humidification tank is higher than the design maximum pressure, the pressure relief valve is opened.

[0016] Drainage pipe 2 and support 1 are installed at the bottom of humidification tank 3, and the number of support 1 is 3, which are evenly arranged in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com